anth_85

10 mW

This is a write up of the project I have just completed.

I first started using 18650 lithium cells in flash lights on my bicycle for commuting over winter. I then read about how you can get good quality cells out of laptops, and that went on to buying lights and phone charging power banks all ran off the 18650s I had been collecting. I work in IT so get access to quite a few laptops before they go out for recycling. Around December time I counted up and had about 160 of these cells so started to think what I could do with them. Obviously I didn't need them all for lights and charging mobile phones in my caravan, (I camp off grid at dog shows so rely completely on batteries).

I had the idea of putting them together to create a case that anyone can plug stuff into to use at the caravan, AND for it to be lighter and have a bigger capacity than a 110 amp lead acid leisure battery (of which I already have 2).

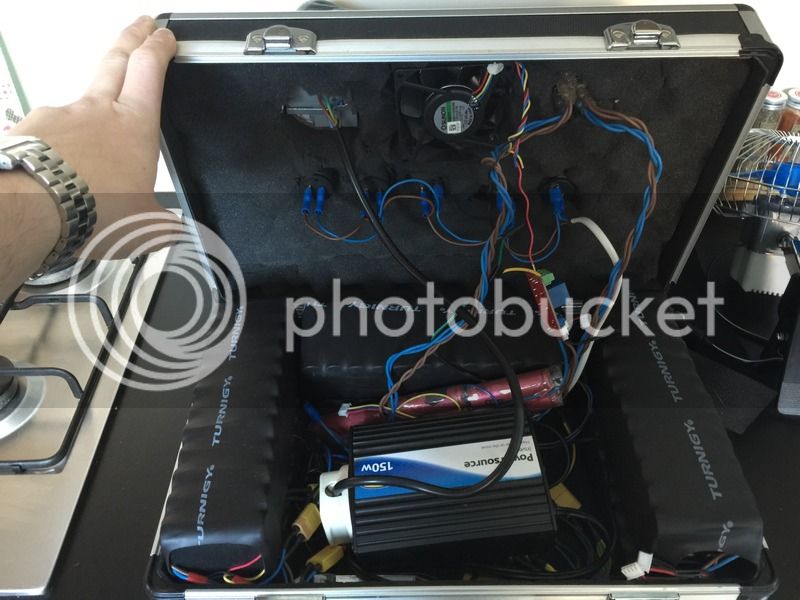

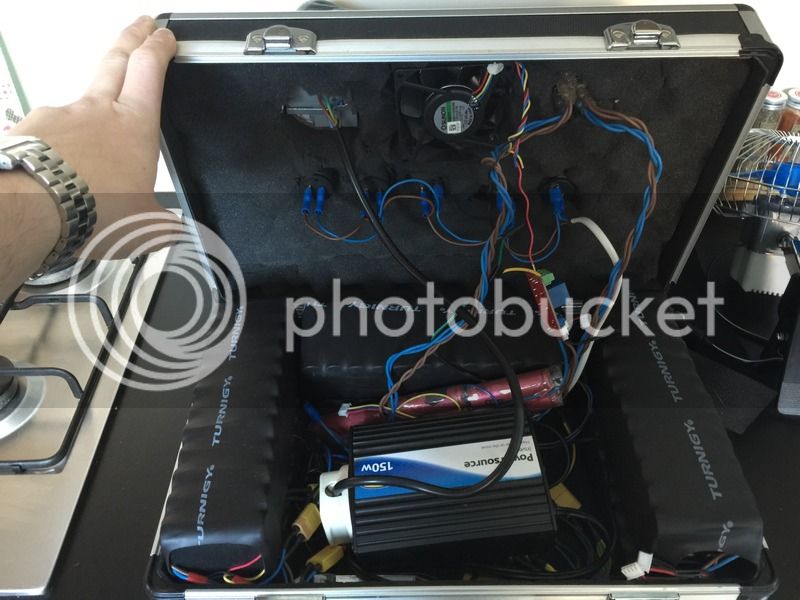

I started to put them together in packs of 36 cells. Running in 3 serial and 12 parallel. I wrapped them in shrink wrap and put balance charge leads and xt60 plugs on them, the same way a RC car etc would, just on a larger capacity.

I have now made 6 of these. I have tested all the cells in them by charging them then leaving them for a couple of weeks then checking their voltage any drop from 4.2 to below 4.1v and they were discarded.

Cells do have a range of makes and models which is to be expected from where I sourced them for free. So I have guessed roughly on average of 2amp per cell, some will be more, some will be less, gives me a rough capacity of 144amps

I have 2 BMS 1 per set of 3 packs, I am planning on increasing this to 1 each, but this is a budget project. They are not plugged into the balance charge leads because I will be charging through my skyrc b6 mini they are only there to protect from over discharge.

I have installed 3 12v car plugs and 4 USB charge plugs.

I have also installed, a 150w inverter than I had spare and ran this to a plug on the outside to make it user friendly.

There are 2 switches on the front, 1 for the main on off for the unit, and another for the inverter, I don't want the inverter running all the time as it has a fan and wastes power when not in use.

