It's that time of year that i throw money at a new ebike product and test it to see if it lives up to the hype..

A couple members here mentioned that a few companies were offering 1500w rated hub motors for sale and i had to investigate.

reference threads:

Ebikeling "wide" 1500w kit

Curios about this 35mm 1500W motor

Motor kit link:

26 inch 48V 52V 1500W rear hub motor - bike conversion kit

Standalone motor link ( as of writing, shows incorrect graph, but still the same motor ) 26 inch 48V 52V 1500W rear electric bike motor wheel

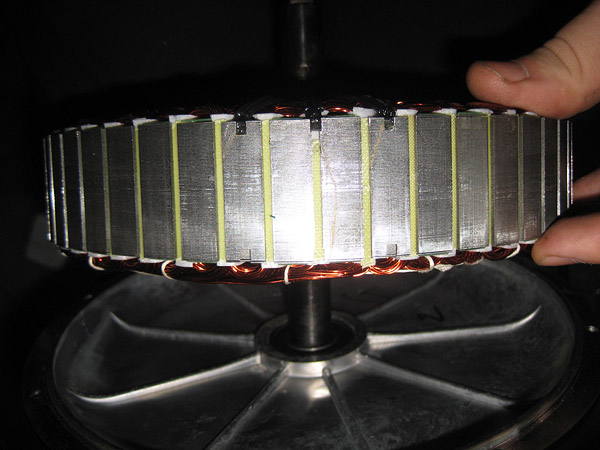

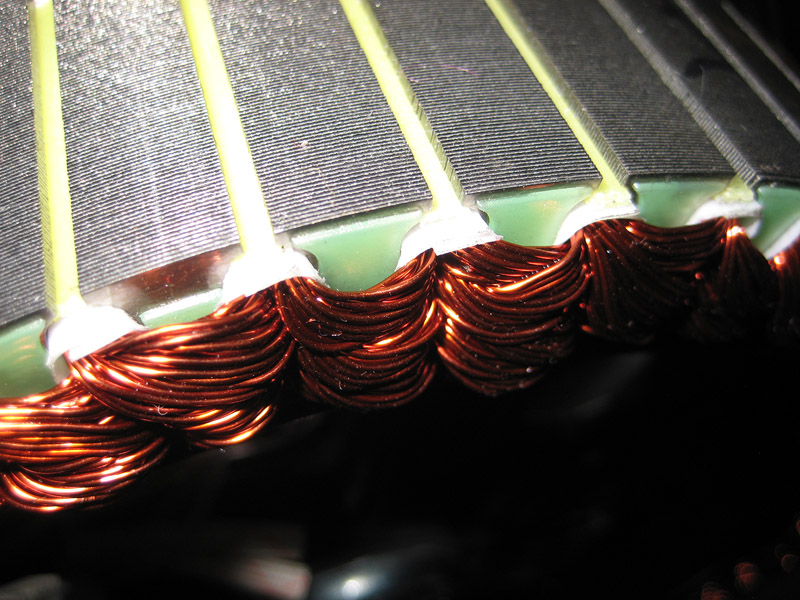

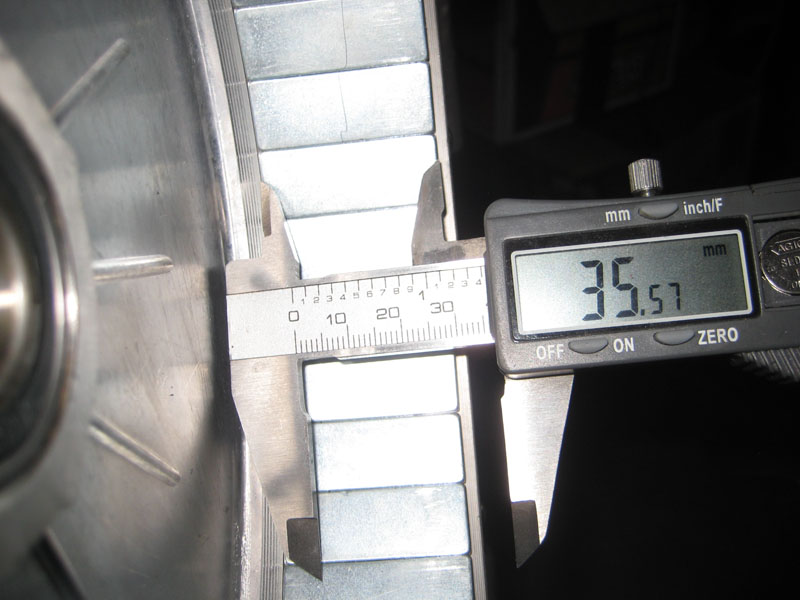

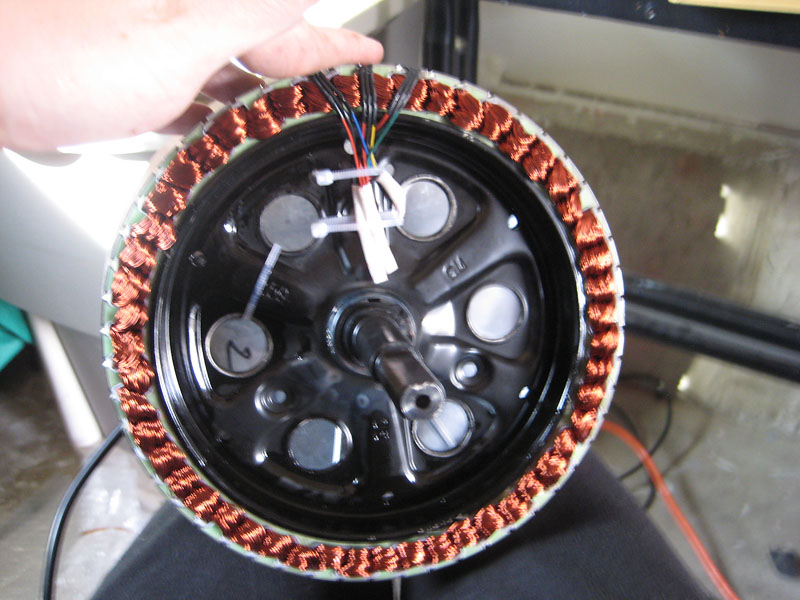

These 35mm stator motors.. so they would be similar in dimensions as the Crystalyte HS35xx series of motors.

