speedmd

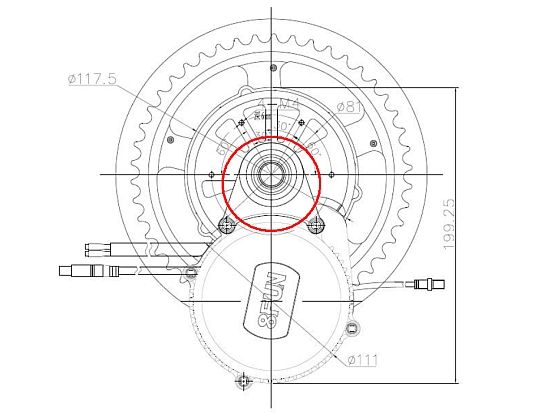

10 MW

I'm gonna run mine with a 18fet lyen controller till something breaks.

Something like this will be a game changer on this kit. 3-5 KW for a few seconds will certainly find the weak spots and when fixed a whole new day for the BBS system.

Start shopping for a shop to machine some bronze gears to replace those plastic ones. :lol: I will want a set also.