You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

E-bike + carbon frame + 52V. 18650 + BMC motor

- Thread starter soaresdacosta

- Start date

soaresdacosta

10 kW

My guess is those won't be strong enough. The torque plates will move. There will be a huge amount of force on them.

soaresdacosta

10 kW

fechter,

Thanks for your help. I agreed with your opinion...

This, was just to see if I can cut the metal and do some fabrication on my shop...and I think I can.

This torque plates are full with little cuts and round cuts... not ideal to cut them with "big blue saw".

It will be like the picture, with 2 on each side, with the frame like cheese in a sandwich...

I will secure them with epoxy DP430 from 3M and 2 screws...

Thanks for your help. I agreed with your opinion...

This, was just to see if I can cut the metal and do some fabrication on my shop...and I think I can.

This torque plates are full with little cuts and round cuts... not ideal to cut them with "big blue saw".

It will be like the picture, with 2 on each side, with the frame like cheese in a sandwich...

I will secure them with epoxy DP430 from 3M and 2 screws...

Attachments

soaresdacosta

10 kW

99t4,

Yes, it will.

I will try to install near the old location but... with some changes on the brakes support it will work.

Luís

Yes, it will.

I will try to install near the old location but... with some changes on the brakes support it will work.

Luís

soaresdacosta

10 kW

Hello crew,

Starting this combo for the firme.

Very smoth for a geared motor... not with load but, still...very quiet.

Luís.

Starting this combo for the firme.

Very smoth for a geared motor... not with load but, still...very quiet.

Luís.

soaresdacosta

10 kW

https://youtu.be/yoTcsq7gXu0

Universalus

1 W

Nice bike, but in my opinion, it is not suited for electrification. I would suggest to buy a full suspension bike with old style 9mm QR axle.

To mount a proper torque arms you need to attach them to the frame firmly. Carbon is no-go, especially with through axle.

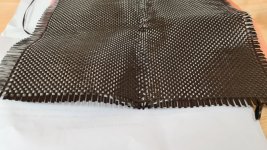

Some examples of my build torque arms:

To mount a proper torque arms you need to attach them to the frame firmly. Carbon is no-go, especially with through axle.

Some examples of my build torque arms:

soaresdacosta

10 kW

Universalus

1 W

Remember, that carbon tube is not designed to be pressed between two metal plates, eventually it will brake.

You still can make a sub 20kg bike using high quality aluminium frame. It is just my recommendation. :thumb:

You still can make a sub 20kg bike using high quality aluminium frame. It is just my recommendation. :thumb:

This is the problem with carbon frames, you need to work with their strengths when attaching things. Need to spread the load out over a large area either through contoured plates or ideally through epoxy. Technically the best way to do this would be to epoxy more carbon fiber and metal parts directly into the frame, with correct surface prep and carbon integration you can build the parts right into the frame with strength like they were built there. The question then is, are you willing to permanently modify the frame?

soaresdacosta

10 kW

Universalus, I will remenber that, when Im doing the torque-arms. Thanks .

scianiac, I will use 3m epoxy and 1 screw on the old axle location. And, yes, I will permanently modify the frame. This will never be a pedal bike, again. Thanks for your ideias.

Luís

scianiac, I will use 3m epoxy and 1 screw on the old axle location. And, yes, I will permanently modify the frame. This will never be a pedal bike, again. Thanks for your ideias.

Luís

Attachments

Sounds like you've got the right idea, you may want to get some carbon fiber fabric or tow and some much thinner layup grade epoxy and wrap and blend that around the mount and frame to add some strength and integrate it into the frame to spread the load out. I'm no composite expert but if it were me I would wrap it in the carbon and epoxy, then a layer of release plastic and then wrap that tightly in something stretchy like an old inner tube cut into strips to compress it all while curing. And of course surface prep, surface prep, surface prep!

Can't wait to see the results, love to see builds that are weight efficient.

Can't wait to see the results, love to see builds that are weight efficient.

soaresdacosta

10 kW

scianiac, thanks for the help and for some good ideias.

I jump in to ebay, and bought some carbon fiber kits... bought some extra to foull around...

We will see...

I jump in to ebay, and bought some carbon fiber kits... bought some extra to foull around...

We will see...

soaresdacosta

10 kW

Hello crew,

Bengy22, thanks for your words.... nice to read.

Decide to change the material on my torque-arms, from stell to alluminium and try to integrate everything with carbon fiber...an ideia from forum member, scianiac .

I already have the carbon fiber kit, but still waiting on the metal....

Luís.

Bengy22, thanks for your words.... nice to read.

Decide to change the material on my torque-arms, from stell to alluminium and try to integrate everything with carbon fiber...an ideia from forum member, scianiac .

