pawelr98

1 µW

Hello

I'm new to the forum so I wanted to start with showing my e-bike that I use for daily commute.

Let's start with the specs:

Steel Frame 24" bike from ~2007

MY1016Z 250W 36V brushed DC motor

"Because" freewheel aluminium crank

2x28T schimano gears on crank

11S6P LG MG1(10A 2900mAh) battery- self made

PWM driver based on TL494 and mosfets-self made

Speed:20-25km/h normally, 30-32km/h on flat road with lowest gear ratio and fully charged battery

It all started in early 2016 when I got the idea.

I was in my last year of highschool.

It was at that time when I decided to actually build an ebike.

Later I purchased a stick welder and welded the frame extension(frame of a small children bike was cut into pieces).

Then I could really start using it.

At that point I was using 3x12V 20Ah lead-acid batteries and I didn't have freewheel crank.

Pretty much how it looked like back then.

[youtube] https://www.youtube.com/watch?v=TKPS6F4EImU [/youtube]

I was riding it from time to time to get some parts from hardware store.

Because I had a normal crank I had to ride with legs up.

The shadow casted by the frame and myself looked a bit similar to a person "riding" a broom.

This is where the name comes from.

But most likely you noticed the welded extra pair of pedals.

At the beggining it served two purposes:

-place for legs when riding

-motor activation

The "motor activation" part is because of Polish bicycle law (most EU countries have similar laws).

E-bike can be called a standard bike when following conditions are met:

-250W max nominal motor power -check ("nominal" giving a lot of room for extra power)

-48V max voltage -check

-25km/h max speed -check (mechanical limit based on gear ratio)

-Motor activated by pressure on pedals- check

They really did directly state that there must be "pressure on pedals".

So I did exactly that. There's a simple thyristor circuit which activates the controller when pedals get pushed once.

Later I purchased a freewheel crank which finally allowed me to ride normally.

The worst thing that remained were the lead-acid batteries.

They were just darn heavy. ~20Kg on the frame extension (high center of gravity) made it rather unstable on corners.

I didn't use it much because I was spending my time in a different city attending university.

