Penobscot17

1 µW

- Joined

- Nov 4, 2020

- Messages

- 3

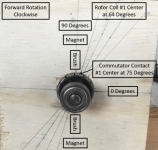

The common issue with trolling motors is that higher pitch boat propellers in that size range are usually right hand and trolling motors use left hand propellers. I am trying to determine the proper location of the brushes/commutator for for reverse rotation, and to make that correction by rotating the magnets on a Newport Vessels NV86. Rotation of the magnets is accomplished via an adapter ring to rotate the bolt pattern (see picture below of rotated mounting holes for the long bolts). By inspection, the brushes and magnets are aligned, and the commutator is advanced by 11 degrees from that same alignment (see picture below). In the OEM configuration, the no load speed (1,930 RPM) and current (1.4 Amps) are the same for both directions (already in neutral plane?). I rotated the magnets 22 degrees clockwise (from perspective of the motor diagram below). The rotated magnet configuration no load RPM and current remained the same for the reverse direction. However, the forward direction RPM increased to about 2,250, and so did the current (I lost my notes for this measurement). That raised questions about my method. Is the rotation of the magnets a viable method, how can I calculate the proper rotation, and how can I verify that it was performed correctly? Is it possible that the motor is in the neutral plane already given the no load measurements vs. the geometry shown in the picture below?