kfong

100 kW

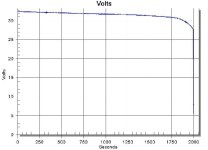

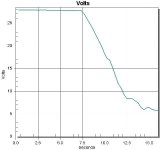

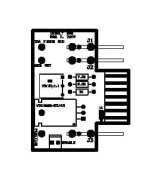

I just finished making boards for the dewalt packs so you can use them without taking them apart. I thought I should post a new thread on it here. These packs have a 3 year warranty and as long as you stay under 20amp per pack you should have no problem using them for ebikes, they should last just as long as if they were used on power tools. I recommend using 3 or more packs in parallel so you can share the current load. With 3 packs you have 60amps available. I'm using 6 packs for a total of 120 amps. The best part is I can still use them for my power tools and misc. uses. The BMS automatically shuts down to protect the packs when they go below 27-28volts. Here are pictures of the boards. I will be selling the bare boards for $5 a piece .5" spacer will be included. PM me if interested

Here is the partlist. You can purchase the rest of the parts from Digikey

(1) 7.7k 1/4watt resistor 7.15k can be substituted since digikey has a minimum order of 5 resistors. cat# 7.15KXBK-ND

(1) 8.5k 1/4watt resistor 7.15k can be substituted

(1) 1k 1/4watt resistor 1.00KXBK-ND

(1) V30100S-E3/45 DIODE SCHOTTKY 30A 100V TO-220AB Digi-Key Part Number V30100S-E3/4WGI-ND

(3) Keystone Electronics quickfit male #1265 Digi-Key Part Number 1265K-ND

The rest is just wiring to your motor controller. Just use the NEG FET and POSITIVE output for power and parallel packs for current. 3 packs should cover most ebikes using hard accelleration. That's 60amp * 32Volts = 1920 watts

Update 1/14/2010: I've decided to sell finished boards for $35. This will be the bare board stuffed with parts and the power tabs soldered onto them. The tabs will be milled on my my cnc so no filing will be needed. I will also glue the bottom spacer so it's a snug fit when plugged into the battery pack.

Note: the boards will work with the 28volt packs as well as the 36volt packs. What was interesting is the 28volt packs had a higher current output of 25amps. I'm guessing it's to make up for the lower voltage.

There have been reports of users losing a pack with the interface boards plugged in now that winter has come. This is due to the older bms circuit not going into sleep mode properly. I don't recommend leaving the packs plugged into the interface board for long periods. Especially, after a full discharge. I usually plug them back into the charger after a ride so it's not something I had to be concerned with. When the battery gets plugged into the interface board, it enables the internal BMS of the Dewalt packs. This is a small processor that requires power to run. That power even though small is still enough to drain the pack. The newer ones go into sleep mode using only minimal current. So it's best not to chance it and just get into the habit of charging the packs after a ride so it's ready for use. Unlike other cell technology these can take a charge anytime, they don't need to be fully cycled.

An inductor will still be needed on most setups http://www.endless-sphere.com/forums/viewtopic.php?f=14&t=10986&start=15 Cost $5

A set of 3 milled connectors would be $2 if you don't wish to file them. 3 needed per board.

Shipping cost is $5, international $7. Contact me at kinf@embeddedtronics.com

Here is the partlist. You can purchase the rest of the parts from Digikey

(1) 7.7k 1/4watt resistor 7.15k can be substituted since digikey has a minimum order of 5 resistors. cat# 7.15KXBK-ND

(1) 8.5k 1/4watt resistor 7.15k can be substituted

(1) 1k 1/4watt resistor 1.00KXBK-ND

(1) V30100S-E3/45 DIODE SCHOTTKY 30A 100V TO-220AB Digi-Key Part Number V30100S-E3/4WGI-ND

(3) Keystone Electronics quickfit male #1265 Digi-Key Part Number 1265K-ND

The rest is just wiring to your motor controller. Just use the NEG FET and POSITIVE output for power and parallel packs for current. 3 packs should cover most ebikes using hard accelleration. That's 60amp * 32Volts = 1920 watts

Update 1/14/2010: I've decided to sell finished boards for $35. This will be the bare board stuffed with parts and the power tabs soldered onto them. The tabs will be milled on my my cnc so no filing will be needed. I will also glue the bottom spacer so it's a snug fit when plugged into the battery pack.

Note: the boards will work with the 28volt packs as well as the 36volt packs. What was interesting is the 28volt packs had a higher current output of 25amps. I'm guessing it's to make up for the lower voltage.

There have been reports of users losing a pack with the interface boards plugged in now that winter has come. This is due to the older bms circuit not going into sleep mode properly. I don't recommend leaving the packs plugged into the interface board for long periods. Especially, after a full discharge. I usually plug them back into the charger after a ride so it's not something I had to be concerned with. When the battery gets plugged into the interface board, it enables the internal BMS of the Dewalt packs. This is a small processor that requires power to run. That power even though small is still enough to drain the pack. The newer ones go into sleep mode using only minimal current. So it's best not to chance it and just get into the habit of charging the packs after a ride so it's ready for use. Unlike other cell technology these can take a charge anytime, they don't need to be fully cycled.

An inductor will still be needed on most setups http://www.endless-sphere.com/forums/viewtopic.php?f=14&t=10986&start=15 Cost $5

A set of 3 milled connectors would be $2 if you don't wish to file them. 3 needed per board.

Shipping cost is $5, international $7. Contact me at kinf@embeddedtronics.com