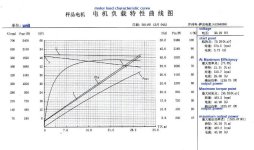

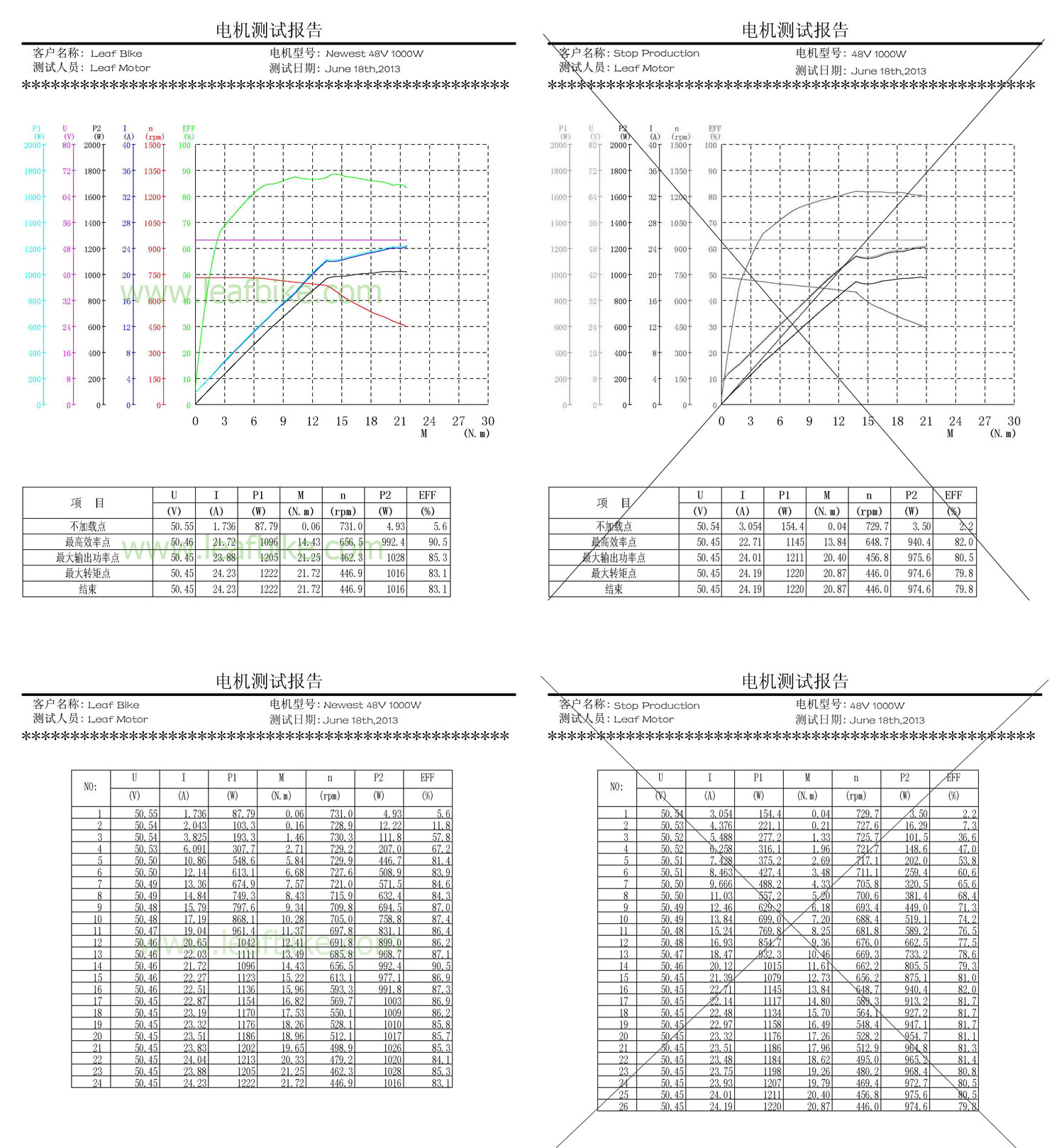

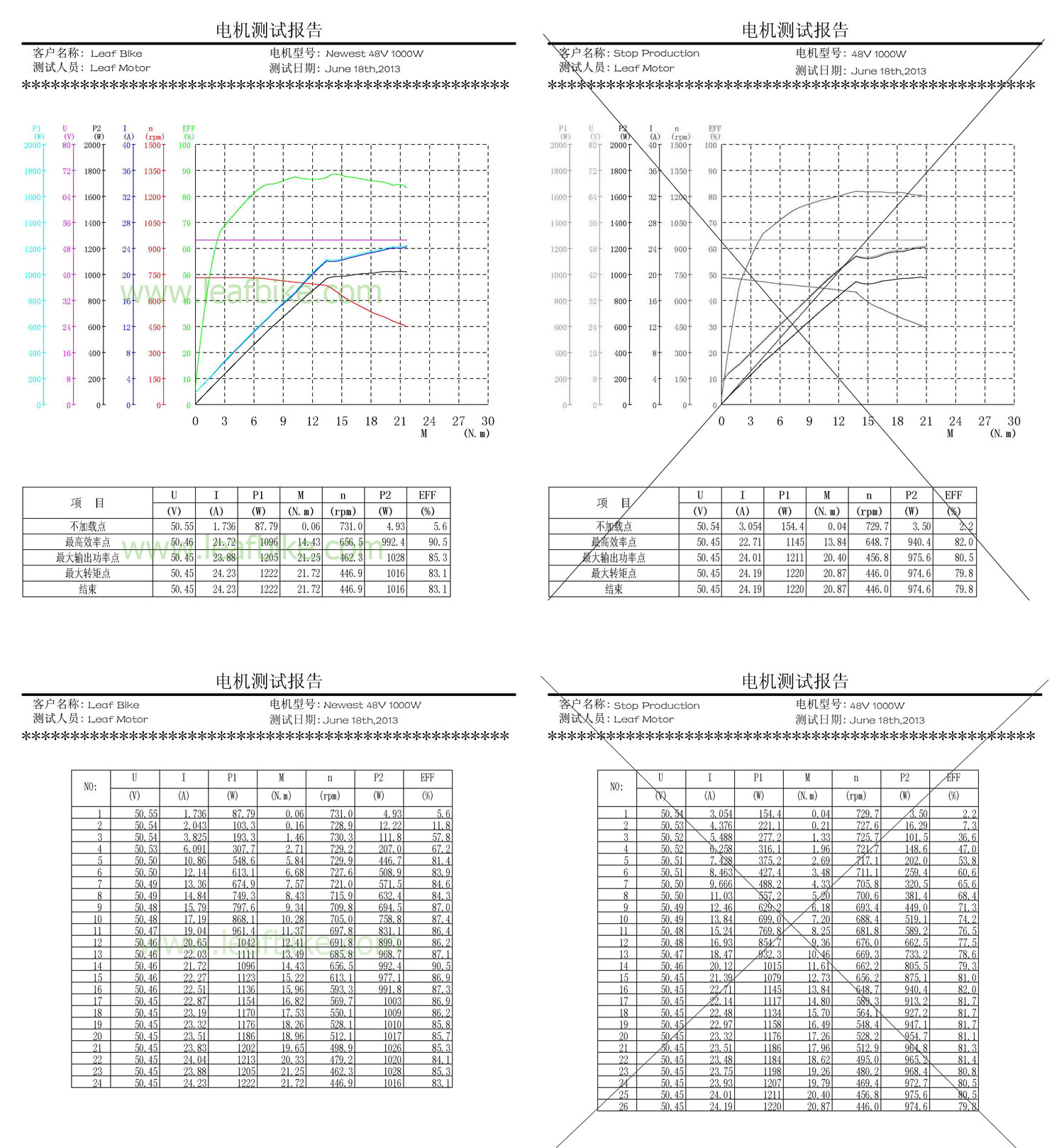

Stated efficiency seems to vary per vendor.. from a maximum of 80% to a maximum of 90%.

Leaf motor makes a claim about this motor as having higher grade laminations. I suspect this could mean ~0.33mm laminations, which would somewhat explain the high efficiency claim of these motors. They make a claim of difference in efficiency for their newer 1000W motor as well. So, i figure this may be legit

Here is the data on their new motor.

48V 52V 1500W rear spoke hub motor - electric bike motor

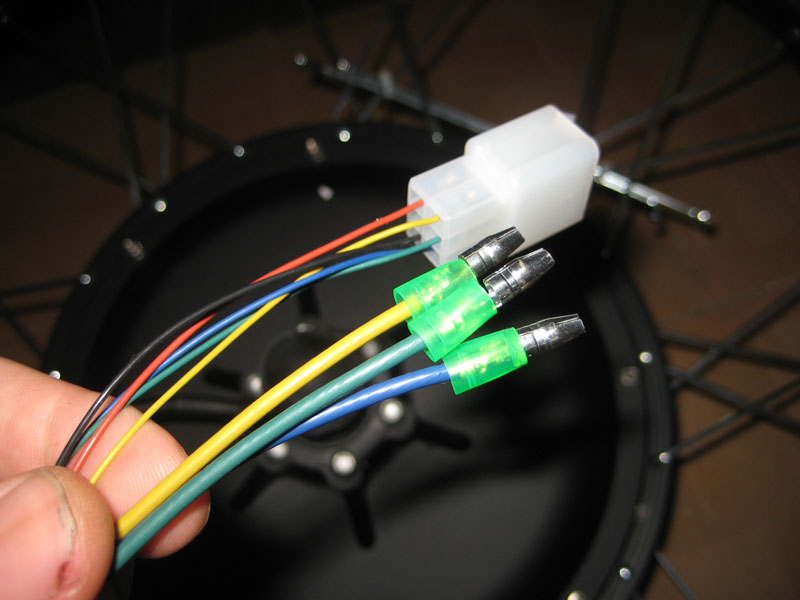

