steveo

100 kW

Hey Everyone,

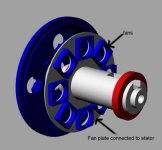

A very genours member on the forums will be donating there x5 motor side covers to me so i could expirement with air cooling my x5

I would like suggestions from you guys on the best way to do this with keeping any dirt outside the x 5 to avoid any internal damage..

Cross drilling some holes into the side covers seems to be the best way to do it! .. I think i have to find a place where they do brake routers and ask if they will do it for me?

Reason for cooling.

I have succussfully run 133v @ 46 amps for the last 2 weeks without any problems... other then my x5 hitting 100 degrees in about 10 mins of some hard riding (catching up to motorcycle guys lol)

I hope this will be able to give me some decent cooling if done right!

-steveo

A very genours member on the forums will be donating there x5 motor side covers to me so i could expirement with air cooling my x5

I would like suggestions from you guys on the best way to do this with keeping any dirt outside the x 5 to avoid any internal damage..

Cross drilling some holes into the side covers seems to be the best way to do it! .. I think i have to find a place where they do brake routers and ask if they will do it for me?

Reason for cooling.

I have succussfully run 133v @ 46 amps for the last 2 weeks without any problems... other then my x5 hitting 100 degrees in about 10 mins of some hard riding (catching up to motorcycle guys lol)

I hope this will be able to give me some decent cooling if done right!

-steveo