DudeeBalls

100 mW

- Joined

- Apr 29, 2015

- Messages

- 36

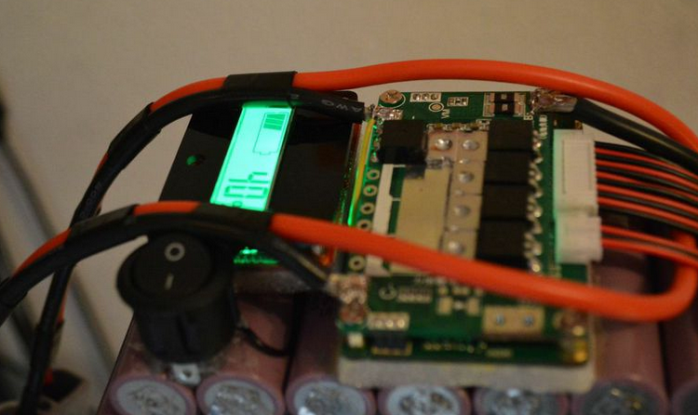

I found the following BMS on ebay and wanted to know what you all think of it. I'm thinking of using the BMS to balance charge my recycled laptop 18650 10s 40ah battery pack in conjunction with some kind of bulk lithium charger while on the go and away from home (got an iCharger 1010B+ for home). I'll probably bypass the BMS for discharging (draining the pack while riding) cause I figure I can't count on it's 30a rating at that price and that it'll serve more as charge protection/balancer for my potentially easily unbalanced pack due to the use of so many batteries from different sources with potentially different capacities and/or internal resistances. I'm almost out of money with all the recent investments in my electric bike project so if anyone could recommend a 10s bulk lithium charger to use with this BMS that won't cost me as much as the charger or more for shipping and does at least 5a (so it won't take more than 10 hours to charge my 40ah pack) it would be much appreciated. I've heard stuff from meanwell mentioned but I don't know much about that and there's a new 10s 36v6a one from BMSBattery called the S240 but it cost $73.39 after shipping ($30 before) and ebay only has one listed that's aluminum 10s and 5a but it cost around $83 after shipping. Both of which would be no biggy if I hadn't already broken the bank on the iCharger and the special balance cables for it (which cost a lot in and of themselves).

In case anyone is wondering why I made a 10s24p battery (240-18650's) it's not cause I intend on going to the moon and back without refueling it's because I bought them like that from some guy on craigslist who gave up on his own ebike project after making it. I'm gonna break it up (cut the tabs between each 24-pack and untape/uncardboard them from one another) into 10 24p groups so I can put a balance lead on each set then maybe I'll put cardboard and tape around each pack and connect them in series with wires/connectors so if one goes seriously wrong it won't damage the others as much, they can be traded out easier etc. I don't trust just charging it as is without balance leads cause I don't really know much about what testing the guy did prior to connecting it all (it measures 35 point something volts as it came). For some odd reason one of the packs of 24 has rust all over the top of it including on the solder tabs as if battery acid poured all over it after it was all soldered together but I haven't found the source yet so perhaps some had burst and he removed them. I had someone pick the cells up for me out of town and the guy who sold them was Chinese I think and spoke very poor English so I wasn't able to understand any of his answers but for $100 for what looks to be around 405 18650's I think it's a pretty sweet deal. He even threw in a few sets of flatish small cellphone looking batteries strung/taped together that I think may have been from some kind of old/oddschool laptops and some of the laptop packs aren't even hacked open yet but I included them in my total estimate.

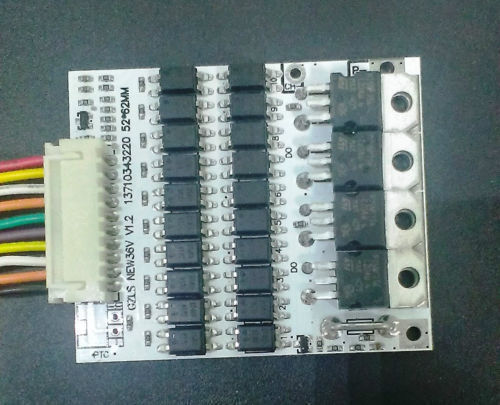

Features:

size : 53*63MM

Over charge voltage test: VCU 4.25V ±0.05V (4.20-4.35V // each 0.05V per step)

Over charge voltage resume: VCD 4.10-4.00V

Over discharge voltage test: VDD2.50V ±0.1V (2.5-3.0V // each 0.05V per step)

Over discharge voltage resume: VDU 2.80V ±0.V1

Operating current: ≤300UA

Short circuit protection: 40A±3A

Short circuit protection duration: 500MS

Temperature protection: 55 / 65 / 75 degree

Typical output current: 30A

Max. output current: 45A

Balance voltage for single cell:4.19V ±0.02V

Balance current for single cell:≤ 55MA

Charging current:≤10A

Dim. 53 x 63mm (L x W)

In case anyone is wondering why I made a 10s24p battery (240-18650's) it's not cause I intend on going to the moon and back without refueling it's because I bought them like that from some guy on craigslist who gave up on his own ebike project after making it. I'm gonna break it up (cut the tabs between each 24-pack and untape/uncardboard them from one another) into 10 24p groups so I can put a balance lead on each set then maybe I'll put cardboard and tape around each pack and connect them in series with wires/connectors so if one goes seriously wrong it won't damage the others as much, they can be traded out easier etc. I don't trust just charging it as is without balance leads cause I don't really know much about what testing the guy did prior to connecting it all (it measures 35 point something volts as it came). For some odd reason one of the packs of 24 has rust all over the top of it including on the solder tabs as if battery acid poured all over it after it was all soldered together but I haven't found the source yet so perhaps some had burst and he removed them. I had someone pick the cells up for me out of town and the guy who sold them was Chinese I think and spoke very poor English so I wasn't able to understand any of his answers but for $100 for what looks to be around 405 18650's I think it's a pretty sweet deal. He even threw in a few sets of flatish small cellphone looking batteries strung/taped together that I think may have been from some kind of old/oddschool laptops and some of the laptop packs aren't even hacked open yet but I included them in my total estimate.

Features:

size : 53*63MM

Over charge voltage test: VCU 4.25V ±0.05V (4.20-4.35V // each 0.05V per step)

Over charge voltage resume: VCD 4.10-4.00V

Over discharge voltage test: VDD2.50V ±0.1V (2.5-3.0V // each 0.05V per step)

Over discharge voltage resume: VDU 2.80V ±0.V1

Operating current: ≤300UA

Short circuit protection: 40A±3A

Short circuit protection duration: 500MS

Temperature protection: 55 / 65 / 75 degree

Typical output current: 30A

Max. output current: 45A

Balance voltage for single cell:4.19V ±0.02V

Balance current for single cell:≤ 55MA

Charging current:≤10A

Dim. 53 x 63mm (L x W)