I already have the carbon fiber kit, but still waiting on the metal....

Luís.

Attachments

Aluminum is soft. Don't think I'd use it for torque arms.

Kind of a shame to ruin such a nice frame. If you do use it, it would be a good idea to disable regen.

I second the idea of using a quality aluminum frame or maybe an old fashioned steel brazed lug joint road bike frame.

Kind of a shame to ruin such a nice frame. If you do use it, it would be a good idea to disable regen.

I second the idea of using a quality aluminum frame or maybe an old fashioned steel brazed lug joint road bike frame.

Even with a good pinch-bolt clamping design?nicobie said:Aluminum is soft. Don't think I'd use it for torque arms.

Pinch bolt is good, but aluminium is very malleable. I wouldn't trust it, especially if it was on the front wheel.

If you are going to use aluminum torque arms this may be an option. I've considered in the past doing the following. Aluminum makes up the bulk of the torque arm but then insert two flat plates of hardened steel as the clamping surfaces to spread the load out. These could be made from somewhat common tooling that is readily available and inexpensive. Even something as simple as some thick utility blades may be enough although something a tad thicker like may be more suitable. Probably doesn't have to be super hard but you can just look around and find some bits of flat semi-hard steel and epoxy them in to the slots in the aluminum. This all still requires that your torque arm is strong enough to provide suitable clamping force and not deform but that is just a matter of design and is less problematic based on the softness of aluminum. I assume you'll also be using a good grade of aluminum.

soaresdacosta

10 kW

Hello crew,

After play with carbon fiber, one off the kits I bought... I think I will change my mind...again.

If I build some torque plates and integrate them with the frame, using the carbon kit I bought and if they fail or something gone south.... the probability to frock the frame is high... a 3000€ frame...

So... I think I will buy a Crystalite hub motor, a thru axle version with the integrated torque-arm. I will lose the gears, and the torque of the BMC motor, and the light weight... but, I think it's the safest way to go and do not mess with the frame.

If someone as any ideias... please, let me now.

And, if someone as thru axle hub motor for sale in Europe, please send-me a message.

Take care,

Luis.

After play with carbon fiber, one off the kits I bought... I think I will change my mind...again.

If I build some torque plates and integrate them with the frame, using the carbon kit I bought and if they fail or something gone south.... the probability to frock the frame is high... a 3000€ frame...

So... I think I will buy a Crystalite hub motor, a thru axle version with the integrated torque-arm. I will lose the gears, and the torque of the BMC motor, and the light weight... but, I think it's the safest way to go and do not mess with the frame.

If someone as any ideias... please, let me now.

And, if someone as thru axle hub motor for sale in Europe, please send-me a message.

Take care,

Luis.

Attachments

thundercamel

10 kW

I have no experience with these kind of bikes, but what do you think about this? I know you displayed two hub motors, and this is a mid-drive.

[youtube]RvFD0Q909ZY[/youtube]

[youtube]ot8rxRnd2DQ[/youtube]

[youtube]RvFD0Q909ZY[/youtube]

[youtube]ot8rxRnd2DQ[/youtube]

soaresdacosta

10 kW

thundercamel, I like it very mutch.

If I was start another build, this was the way I go... for sure. And the price is ok. At the end, is a very profissional build. If you are considering one, just goooo.

Luis

If I was start another build, this was the way I go... for sure. And the price is ok. At the end, is a very profissional build. If you are considering one, just goooo.

Luis

Bengy22

100 W

- Joined

- Dec 31, 2019

- Messages

- 164

soaresdacosta, I was just thinking of your build thread and checked on it a few days ago, now I see you have posted a update must have knew somehow. I must admit I'm sad to hear you are no longer going to use the geared hub motor. I'm not sure exactly why but geared motors have always intrigued me even though I live somewhere very flat and a hub motor is suited a lot better, and with how much power you were planning to make it have my interests were peaked. But I also understand you don't want to ruin that nice expensive frame you have, just unfortunate you couldn't find a way for that motor to work on that frame. I'm interested to see how the build progresses with the different motor.

I also have seen those videos on the Dengfu frame, really made me want to build a bike with the e22 frame that supports the m620, people that motor with aftermarket controllers pushing 3500w+. Makes me really want to build one but they get $$$ compared to a simple hardtail with a hub motor.

I also have seen those videos on the Dengfu frame, really made me want to build a bike with the e22 frame that supports the m620, people that motor with aftermarket controllers pushing 3500w+. Makes me really want to build one but they get $$$ compared to a simple hardtail with a hub motor.

![Inked20220321_215719[3854]_LI.jpg](/sphere/data/attachments/178/178213-cb790385ab32773f5d46310c1d9223de.jpg)