Old thread, but I figured my experience might help someone.

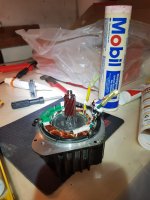

I have a 750W Bafang I purchased in 2018 on my cargo bike. After just 600 km I started hearing rattling inside the bottom bracket when pedaling hard or when the electric motor kicks in. My assumption was that water and dirt got in when riding on muddy autumn roads. As spring is coming I started the rebuild.

First I ordered new SKF needle bearings.

Second I took apart the bottom bracket. Contrary to Philip's description the aluminium nut on the left side can stay on the bike. Also instead of buying special tooling for undoing the nuts with 4-slots I just used 2 pairs of bent pliers (

https://images-na.ssl-images-amazon.com/images/I/610+VDY3oAL._SX425_.jpg) and a helping hand on the other side to keep the axle from turning. What I found inside was actually a pleasing site. Everything seemed well lubricated and clean. The only thing immediately wrong was that one of the push-bearings was missing one ball:

Thirdly I just cleaned everything and relubricated. As I didn't have replacement for push bearing then I kept the left side withut one ball. With the reassembly I could notice straight away that the crank shaft didn't slide in like it had come out, but had to be pushed while pedaling. After reassembly I went for a short ride and pedaled as hard as I could - couldn't hear any rattling.

My conclusion is that since the new needle bearings were so much tighter then the originals were allowing too much play and the push bearings were taking part of the rotational punishment. But of course this is a quess.

Notes:

1. Like Philip, I would say you can't rebuild with same components as getting needle bearings out will destroy them.

2. The new motors actually have a decent seal and I found no water inside after riding on very dirty roads. Also considering I kept my bike locked on the terasse the whole winter in the rain and snow. This seal seems to be custom with BF writen on it. Dimensions 15,3 x 27 x 3 mm if older model owners want to upgrade.