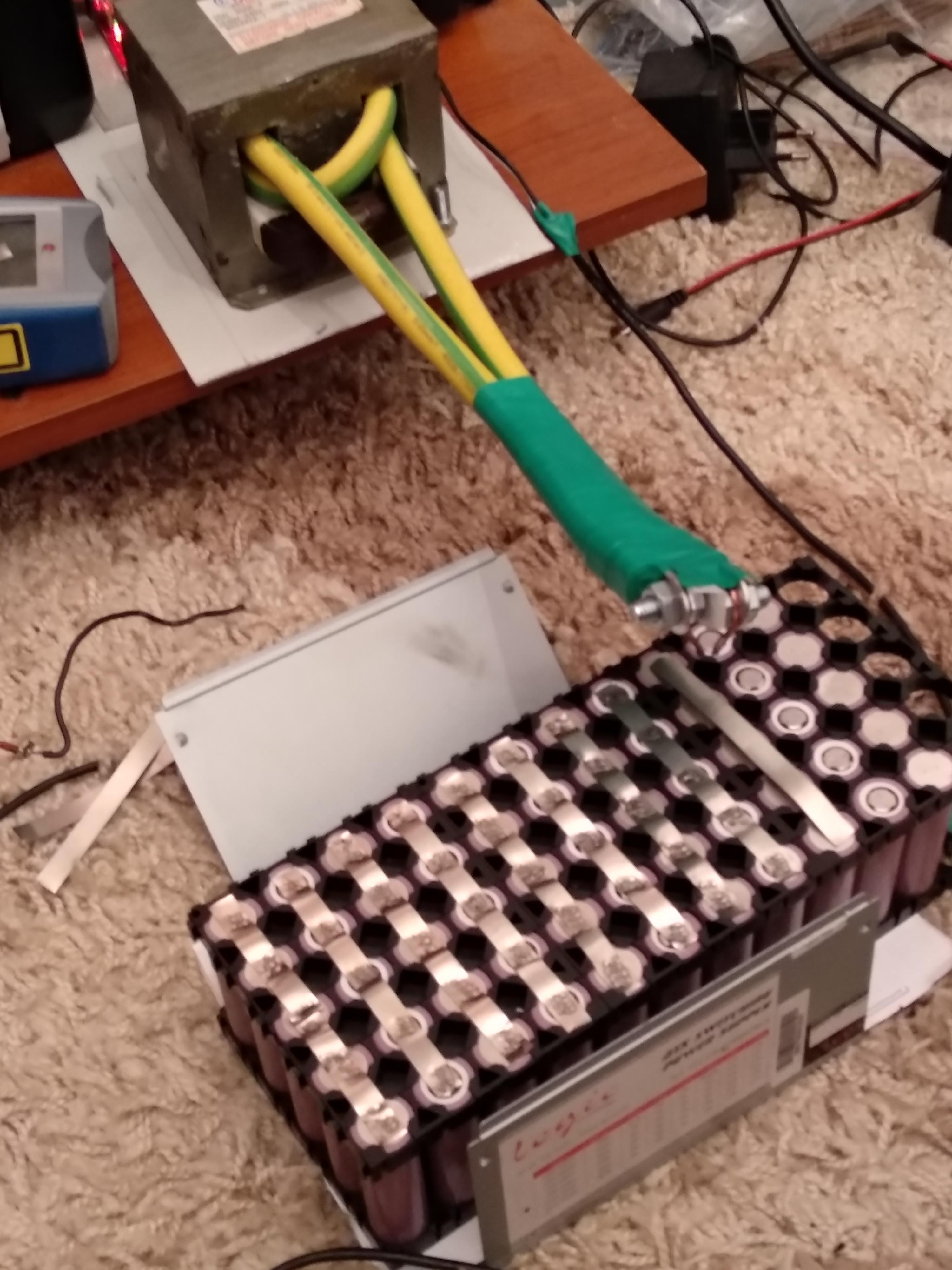

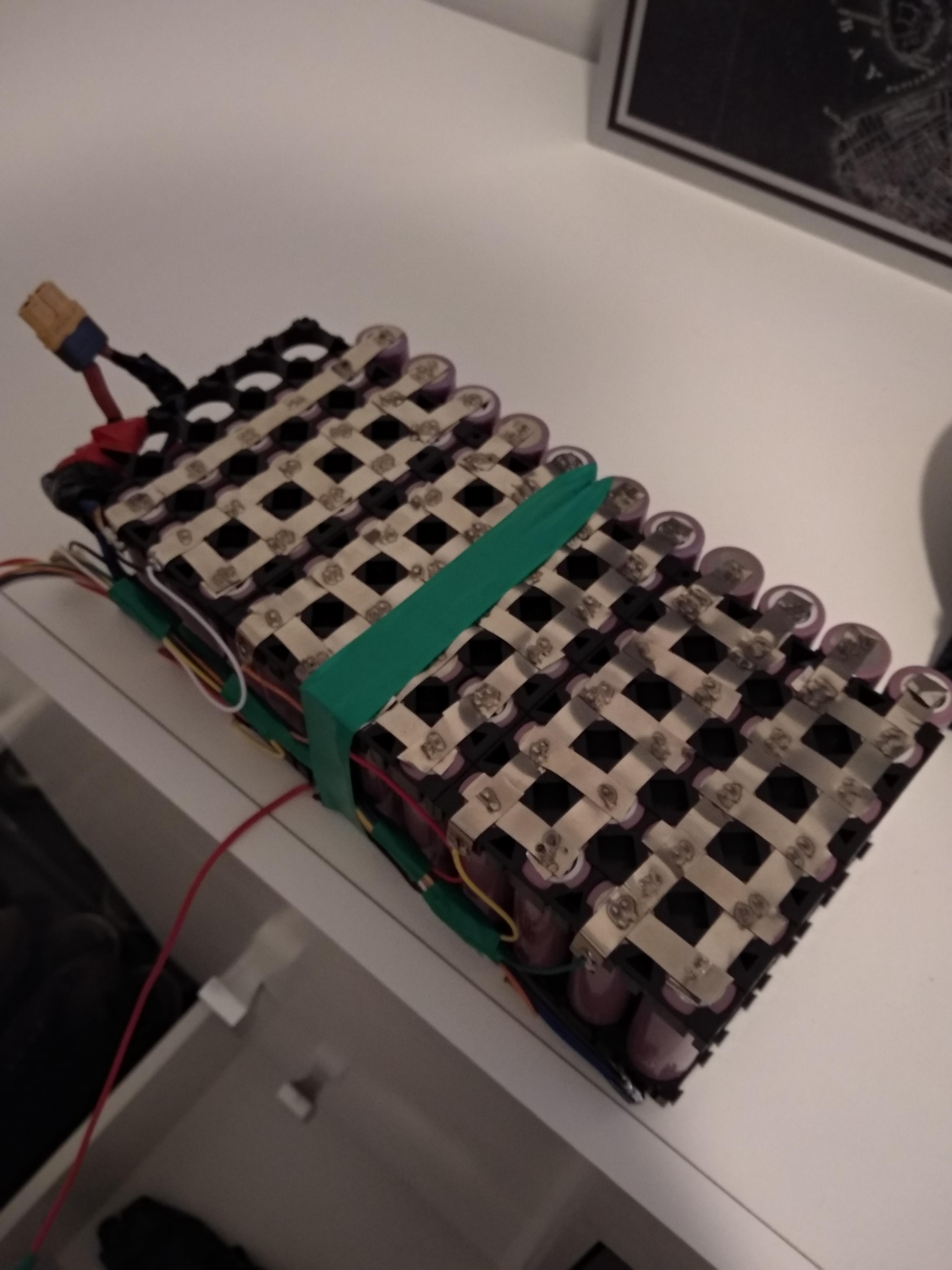

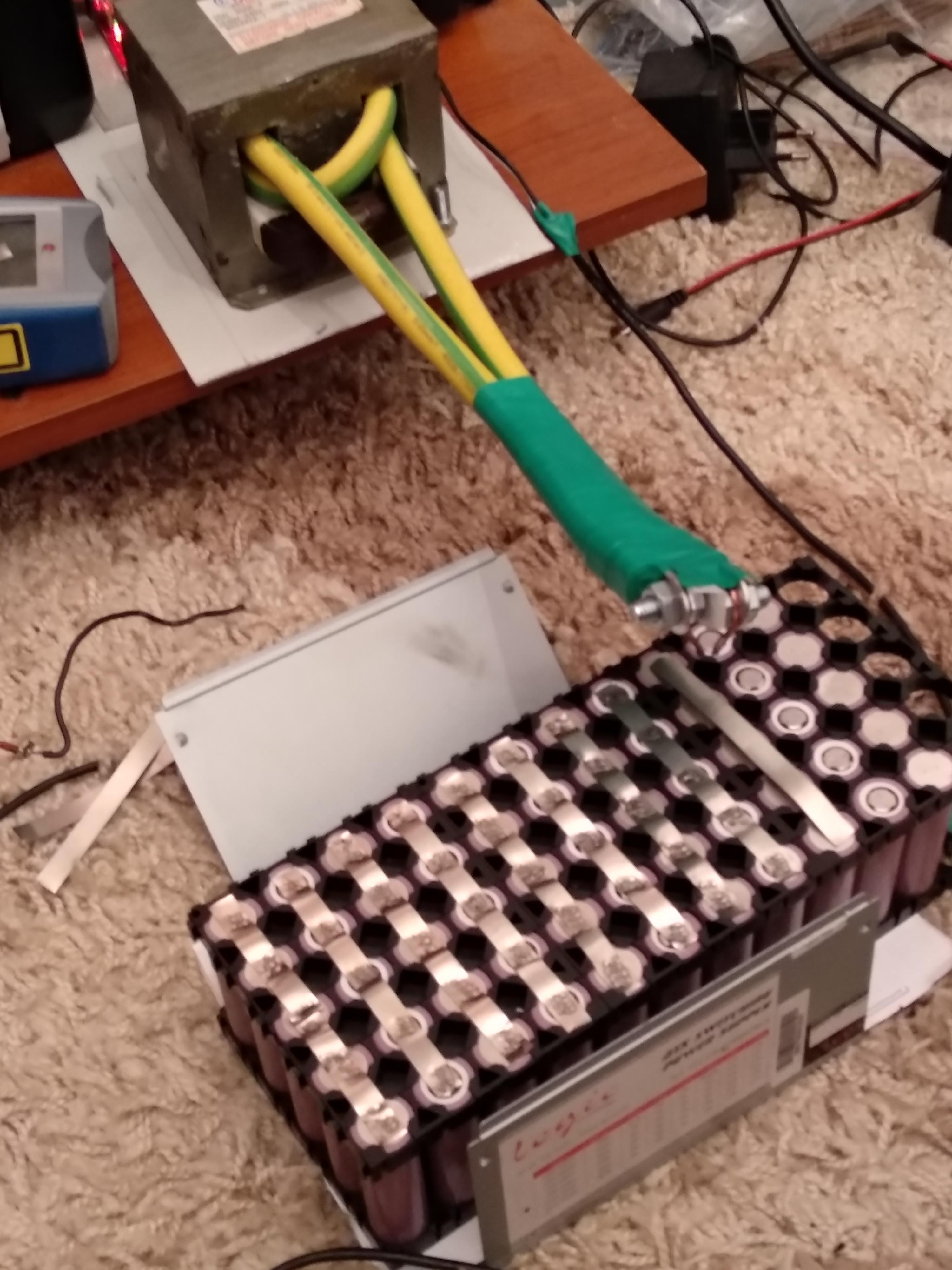

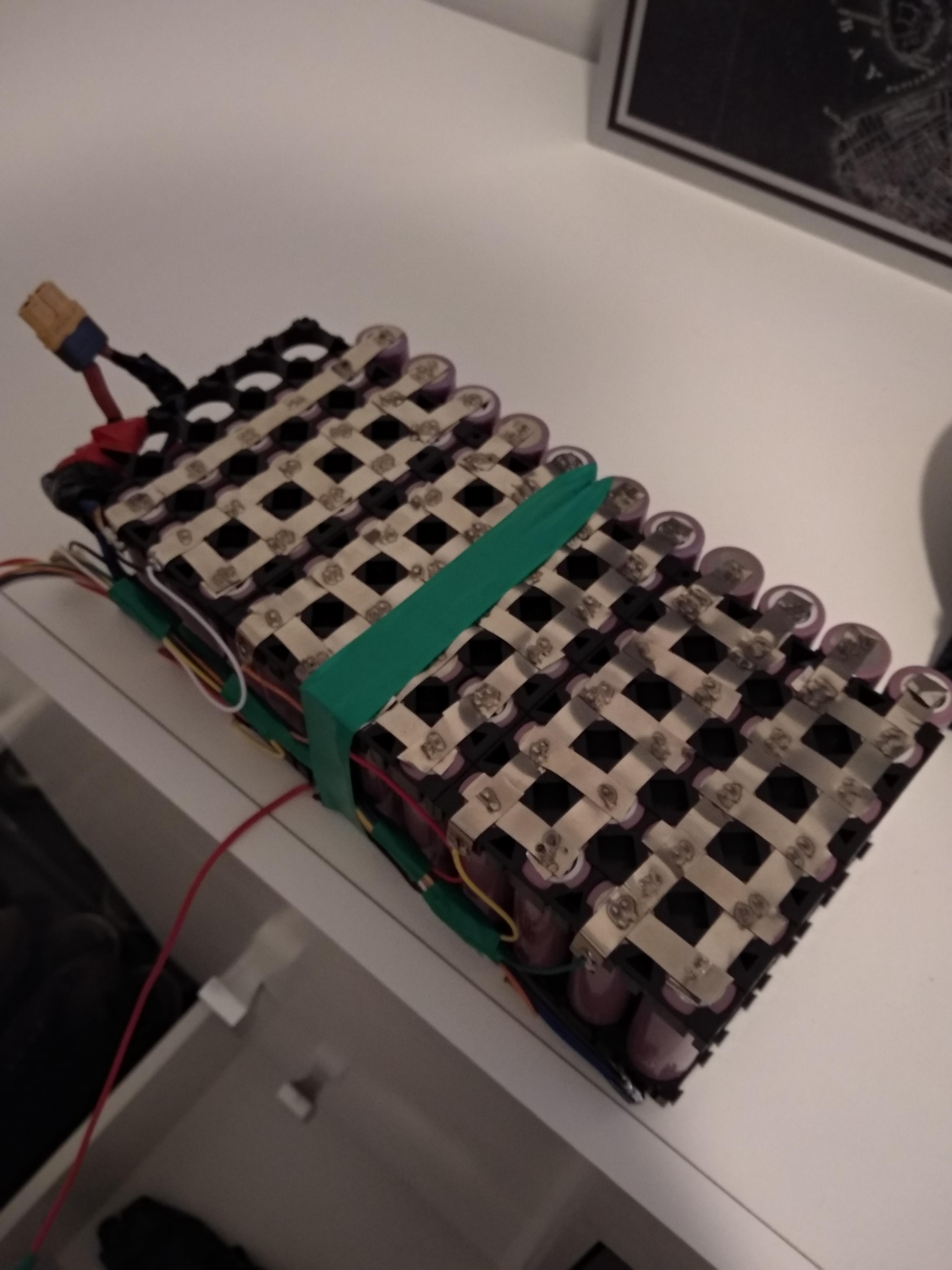

The great breakthrough came when I decided to put together a spot-welder for 18650 cells.

I purchased cheap new LG MG1 cells which had been removed from new batteries.

They measured like a brand new cell.

Battery ended up like this. Balance ports divided it into 6S + 5S for charging with Imax B6.

I don't use any BMS system. Just balance charger.

I monitor the voltage using small voltmeter and the battery is protected from shorts by a 25A fast-blow fuse.

