Learn something new every day ! ! !

Greenpower racing looks like fun, I had no idea it existed.

Have you heard of

Electrathon racing ?

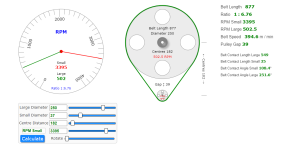

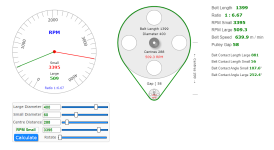

re : gearing . . . most of the human powered speed bikes will multiply the RPM with a secondary shaft.

View attachment 349607

View attachment 349608

In your case the RPM needs to be divided but the same approach can be used.

Typically the secondary shaft is created from a repurposed bicycle freehub body as shown in photo.

Example shown in speed bike photo is from a BMX source but a road bike derailleur style like shown below might add some gear range.

View attachment 349611

The following picture shows an example of a bike with a secondary shaft and dual derailleurs.

The bike is a 35 speed sporting a extra low gear for climbing and extra high gear for speed.

View attachment 349610

Is there any efficiency loss with this scheme ?

With only 2 more bearings in the system it will be low.

Also, on the speed racer bike, the bearings are replaced with high quality ceramic bearings with dust shields ( rubber contact seals are removed )