Hi everyone,

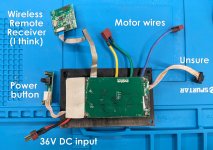

I have an Evolve Skateboards motor controller that I want to re-purpose to control a brushless motor in a cordless snow blower, rather than spend $60CAD on a new e-bike controller. The problem is, the skateboard motor controller is controlled via a wireless remote and I need to control it using the lever built into the Snow blower handle which is a simple on/off switch. Does anyone know how I could use this controller to power a motor without the wireless remote? I don't even need variable speed, just an on off switch. The controller is from an old Bamboo single motor Evolve board.

I have an Evolve Skateboards motor controller that I want to re-purpose to control a brushless motor in a cordless snow blower, rather than spend $60CAD on a new e-bike controller. The problem is, the skateboard motor controller is controlled via a wireless remote and I need to control it using the lever built into the Snow blower handle which is a simple on/off switch. Does anyone know how I could use this controller to power a motor without the wireless remote? I don't even need variable speed, just an on off switch. The controller is from an old Bamboo single motor Evolve board.