hello everybody, i'm new here and need some help.

i may build an e-bike some day, i'm still only collecting info for now but one big part of it will be to build a 18650 battery pack.

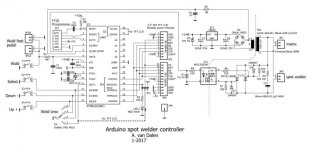

to do this i built a diy spot welder from scavenged parts including a microwave transformer.

but it is working "too well" or not so well in fact : i tend to pierce through the battery shells and nickel strips.

only testing on dead cells but i can't use it untill this problem is fixed

below are some photos of the welder. the problem with scavenged parts i used is i don't really know their caracteristics : the power of the microwave oven or the transformer (except it is 220v 50hz because france), or the gauge of the copper cable i used, .....

i used a timer relay from ebay thinking it would limit the damage but even with it on minimum time, i get sparks and holes.

what did i do wrong ? should i add or remove a turn on the winding and why ?

other ideas? i 'd like to keep it as simple as possible since i lack knowledge in electronics/electricity in general,

any help is welcome. thank you.

pictures :