mxlemming

100 kW

- Joined

- Jul 17, 2020

- Messages

- 1,122

So I want to share some new controllers I have been working on. I am umming and erring about opening the source, since basically no one built my last controller, which works great... If you actually want to build one, perhaps PM me for gerbers.

If you want to DIY a controller, try the MP2/CCC ESC.

This is in some way, a continuation of the original MESC board I made, see:

https://endless-sphere.com/forums/viewtopic.php?f=30&t=107672

GaN board

This board is based on EPC2302 MOSFET, which are probably the best GaN 100V MOS available right now. I am not totally sure of that, but I think so.

They are 5V gate drive, and have incredibly fast switching characteristics, sub 10ns. This presents problems, they simply cannot be used like traditional ES through hole controllers. They have to be laid out absolutely meticulously, with <<1nH inductance in the switching loop (TO-220 has about 7nH, TOLL has about 1nH before considering PCB inductance). The layout below seeks this extreme inductance minimisation, bear in mind there are also uninterrupted power and ground planes on the two inner layers.

The gate drive lines also have to be incredibly low inductance to cope with the high switching speed. I chose to route with differential pairs, using the same board as I use for the IMS. Generally, the appnotes recommend that you place the gate driver right next to the MOS, and minimise the gate inductance to extreme levels... I had a hunch this was not necessary. Calculation of the approximate inductance, capacitance and resistance (4.7 ohm) of the gate/trace showed the damping factor to be high and the resonant frequency away from the switching speeds.

The gate driver needs to be slightly special, work with 5V gate drive and have extreme switching speeds and matching. I used 2EDF7275F for this, an isolated SOIC16 part with low tens of nanosecond delay and matching, and high drive ability. This is not explicitly a GaN driver, is 5x the size of intentional GaN drivers and it is not mentioned atall in the datasheet, instead referring to logic level MOS. Again, I had a hunch this was OK, and wanted to use the same drive board for my IMS power stage.

Obviously (or perhaps not?) you cannot run a GaN stage with low side current sensing, so I added a hall effect phase current sensor, a Chinese copy of the Allegro ACS71x, for 20A and shunted them with a 1mohm resistor to increase the range. I highly recommend not buying these Chinese copies, the noise floor is huge, about 1A on a 20A sensor, but Allegro have decided not to sell to us for now, so what you gonna do...

View attachment 1

Building it was surprisingly easy. I was fully prepared for an absolute battle with the cursed footprint, but a bit of flux, paste (manually applied with a scalpel) and hot air and they just floated into place, with lovely clear solder bumps on the wettable flank. Crazy easy compared to my expectation.

I ran it up to 40A (that's the limit of the current sensor with shunt before hardware overcurrent trips) and all was good. Interestingly, with this layout, there was absolutely no difference between the switching at 1A and 40A. I realise I am hampered by a 100MHz scope with 1GSPS. There may be higher frequency nastiness I cannot see.

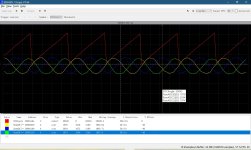

I ran it up to 120kHz FOC switching (VESC speak, the PWM and PID loops are at 60kHz, with the V7 update interpolated)

Sensorless works really nicely. The small dead time (I ran about 150ns, and could have gone much lower) means that there is much less abheration and so sensorless tracking works down to significantly lower frequency.

All in all, pleased to have made the first GaN stage documented on ES. It is snowing and raining constantly, so don;t expect this on my bike any time soon unfortunately

If you want to DIY a controller, try the MP2/CCC ESC.

This is in some way, a continuation of the original MESC board I made, see:

https://endless-sphere.com/forums/viewtopic.php?f=30&t=107672

GaN board

This board is based on EPC2302 MOSFET, which are probably the best GaN 100V MOS available right now. I am not totally sure of that, but I think so.

They are 5V gate drive, and have incredibly fast switching characteristics, sub 10ns. This presents problems, they simply cannot be used like traditional ES through hole controllers. They have to be laid out absolutely meticulously, with <<1nH inductance in the switching loop (TO-220 has about 7nH, TOLL has about 1nH before considering PCB inductance). The layout below seeks this extreme inductance minimisation, bear in mind there are also uninterrupted power and ground planes on the two inner layers.

The gate drive lines also have to be incredibly low inductance to cope with the high switching speed. I chose to route with differential pairs, using the same board as I use for the IMS. Generally, the appnotes recommend that you place the gate driver right next to the MOS, and minimise the gate inductance to extreme levels... I had a hunch this was not necessary. Calculation of the approximate inductance, capacitance and resistance (4.7 ohm) of the gate/trace showed the damping factor to be high and the resonant frequency away from the switching speeds.

The gate driver needs to be slightly special, work with 5V gate drive and have extreme switching speeds and matching. I used 2EDF7275F for this, an isolated SOIC16 part with low tens of nanosecond delay and matching, and high drive ability. This is not explicitly a GaN driver, is 5x the size of intentional GaN drivers and it is not mentioned atall in the datasheet, instead referring to logic level MOS. Again, I had a hunch this was OK, and wanted to use the same drive board for my IMS power stage.

Obviously (or perhaps not?) you cannot run a GaN stage with low side current sensing, so I added a hall effect phase current sensor, a Chinese copy of the Allegro ACS71x, for 20A and shunted them with a 1mohm resistor to increase the range. I highly recommend not buying these Chinese copies, the noise floor is huge, about 1A on a 20A sensor, but Allegro have decided not to sell to us for now, so what you gonna do...

View attachment 1

Building it was surprisingly easy. I was fully prepared for an absolute battle with the cursed footprint, but a bit of flux, paste (manually applied with a scalpel) and hot air and they just floated into place, with lovely clear solder bumps on the wettable flank. Crazy easy compared to my expectation.

I ran it up to 40A (that's the limit of the current sensor with shunt before hardware overcurrent trips) and all was good. Interestingly, with this layout, there was absolutely no difference between the switching at 1A and 40A. I realise I am hampered by a 100MHz scope with 1GSPS. There may be higher frequency nastiness I cannot see.

I ran it up to 120kHz FOC switching (VESC speak, the PWM and PID loops are at 60kHz, with the V7 update interpolated)

Sensorless works really nicely. The small dead time (I ran about 150ns, and could have gone much lower) means that there is much less abheration and so sensorless tracking works down to significantly lower frequency.

All in all, pleased to have made the first GaN stage documented on ES. It is snowing and raining constantly, so don;t expect this on my bike any time soon unfortunately