If not its own BMS, you would need a harness that serves every packs cells, and yes this is called a " pigtail"....

Pigtail parallel charging is frowned upon int he hobby RC community just because of the truth in your statement ...

Really comes down to this: Certainly. People have done it, but yeah you are right there. Just for that reason. You cannot assure a balance with pigtail charging. On another thread, going over this with another ES poster: He mentioned this:

-Charging them with a single charger runs the hazard of over charging the lower capacity one

Having a BMS for every pack is a logistic nightmare, as is balance charging every pack individually.

SafeDiscDancing wrote: ↑

Mar 03 2022 11:17pm

So if you have two series strings which you then combine as parallel "afterwards" then the weakest cell will exist "somewhere" in one of those two series strings.

... the RATE at which the weakest cell either needs more energy or wants less of it will increase as the cell gets worse and worse.

Most ...

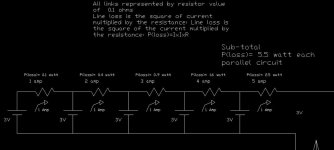

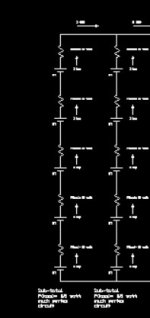

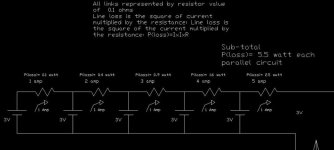

A friend of mine once layed it out for me on paper like this: Look at the diagram and you can see how the line resistance changes with each setu... Now, a healthy battery wont have problems, but a battery with IR resistance and connection resistance all over the place will suffer from wasted energy, short life, and detriment.

Now this example is exaggerated ( you dont lose amps per connection, but milliamps maybe, 1/1000 of an amp, in practice) for showing the point. Imagine: The numbers getting worse, here or there, over time, connection building resistance, not taking charge well, never filling and never balancing because of tiny variation int eh design of the current path. Causing detriment over time. Eventually you have a " heater" weak cell that takes and wastes heat on discharge and recharge, goes out of balance, and takes more energy to charge cause its collumbic efficiency is getting worse and worse... How this bad cell affects the pack, either type of battery, is shown below. This is just diagramming the line loss and you can imagine the difference if one number here or there goes fluke.

I personally think the top example is better, with the 5 (5s) packs in parallel each with a 1p, then paralleled), that the bottom pic, showing the typical way an nickel ebike pack is built ( with many p in groups). But this ( the way I like) is not the way many build the packs. It is generally accepted that it is better to have all the pack make up or many p for a single set in the total string. Have them all leveled and balancing themselves.. ie, parallel first, series second. The ideal behind this is larger application, larger cell, and you need less ( I use one cell for 25Ah, not (10) 2.5Ah cells) ( little cells are for flashlights in y opinion). The cells stay in balance in the set, you dont need a physical balance wire to service every cell ( and a bunch of wires that need protection, and physical design constraint). Like SDD said above, the weakest cell IS gonna exist somewhere...

Now this works great if you have a lot of money that you can replace packs, but, even the Chevy Volt HV battery parallels its two cells first then strings them along... I guess it is alot easier to do 96s2p, in one battery, rather than two 96s1p packs in parallel. Alot of modern EV are like this... and managed by very * fancy * BMS.... one 290v module.

Top would be like if you get five HobbyKing lipos and string them along in parallel.. Bottom is is you parallel 5p first then string the five parallel groups along for the 15v of the 5s ( easily battery murdere.. er... managing system installed) like most ebike packs. Losses are exaggerated.

Some of it is packaging convenience, some is electrical constraints. Whats more important to you. Design constraint is always a tradeoff. For your intended application.