I'm not sure what you guys are doing with all that extra stuff on the desat circuit, it's not needed for desat to do it's job. Just tune it by hand after you build it (this is what I did and it can be done in about 30 mins if you have the parts on hand). The less extra stuff in a gate driver circuit, the less there is to go wrong in a very critical system.

First let's discuss the purpose of desat and I can sum it up in a very short example.

Holy shit something really really bad just happened... STOP!

Desaturation detection is something that is nice to have, but it's only there for when things go really bad, things you should have designed to avoid happening in the first place. The perfect desaturation circuit is one that is in place, has been tested and never ever gets used in it's entire life.

The amount of blanking time and how quickly the current rises in your load play the biggest role in how long the period is until it shuts down. Desat should only be active for a catastrophic event. That means the MOSFET only has to survive the high current situation for a few uS.

In order to fully understand if the desat can do it's job, you need to look at the data sheets and establish some parameters and then do the math.

We'll use and IRFP4468 for this example since you mentioned using it. I'll say it takes 5uS total until desat kicks in and shuts down the D-S connection based on experience with my TD350E (I've seen as short as 4uS).

1. RDSon worst case scenarios, 2.0mohm min and 2.6mOhm max. we know there is variation so we'll use 2.3mOhm for our calculations since the manufacturer is guaranteeing these tolerances are the range.

2. Maximum pulse current the MOSFET can sustain: 1120A (not says this is limited by max junction temperature which is 175c)

3. Find max amps for our wosrt case scenario of Tj= 175c, 5uS time. How many amps can the MOSFET handle? To the data sheet

3. Fig 8. Look up Vds vs Id at Tj=175, this is Fig. 8 on the spec sheet. Test condition is 25c on the case and 175 on the die, single pulse. We need a 5uS sec rating so we go to the area shorter than 100uS.

4. Fig 8. Looks like anything under 5uS is ok up to 1100A even. Yes this will have to be derated for case temp, but even if we derate and say 500A, we still have a very large range.

5. Now we have a good idea that the MOSFET will probably survive a 500A for at least 5uS under very bad conditions.

6. We need to know how much the RDSon changes from one temp to another, because this will effect the desat current. We'll say the Tj operating range in our device is -20C to 120C because over 125C the device life time is shortened and we want to keep headroom. That means our desat detection needs to operate over this range. RDSon changes as a positive temp coefficient, so hotter the MOSFET, the higher the RDSon. To figure this out we go lookc at Fig 4. Tj vs. Rds(on).

7. At -20 it's 0.75 of the 25c rated RDSon which we decided was going to be 2.3mOhm. At 120C it's about 1.85 times higher.

8. Our RDSon range is 2.3mOhm * 0.75 = 1.725mOhm and 2.3mOhm * 1.85 = 4.225mOhm. This is now the range the desat circuit has to worry about.

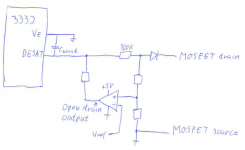

9. The desat is watching for V=IR. I don't see the Desat current in the datasheet spec, but I do see 240μA is used in the blanking time cap selection. This is most likely our desat current spec.

10. Now we need to know what our operating specs are. We'll say the MOSFET is going to see a max peak of 100A during normal operation. This means we need desaturation to happen higher than this point. We'll set it 1.5 times higher to allow us a max of 150A before it triggers desat.

11. Fun with ohms law. Our minimum desat votlage for and IRFP4468 at -20 degrees 1.725mOhm * 150A = 1.382V, a far cry from 6.5V.

12. At 25C we generate 1.443V and at 120c 1.638v. We now know that the desat circuit has to operate with a 1.443 to 1.638v.

13. Spec sheet says it can vary from 6 to 7.5v, so we have yet another variable, but that's OK since we'll just go with the worst case scenarios.

14. If desat triggers at 6v at Tj=120c, then we need a 4.2 zener to add to the 1.2V from the schotky diode.

15. If desat triggers at 7.5v at Tj=120c, then we need a 5.7V zener added to the 1.2V from the shotky.

16. The question now is where is the MOSFET current at these different zener diode settings. Zeners also only come in a limited number of voltages and they have Reverse break down with <240uA current so we need to make sure to check it's data sheet.