So, i have ordered up the motor.. i asked for a 24mm internal width rim and they spoked it up at no additional cost, so that's cool. It's in transit and i should get it in a week or two.

Worst case scenario: This company is full of crap and it's really a 80% efficient motor. The motor is still useful, but i will talk crap about them eternally. The axle may be actually be 142mm since many of these companies aren't honest about that... we'll see.

Best case scenario: looking at the spec sheet, this motor's power would be understated by quite a bit. At 2000w input, it should be making around 200w of heat; that seems like a sustainable constant power level. I have something that is almost as powerful as a Crystalyte HS40xx and i pay myself on the back for being a first adopter.

More on this later.

edit: note after the fact:

If you order the default winding, the 4T..

For a 26" wheel, you will want a controller and battery capable of pushing 60 amps continuous during acceleration or hill climbing in order to hit the top speed of the motor and have decent torque.

60A x 48V = 2880W peak.

Your continuous wattage at 100% speed will be about 2000W, or approx. 41A continuous.

You'll want nothing smaller than a 12FET 4011, or preferably 3077 FET controller in order to do this. I run an 18FET 4011 controller myself with this winding, because i wanted large amounts of thermal overhead, as i run about 90-100 amps. Even the 12FET 3077 ( lowest resistance FET type is the 3077 ) would get hot on 80A.

