brownj24

1 mW

- Joined

- Aug 22, 2020

- Messages

- 19

required info:

20S13P pack

Samsung 35E cells, rated at 8 amp continuous

Maximum peak current will be limited to 50A, max continuous 40A (so under 0.5C discharge rate)

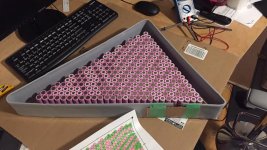

I've laid out my battery to maximize the space in my mountain bike frame.

This has caused some odd and inconsistent shapes for parallel groups, but was laid out this way to maximize the number of nickel strip cell-to-cell connections for the series connections. Even with this layout, the lowest cell-to-cell nickel strip connections between two parallel groups will be 7.

so 50A current load, and at least 7 connection points, I calculated that I will need nickel strips rated to each carry roughly 7.2 amps. (8 mm wide and 0.2 mm thick, I think will be acceptable).

Questions:

1) For the parallel groups that have 13 cells each, but only 7 cell-to-cell connection points between groups (due to shape), do I need to beef up the parallel connections for the outlying cells? Will there be more stress put on those parallel connections now as they flow to the series connection point?

2) Does it make sense to connect two cells of one parallel group to one cell in the next parallel group, for example at one of the corners where one parallel group wraps around another?

3) When not all parallel groups have the same amount of series connection points (even with the proper amount of nickel), am I risking added resistance or other issues that could affect the performance/longevity of this expensive pack?

Bonus question: Would love your input on my layout before I glue them. Do you see any obvious errors?

Thank you!!

Jeremiah

20S13P pack

Samsung 35E cells, rated at 8 amp continuous

Maximum peak current will be limited to 50A, max continuous 40A (so under 0.5C discharge rate)

I've laid out my battery to maximize the space in my mountain bike frame.

This has caused some odd and inconsistent shapes for parallel groups, but was laid out this way to maximize the number of nickel strip cell-to-cell connections for the series connections. Even with this layout, the lowest cell-to-cell nickel strip connections between two parallel groups will be 7.

so 50A current load, and at least 7 connection points, I calculated that I will need nickel strips rated to each carry roughly 7.2 amps. (8 mm wide and 0.2 mm thick, I think will be acceptable).

Questions:

1) For the parallel groups that have 13 cells each, but only 7 cell-to-cell connection points between groups (due to shape), do I need to beef up the parallel connections for the outlying cells? Will there be more stress put on those parallel connections now as they flow to the series connection point?

2) Does it make sense to connect two cells of one parallel group to one cell in the next parallel group, for example at one of the corners where one parallel group wraps around another?

3) When not all parallel groups have the same amount of series connection points (even with the proper amount of nickel), am I risking added resistance or other issues that could affect the performance/longevity of this expensive pack?

Bonus question: Would love your input on my layout before I glue them. Do you see any obvious errors?

Thank you!!

Jeremiah