I ask this because a stator with WYE is inductance in series. But delta is in parallel to 2x the inductance of one phase.Miles said:Yes, Wye termination.

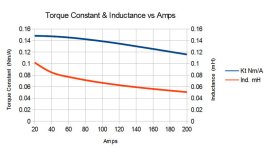

I presume so. You get different values as you vary the load........

Also the motors I measured the stator on the bench out of the magnet ring were about 2x what they were once in the magnetic field.

![BH_iron[1].png BH_iron[1].png](https://endless-sphere.com/sphere/data/attachments/70/70322-a91e9ba382307415f1ba866e377fad2f.jpg)