For this winding, i would use either a RC Lipo type pack above 20AH or A123 pack around 20AH as well in order to deliver the needed current. 20C Lipo would work.

If you want something other than the two above chemistries, you're going to need 40-60AH worth most likely, if you're dealing with a 2C-5C chemistry. 1C is out of the question unless you can figure out how to jam 50-60AH into the triangle.

The 4T is an amp guzzler, not a volt guzzler..

Another note after the fact:

Here are some figures for speed per volt in a 26" wheel:

I measured my no load at 645rpm at 49 volts ( 13.16 kv ), so keep that in mind. By that math:

4T: 631rpm / 48v = 13.16 kv ( measurement by me, adjusted down 1 volt )

5T: 485rpm / 48v = 10.1 kv ( fluxshifter's measurement )

6T: 336rpm / 48v = 7kv ( assumption based on 3kV steps per winding )

Rough idea of 48v speeds in a 26" wheel:

4T: 39mph ( observed )

5T: 30mph ( calculated but not observed )

6T: 21mph ( assumed )

A couple members here mentioned that a few companies were offering 1500w rated hub motors for sale and i had to investigate.

reference threads:

Ebikeling "wide" 1500w kit

Curios about this 35mm 1500W motor

Motor kit link:

26 inch 48V 52V 1500W rear hub motor - bike conversion kit

Standalone motor link ( as of writing, shows incorrect graph, but still the same motor ) 26 inch 48V 52V 1500W rear electric bike motor wheel

These 35mm stator motors.. so they would be similar in dimensions as the Crystalyte HS35xx series of motors.

Stated efficiency seems to vary per vendor.. from a maximum of 80% to a maximum of 90%.

Leaf motor makes a claim about this motor as having higher grade laminations. I suspect this could mean ~0.33mm laminations, which would somewhat explain the high efficiency claim of these motors. They make a claim of difference in efficiency for their newer 1000W motor as well. So, i figure this may be legit

Here is the data on their new motor.

48V 52V 1500W rear spoke hub motor - electric bike motor

So, i have ordered up the motor.. i asked for a 24mm internal width rim and they spoked it up at no additional cost, so that's cool. It's in transit and i should get it in a week or two.

Worst case scenario: This company is full of crap and it's really a 80% efficient motor. The motor is still useful, but i will talk crap about them eternally. The axle may be actually be 142mm since many of these companies aren't honest about that... we'll see.

Best case scenario: looking at the spec sheet, this motor's power would be understated by quite a bit. At 2000w input, it should be making around 200w of heat; that seems like a sustainable constant power level. I have something that is almost as powerful as a Crystalyte HS40xx and i pay myself on the back for being a first adopter.

edit: note after the fact:

If you order the default winding, the 4T..

For a 26" wheel, you will want a controller and battery capable of pushing 60 amps continuous during acceleration or hill climbing in order to hit the top speed of the motor and have decent torque.

60A x 48V = 2880W peak.

Your continuous wattage at 100% speed will be about 2000W, or approx. 41A continuous.

You'll want nothing smaller than a 12FET 4011, or preferably 3077 FET controller in order to do this. I run an 18FET 4011 controller myself with this winding, because i wanted large amounts of thermal overhead, as i run about 90-100 amps. Even the 12FET 3077 ( lowest resistance FET type is the 3077 ) would get hot on 80A.

For this winding, i would use either a RC Lipo type pack above 20AH or A123 pack around 20AH as well in order to deliver the needed current. 20C Lipo would work.

If you want something other than the two above chemistries, you're going to need 40-60AH worth most likely, if you're dealing with a 2C-5C chemistry. 1C is out of the question unless you can figure out how to jam 50-60AH into the triangle.

The 4T is an amp guzzler, not a volt guzzler..

Another note after the fact:

Here are some figures for speed per volt in a 26" wheel:

I measured my no load at 645rpm at 49 volts ( 13.16 kv ), so keep that in mind. By that math:

4T: 631rpm / 48v = 13.16 kv ( measurement by me, adjusted down 1 volt )

5T: 485rpm / 48v = 10.1 kv ( fluxshifter's measurement )

6T: 336rpm / 48v = 7kv ( assumption based on 3kV steps per winding )

Rough idea of 48v speeds in a 26" wheel:

4T: 39mph ( observed )

5T: 30mph ( calculated but not observed )

6T: 21mph ( assumed )

Last edited: