You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

E-bike + carbon frame + 52V. 18650 + BMC motor

- Thread starter soaresdacosta

- Start date

soaresdacosta

10 kW

Hi guys,

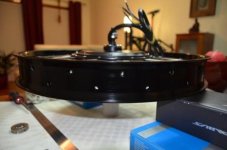

Slowly put the bike together.

I bought 40 sapim spokes from "em3ev" with 140mm...I think they are 2mm too long.

Luis.

Slowly put the bike together.

I bought 40 sapim spokes from "em3ev" with 140mm...I think they are 2mm too long.

Luis.

Attachments

-

DSC_0845.JPG66.1 KB · Views: 3,304

DSC_0845.JPG66.1 KB · Views: 3,304 -

DSC_0847.JPG68.1 KB · Views: 3,304

DSC_0847.JPG68.1 KB · Views: 3,304 -

DSC_0848.JPG59.4 KB · Views: 3,304

DSC_0848.JPG59.4 KB · Views: 3,304 -

DSC_0849.JPG63.8 KB · Views: 3,304

DSC_0849.JPG63.8 KB · Views: 3,304 -

DSC_0850.JPG55.1 KB · Views: 3,304

DSC_0850.JPG55.1 KB · Views: 3,304 -

DSC_0851.JPG59.3 KB · Views: 3,304

DSC_0851.JPG59.3 KB · Views: 3,304 -

DSC_0852.JPG57.9 KB · Views: 3,304

DSC_0852.JPG57.9 KB · Views: 3,304 -

DSC_0853.JPG61.5 KB · Views: 3,304

DSC_0853.JPG61.5 KB · Views: 3,304 -

DSC_0855.JPG63.3 KB · Views: 3,304

DSC_0855.JPG63.3 KB · Views: 3,304

soaresdacosta

10 kW

Hi guys,

Some parts arrive today...no time lost on put them in place.

Jimboyr6, the problem is, I do not have more thread on the spoke to tight the rim. will see.

Luis.

Some parts arrive today...no time lost on put them in place.

Jimboyr6, the problem is, I do not have more thread on the spoke to tight the rim. will see.

Luis.

Attachments

the12be

100 W

- Joined

- Sep 10, 2012

- Messages

- 137

have you tried using a die set to add a longer thread ?

http://www.screwfix.com/c/tools/tap-die-sets/cat831180

just clamp each spoke in a vice put oil on the ends and slowly rock the die over your thread put the spokes in the rim mark off the excess thread with a black pen undo the spokes put the nut back on (leave the nipple nut ON when cutting the spokes so you can reattach the nipple nut on and off ) cut off then take the nuts off and re-spoke the wheel

http://www.screwfix.com/c/tools/tap-die-sets/cat831180

just clamp each spoke in a vice put oil on the ends and slowly rock the die over your thread put the spokes in the rim mark off the excess thread with a black pen undo the spokes put the nut back on (leave the nipple nut ON when cutting the spokes so you can reattach the nipple nut on and off ) cut off then take the nuts off and re-spoke the wheel

soaresdacosta

10 kW

the12be, you are the man. Thanks a lot. I will try that.

Luis.

Luis.

soaresdacosta

10 kW

Hi guys,

Some parts arrive, and just work a little on the bike.

And put a Christmas tree together.

Luís.

Some parts arrive, and just work a little on the bike.

And put a Christmas tree together.

Luís.

Attachments

Wolfeman

1 kW

Soaresdacosta,

Thanks for the great build thread. You are building the way I'd like to build if I didn't have so many other responsibilities.... 8) I know it takes time to document, photograph and post, thank you for your time.

Thanks for the great build thread. You are building the way I'd like to build if I didn't have so many other responsibilities.... 8) I know it takes time to document, photograph and post, thank you for your time.

soaresdacosta

10 kW

Hello crew,

the12be, For now, I didn't try the die. I still have 0.5mm of tread on each spoke, and looks good. This bike its for the free time...so no rain.

hedsik, I will go with 72volts of lifepo4 18650. The 24s 10amps "lipo" I have, its sold...gone with the CUBE.

Wolfeman, Thanks for your words. Maybe you can build one, your way in the future.

Jimboyr6 , I take some measurements on the frame, before I buy the rims...I think, I didn't fu...up.

Again, Thanks for the support.

Luis.

the12be, For now, I didn't try the die. I still have 0.5mm of tread on each spoke, and looks good. This bike its for the free time...so no rain.

hedsik, I will go with 72volts of lifepo4 18650. The 24s 10amps "lipo" I have, its sold...gone with the CUBE.

Wolfeman, Thanks for your words. Maybe you can build one, your way in the future.