After I made the battery I decided to do some more work on the bike.

Removed some junk parts I welded years ago, aligned the rear wheel, replaced the front brake(only one), added lighting and many other small improvements.

The state of the bicycle as it is today.

Doing commute 2 days in a week because it's faster than public transport in early hours.

Public transport can get really crowded and people can even "fight" for ability to get into a bus.

Really gets attention when I roll into university gate on this thing.

Chinese throttle cracked on my first commute. Had to replace hall-sensor(leads broke off) and tape it back together.

24" wheels are small for my height (181cm) so I just happened to hit the key when getting off the bike.

The throttle went into pieces. Really low quality plastic.

Running fixed gear, at one point I melted the line during welding .

.

Simple protection, a steel rod frame along with a chain and a padlock.

Steel frame is easy to weld using cheap stick welder. Aluminium is not.

If I am to replace the frame then I'm going to get another steel frame.

250W is NOT ENOUGH for rides in "hilly" terrain.

You can kill the motor faster than you think.

I increased the gear reduction to prevent the motor from burning on daily commutes.

I really wish Poland would increase the motor limit to 350W at least(500W would be ideal).

However plenty of e-bike people around here are just using stronger motors which is illegal(such ebike is classified as moped).

Not that police cares much.

Each time the motor struggles I'm considering putting a stronger brushed DC motor or a BLDC motor(a normal one I can just put in the mounting place of current one, it will have better cooling than a hub motor).

Maybe if I kill the current motor then I will really consider purchasing a new stronger one.

For now I prefer sticking to the law.

