Hummina Shadeeba

1 MW

Luckily there’s no eddies formed in the motor mount tube

Belts are new to me. I’m a long-time chain bike rider.

It uses a two-way throttle with a mid-drive which seems rare.

I’m hoping to find a two-way throttle that allows more degrees of rotation accelerating instead of the 50/50 split acceleration/brake it has now. Please tell if u have advice.

The bottom bracket flexes when standing on one leg and the belt will move across the big unflagged pulley. It has 2mm extra room to move across the pulley but should’ve made it 4. Couldve gotten the pulley made with flanges but didn’t because of possibly seemingly obsessive goals of better efficiency and less noise and wanting to assure it was aligned and not rely on the pulleys. I rarely ride standing on one leg so likely wont change anything.

Wish I had the frame made longer and would feel more secure at higher speeds…30mph high at least. Wish the bottom bracket was lower.

Wish it had 1 1/8” headtube and I had to have external bearing cups made so can use 1 1/8” fork. Thank god for that possibility and needing a 1” fork is ridiculous. I glued the cups in and were a slide fit.

The saddle is pure full carbon. Pure full stiffness. Ridiculous. One day I’ll probably get something but in this upright position it’s not bad. Kinda nice.

7:1 gear ratio

83100 motor. 69x50 stator. .15mm laminations which is super thin. I swapped the motor’s hub to add big bearings. the shafts that came with it are loose at 11.95mm for ease of assembly I guess and produces annoying vibration noises at 8mph and 12mm shafts in the mail. Retaining fluid, even the thick kind, didn’t work with the out-runner requiring sliding the shaft through both bearing and it rubs off. Also tried using a center punch tool. That does work at holding the shaft in the bearings but it’s a delicate job and I went into it too fast. Should’ve set the center punch to low force and the dents and rises I made on the shaft compressed the bearings and didn’t spin smoothly. The coming shafts are as short as possible but the shaft length as it is here isn’t an obstacle for feet.

Locking bushing is very nice, and solid, and simple.

Gt3 belt is the best these days. Or gates gt4 or whatever. Most torque. Quietest. It is very quiet.

Track rear hub uses an aluminum adapter to fit 144 bcd chainrings. The front chainring is 21 teeth and all-n-all it’s surprisingly quiet. 3/8” chain.

The freewheel just fits the smallest chainring bolt pattern

I can stick my fingers into the motor and touch the windings. It’s very nice to see how things heat up and also see the heat leave very fast. I had planned to add some forced air or water cooling from the seatpost but it stays cool enough.

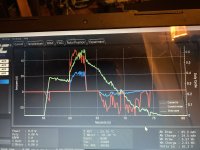

Flipsky 75100 aluminum esc with no limits firmware programmed to 200 motor amps but doesn’t go over 55 and the motor saturates then and only 45kv

24s3p lifepo4 k2 26650 cells. 87v full charge. Potted in 60D polyurethane

Belts are new to me. I’m a long-time chain bike rider.

It uses a two-way throttle with a mid-drive which seems rare.

I’m hoping to find a two-way throttle that allows more degrees of rotation accelerating instead of the 50/50 split acceleration/brake it has now. Please tell if u have advice.

The bottom bracket flexes when standing on one leg and the belt will move across the big unflagged pulley. It has 2mm extra room to move across the pulley but should’ve made it 4. Couldve gotten the pulley made with flanges but didn’t because of possibly seemingly obsessive goals of better efficiency and less noise and wanting to assure it was aligned and not rely on the pulleys. I rarely ride standing on one leg so likely wont change anything.

Wish I had the frame made longer and would feel more secure at higher speeds…30mph high at least. Wish the bottom bracket was lower.

Wish it had 1 1/8” headtube and I had to have external bearing cups made so can use 1 1/8” fork. Thank god for that possibility and needing a 1” fork is ridiculous. I glued the cups in and were a slide fit.

The saddle is pure full carbon. Pure full stiffness. Ridiculous. One day I’ll probably get something but in this upright position it’s not bad. Kinda nice.

7:1 gear ratio

83100 motor. 69x50 stator. .15mm laminations which is super thin. I swapped the motor’s hub to add big bearings. the shafts that came with it are loose at 11.95mm for ease of assembly I guess and produces annoying vibration noises at 8mph and 12mm shafts in the mail. Retaining fluid, even the thick kind, didn’t work with the out-runner requiring sliding the shaft through both bearing and it rubs off. Also tried using a center punch tool. That does work at holding the shaft in the bearings but it’s a delicate job and I went into it too fast. Should’ve set the center punch to low force and the dents and rises I made on the shaft compressed the bearings and didn’t spin smoothly. The coming shafts are as short as possible but the shaft length as it is here isn’t an obstacle for feet.

Locking bushing is very nice, and solid, and simple.

Gt3 belt is the best these days. Or gates gt4 or whatever. Most torque. Quietest. It is very quiet.

Track rear hub uses an aluminum adapter to fit 144 bcd chainrings. The front chainring is 21 teeth and all-n-all it’s surprisingly quiet. 3/8” chain.

The freewheel just fits the smallest chainring bolt pattern

I can stick my fingers into the motor and touch the windings. It’s very nice to see how things heat up and also see the heat leave very fast. I had planned to add some forced air or water cooling from the seatpost but it stays cool enough.

Flipsky 75100 aluminum esc with no limits firmware programmed to 200 motor amps but doesn’t go over 55 and the motor saturates then and only 45kv

24s3p lifepo4 k2 26650 cells. 87v full charge. Potted in 60D polyurethane

Attachments

-

89CA6004-C5F3-4DA5-8E02-1BEB02A07CB9.jpeg1.6 MB · Views: 73

89CA6004-C5F3-4DA5-8E02-1BEB02A07CB9.jpeg1.6 MB · Views: 73 -

image.jpg1.8 MB · Views: 60

image.jpg1.8 MB · Views: 60 -

image.jpg2 MB · Views: 58

image.jpg2 MB · Views: 58 -

B3C1B6C6-E09F-4082-BBB2-2130EDA13FDF.jpeg1.5 MB · Views: 73

B3C1B6C6-E09F-4082-BBB2-2130EDA13FDF.jpeg1.5 MB · Views: 73 -

E4EC7F4C-8F51-461E-87F5-F2EA6F0BAFD6.png4 MB · Views: 95

E4EC7F4C-8F51-461E-87F5-F2EA6F0BAFD6.png4 MB · Views: 95 -

FB3D9B7E-A730-4FF3-9B8F-C607CF197B34.jpeg2.4 MB · Views: 91

FB3D9B7E-A730-4FF3-9B8F-C607CF197B34.jpeg2.4 MB · Views: 91 -

2234CA56-7E9F-4E4D-ABC2-27DD8306969B.jpeg2 MB · Views: 77

2234CA56-7E9F-4E4D-ABC2-27DD8306969B.jpeg2 MB · Views: 77 -

6D7BFAA1-BAE4-4D56-8BF7-ED3B401738FB.jpeg1.6 MB · Views: 58

6D7BFAA1-BAE4-4D56-8BF7-ED3B401738FB.jpeg1.6 MB · Views: 58 -

5AA33133-1CF9-46D5-9F2B-D33FAB24522A.jpeg1.6 MB · Views: 59

5AA33133-1CF9-46D5-9F2B-D33FAB24522A.jpeg1.6 MB · Views: 59 -

4A4BD886-50FA-42F9-86B5-B1A147E73086.jpeg4 MB · Views: 73

4A4BD886-50FA-42F9-86B5-B1A147E73086.jpeg4 MB · Views: 73

Last edited: