Hi Guys, I'm building a molicel 21700 pack 20s8p.. I'm struggling with calculating nickel strip sizes.. I've done some homework!!

But still not happy to proceed with the build..

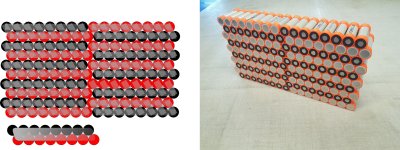

What i'm thinking is pieces of 8-10 mm x .2mm strip made up in the arrangement attached or maybe down to .15 for the parrallel links. alternatively a single .2 patch as in the pic. my goals are over 150 battery amps, it would be good to make it 250 amp tolerant as I have the big Nuc controller that I will put on the raptor at some point.

I realise i will have to beef up the bus bar connecting both sections of the battery and the termination ends of of the series +- ... Many thanks in advance

Cheers

Jon

But still not happy to proceed with the build..

What i'm thinking is pieces of 8-10 mm x .2mm strip made up in the arrangement attached or maybe down to .15 for the parrallel links. alternatively a single .2 patch as in the pic. my goals are over 150 battery amps, it would be good to make it 250 amp tolerant as I have the big Nuc controller that I will put on the raptor at some point.

I realise i will have to beef up the bus bar connecting both sections of the battery and the termination ends of of the series +- ... Many thanks in advance

Cheers

Jon