I'm new to the forum so I wanted to start with showing my e-bike that I use for daily commute.

Let's start with the specs:

Steel Frame 24" bike from ~2007

MY1016Z 250W 36V brushed DC motor

"Because" freewheel aluminium crank

2x28T schimano gears on crank

11S6P LG MG1(10A 2900mAh) battery- self made

PWM driver based on TL494 and mosfets-self made

Speed:20-25km/h normally, 30-32km/h on flat road with lowest gear ratio and fully charged battery

It all started in early 2016 when I got the idea.

I was in my last year of highschool.

It was at that time when I decided to actually build an ebike.

Later I purchased a stick welder and welded the frame extension(frame of a small children bike was cut into pieces).

Then I could really start using it.

At that point I was using 3x12V 20Ah lead-acid batteries and I didn't have freewheel crank.

Pretty much how it looked like back then.

[youtube] https://www.youtube.com/watch?v=TKPS6F4EImU [/youtube]

I was riding it from time to time to get some parts from hardware store.

Because I had a normal crank I had to ride with legs up.

The shadow casted by the frame and myself looked a bit similar to a person "riding" a broom.

This is where the name comes from.

But most likely you noticed the welded extra pair of pedals.

At the beggining it served two purposes:

-place for legs when riding

-motor activation

The "motor activation" part is because of Polish bicycle law (most EU countries have similar laws).

E-bike can be called a standard bike when following conditions are met:

-250W max nominal motor power -check ("nominal" giving a lot of room for extra power)

-48V max voltage -check

-25km/h max speed -check (mechanical limit based on gear ratio)

-Motor activated by pressure on pedals- check

They really did directly state that there must be "pressure on pedals".

So I did exactly that. There's a simple thyristor circuit which activates the controller when pedals get pushed once.

Later I purchased a freewheel crank which finally allowed me to ride normally.

The worst thing that remained were the lead-acid batteries.

They were just darn heavy. ~20Kg on the frame extension (high center of gravity) made it rather unstable on corners.

I didn't use it much because I was spending my time in a different city attending university.

The great breakthrough came when I decided to put together a spot-welder for 18650 cells.

I purchased cheap new LG MG1 cells which had been removed from new batteries.

They measured like a brand new cell.

Battery ended up like this. Balance ports divided it into 6S + 5S for charging with Imax B6.

I don't use any BMS system. Just balance charger.

I monitor the voltage using small voltmeter and the battery is protected from shorts by a 25A fast-blow fuse.

After I made the battery I decided to do some more work on the bike.

Removed some junk parts I welded years ago, aligned the rear wheel, replaced the front brake(only one), added lighting and many other small improvements.

The state of the bicycle as it is today.

Doing commute 2 days in a week because it's faster than public transport in early hours.

Public transport can get really crowded and people can even "fight" for ability to get into a bus.

Really gets attention when I roll into university gate on this thing.

Chinese throttle cracked on my first commute. Had to replace hall-sensor(leads broke off) and tape it back together.

24" wheels are small for my height (181cm) so I just happened to hit the key when getting off the bike.

The throttle went into pieces. Really low quality plastic.

Running fixed gear, at one point I melted the line during welding

Simple protection, a steel rod frame along with a chain and a padlock.

Steel frame is easy to weld using cheap stick welder. Aluminium is not.

If I am to replace the frame then I'm going to get another steel frame.

250W is NOT ENOUGH for rides in "hilly" terrain.

You can kill the motor faster than you think.

I increased the gear reduction to prevent the motor from burning on daily commutes.

I really wish Poland would increase the motor limit to 350W at least(500W would be ideal).

However plenty of e-bike people around here are just using stronger motors which is illegal(such ebike is classified as moped).

Not that police cares much.

Each time the motor struggles I'm considering putting a stronger brushed DC motor or a BLDC motor(a normal one I can just put in the mounting place of current one, it will have better cooling than a hub motor).

Maybe if I kill the current motor then I will really consider purchasing a new stronger one.

For now I prefer sticking to the law.