17. We know desat happens as low as 6v, so we'll use that as the spec since we don't want the desat to trigger at a lower than 150A. That meas we need to trigger a 4.2v with just 240uA. We'll go look at the ROHM KDZ series of 1W zeners since they have a graph showing breakdown voltage vs current.

18. Looking at http://rohmfs.rohm.com/en/products/databook/datasheet/discrete/diode/zener/kdz4.3b.pdf we go to the electrical characteristic curves. Here we look at the y axis and see where 240uA falls so we can find the correct zener voltage to order. 240uA is 0.24mA so we go to the 0.01 and then go up one line to 0.02. Looking across we can see if we choose a 4.3v diode only gets us about 2.8V, that's much too low. We'll look at our desired voltage on the X axis. We want 4.3v so we go up until we intersect the zener with the lowest rating at 240uA. Bad news, it looks like we have to use a 5.6v if we are going to use this diode model or we need to go look at other data sheets. We'll just go ahead and use the 5.6v for now until we can bench test it. At 240uA the 5.6v zener looks like it has a reverse break down at 4.5V, so this is the value we will be adding to our 1.2v shottky.

19. Desat pin voltage = 1.2v + Zener + Id * Rds_On so our desat at 6v detection is now 1.2v+4.5*4.14mOhm = 6.32V. 0.32 over our desat, but this can work to our favor since it's good to have the MOSFET have over current set lower as it's running hotter. Our 6v desat thresh hold is now reached at 74A, but remember this is with the MOSFET internals at 125c so it has less capability to handle high current.

20. If we look at the 25C numbers we see the desat triggers at 133A. On startup of a cold morning, our desat current is 175A before we panic and shut down in <5uS. That leaves us an additional 325A overhead until we reach our 500A threshold we determined to be the max current the MOSFET should see under ANY operating condition. Lot's of head room left.

21. Now since we designed for 6.0V desat, we need to check the currents at 7.5V, our other worst case number.

22. Keeping the 5.6v zener which is reversing at 4.5v, The 7.5V the -20c, 25c and +120c over amperage ratings are 1047A, 789A and 436A. These are some big numbers and they exceed our 500A limit for the MOSFET, so what do we do? We need to compromise and choose a higher desat voltage point. We look at the datasheet and we see 6.5V is the typical value. That means the manufacture knows the most common voltage is 6.5, but in some cases it could be 6.0 or 7.5v.

Designing for 6.5V we'll pick a zener reverse voltage using the above spec sheet method and go for 4.8v to reach the 150A limit with the MOSFET at Tj=120C.

-20c, 25c and 120c desat number then become 292a, 218A, 127A. Our worst case scenario numbers for the three temps are as follows

6.0V desat 1A, 1A, 1A <-- this would be painfully obvious during bench testing.

6.5v desat 292A, 218A, 127A

7.5v desat 873A, 656A and 364A <-- this would also be obvious during bench testing, desat would appear not to work

Even with a 1A to 873A variance, the MOSFET would more than likely survive due to it being a very short pulse and the MOSFET having a very high pulse current rating.

This is where a engineering decision needs to be made. How many of these are we building, 1, 10, 100, 10,000? Are we really going to be running at 175c Tj? I hope not, so that buys us more headroom if our application allows the flexibility. If we are only building a low qty such as 10-100 units, then it's going to be more cost effective to setup a simple bench test apparatus and check the desat function by hand with a scope and current sensor, then install the appropriate zener diode to tweak it if required.

Adding all of the extra circuit is over complicating it's function for little benefit. Lots of devices need to be tuned before being released to the public. What's your end goal?

The lower RDSon does make desat a larger challange, but always keep in mind the peak pulse rating of the device for desat purposes. It's capable of handling 1100A for up to 100uS and we only need it to last for <5uS. Less time = less destructive energy.

If you are just designing this additional circuit for the fun and challenge of it, then knock yourself out, but don't engineer something that isn't needed if it's a simple change that can be made during bench testing of the driver (you do plan to bench test and tune the driver don't you?).

This took a while to type out, but I have a project that will most likely use this driver anyways so I had to do this work at some point. I'm using a high RDSon MOSFET so I'm not going to have such giant current swings to worry about, but this was good practice for me anyways.

Another way to handle this situation might be to add a large 1mOhm-5mOhm shunt current sense resistor. This current sense resistor could also act as part of an over current protection circuit per MOSFET group in addition to lowering the range for Desat. What you can get away with depends on the desired power level.