I did some research and some people doing similar things were concerned about temperatures. So I have installed a 80mm computer fan, and a temperature controlled relay to automatically turn this on around 22C. I have also installed another temperature sensor with display on the top so I can keep an eye on it, both have their probes between packs. Finally there is a voltage display to I know the state of charge.

Internally my concern was amp draw for cable overheating. So a lot of the cabling has been doubled up. It is standard 13amp mains cabling so 26amp should be sufficient for now. The XT60 connectors are rated at 60amp. Both of these are higher than the BMS will allow before they cut off.

It will be use for the first time this weekend as it is my first weekend away in the caravan so I will see how well it performs. My aim is to not have to worry about the caravan lights and waterpump, the two leisure batteries can easily handle that. This case is going to keep our laptops, phones and tablets charged, run the beer fridge for the BBQ on Saturday and hopefully the projector (yes you read that correctly I have a projector in the caravan).

My original target was a something user friendly, lighter and larger capacity than a 110amp lead acid leisure battery. It is certainly more user friendly, you just plug in what you need. I haven't weighed it yet but I think it is around 15-17kg so it probably just over half the weight of a leisure battery and it should have a larger capacity.

Future plans, I have got another 40 cells so far so the next pack I make up will have larger copper plate connections and thicker wiring and probably xt90 connections. Eventually all packs will be migrated to that with some high gauge cable and some form of connector that I can plug into a 1500 or 2000w inverter so my other half can run her hair dryer off it, that is still quite a way off though and I have a few problems to work round for that.

I have read all about the risks of using lithium and I am aware it does look a little like a bomb :? If anyone has any thoughts of where I could improve the design or any input in general it is appreciated.

I first started using 18650 lithium cells in flash lights on my bicycle for commuting over winter. I then read about how you can get good quality cells out of laptops, and that went on to buying lights and phone charging power banks all ran off the 18650s I had been collecting. I work in IT so get access to quite a few laptops before they go out for recycling. Around December time I counted up and had about 160 of these cells so started to think what I could do with them. Obviously I didn't need them all for lights and charging mobile phones in my caravan, (I camp off grid at dog shows so rely completely on batteries).

I had the idea of putting them together to create a case that anyone can plug stuff into to use at the caravan, AND for it to be lighter and have a bigger capacity than a 110 amp lead acid leisure battery (of which I already have 2).

I started to put them together in packs of 36 cells. Running in 3 serial and 12 parallel. I wrapped them in shrink wrap and put balance charge leads and xt60 plugs on them, the same way a RC car etc would, just on a larger capacity.

I have now made 6 of these. I have tested all the cells in them by charging them then leaving them for a couple of weeks then checking their voltage any drop from 4.2 to below 4.1v and they were discarded.

Cells do have a range of makes and models which is to be expected from where I sourced them for free. So I have guessed roughly on average of 2amp per cell, some will be more, some will be less, gives me a rough capacity of 144amps

I have 2 BMS 1 per set of 3 packs, I am planning on increasing this to 1 each, but this is a budget project. They are not plugged into the balance charge leads because I will be charging through my skyrc b6 mini they are only there to protect from over discharge.

I have installed 3 12v car plugs and 4 USB charge plugs.

I have also installed, a 150w inverter than I had spare and ran this to a plug on the outside to make it user friendly.

There are 2 switches on the front, 1 for the main on off for the unit, and another for the inverter, I don't want the inverter running all the time as it has a fan and wastes power when not in use.

I did some research and some people doing similar things were concerned about temperatures. So I have installed a 80mm computer fan, and a temperature controlled relay to automatically turn this on around 22C. I have also installed another temperature sensor with display on the top so I can keep an eye on it, both have their probes between packs. Finally there is a voltage display to I know the state of charge.

Internally my concern was amp draw for cable overheating. So a lot of the cabling has been doubled up. It is standard 13amp mains cabling so 26amp should be sufficient for now. The XT60 connectors are rated at 60amp. Both of these are higher than the BMS will allow before they cut off.

It will be use for the first time this weekend as it is my first weekend away in the caravan so I will see how well it performs. My aim is to not have to worry about the caravan lights and waterpump, the two leisure batteries can easily handle that. This case is going to keep our laptops, phones and tablets charged, run the beer fridge for the BBQ on Saturday and hopefully the projector (yes you read that correctly I have a projector in the caravan).

My original target was a something user friendly, lighter and larger capacity than a 110amp lead acid leisure battery. It is certainly more user friendly, you just plug in what you need. I haven't weighed it yet but I think it is around 15-17kg so it probably just over half the weight of a leisure battery and it should have a larger capacity.

Future plans, I have got another 40 cells so far so the next pack I make up will have larger copper plate connections and thicker wiring and probably xt90 connections. Eventually all packs will be migrated to that with some high gauge cable and some form of connector that I can plug into a 1500 or 2000w inverter so my other half can run her hair dryer off it, that is still quite a way off though and I have a few problems to work round for that.

I have read all about the risks of using lithium and I am aware it does look a little like a bomb :? If anyone has any thoughts of where I could improve the design or any input in general it is appreciated.