Jimboyr6 , I take some measurements on the frame, before I buy the rims...I think, I didn't fu...up.

Again, Thanks for the support.

Luis.

soaresdacosta

10 kW

Hello guys,

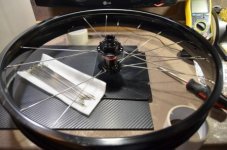

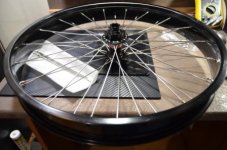

After some holidays, is time to continue the project.

I order some spokes from em3ev (great company) and assemble my front wheel.

Next task, its going to be, the rear wheel assemble...it need some metal fabrication on the dropouts.

Take care,

Luis.

After some holidays, is time to continue the project.

I order some spokes from em3ev (great company) and assemble my front wheel.

Next task, its going to be, the rear wheel assemble...it need some metal fabrication on the dropouts.

Take care,

Luis.

Attachments

-

DSC_0986.JPG63.5 KB · Views: 2,922

DSC_0986.JPG63.5 KB · Views: 2,922 -

DSC_0994.JPG68.4 KB · Views: 2,922

DSC_0994.JPG68.4 KB · Views: 2,922 -

DSC_0996.JPG70.8 KB · Views: 2,922

DSC_0996.JPG70.8 KB · Views: 2,922 -

DSC_0997.JPG69.8 KB · Views: 2,922

DSC_0997.JPG69.8 KB · Views: 2,922 -

DSC_0010.JPG77.2 KB · Views: 2,922

DSC_0010.JPG77.2 KB · Views: 2,922 -

DSC_0016.JPG66.2 KB · Views: 2,922

DSC_0016.JPG66.2 KB · Views: 2,922 -

DSC_0017.JPG65.3 KB · Views: 2,922

DSC_0017.JPG65.3 KB · Views: 2,922 -

DSC_0019.JPG60.8 KB · Views: 2,922

DSC_0019.JPG60.8 KB · Views: 2,922 -

DSC_0020.JPG65.9 KB · Views: 2,922

DSC_0020.JPG65.9 KB · Views: 2,922 -

DSC_0021.JPG60.8 KB · Views: 2,922

DSC_0021.JPG60.8 KB · Views: 2,922 -

DSC_0032.JPG56.4 KB · Views: 2,922

DSC_0032.JPG56.4 KB · Views: 2,922

Wolfeman

1 kW

Really stoked to see an update on this project. Thanks for posting Soaresdacosta. Beautiful pics and parts as usual. 8)

soaresdacosta

10 kW

Hello crew,

Jimboyr6, thanks...is good to be back. 8)

Wolfeman, thanks for your words.

Im going to enter in a part of the project, that im not happy to...dropouts. I need to design and made some new dropouts. Im thinking in using a company like "BigBlueSaw". In the mean time, I will build my battery box, this time, in aluminium.

Luis.

Jimboyr6, thanks...is good to be back. 8)

Wolfeman, thanks for your words.

Im going to enter in a part of the project, that im not happy to...dropouts. I need to design and made some new dropouts. Im thinking in using a company like "BigBlueSaw". In the mean time, I will build my battery box, this time, in aluminium.

Luis.

soaresdacosta

10 kW

Hello guys,

I really need to resolve this torque-arms big problem... for better try to take measures, I disassemble the rear swing arm...more to came on this.

In a more easy and fast job, I strait the front wheel...Job well done.

Luís

I really need to resolve this torque-arms big problem... for better try to take measures, I disassemble the rear swing arm...more to came on this.

In a more easy and fast job, I strait the front wheel...Job well done.

Luís

Attachments

It looks like the dropout will need to be machined or sawed out so the motor axle can fit. Does the factory dropout have a pinch bolt?

What is the diameter of the axle hole in the dropout?

What is the thickness of the flat section on the motor axle?

If the flat is the same as the hole diameter then you might do OK to just make a slot. Otherwise you may need a new part that clamps onto the axle and bolts to the swingarm.

What is the diameter of the axle hole in the dropout?

What is the thickness of the flat section on the motor axle?

If the flat is the same as the hole diameter then you might do OK to just make a slot. Otherwise you may need a new part that clamps onto the axle and bolts to the swingarm.

soaresdacosta

10 kW

Hello guys,

fechter, thanks for your interest in help.

The hole diameter, is a little bigger than the flat side (2mm). In one side, there is a pinch bolt, and maybe I can compensate with that. In the chain side, there is no pinch bolt.

I was more incline, in a part that clamps to the axle and bolts to the swingarm, like some folks did with the Giant. (Kiwi-dropouts).

Luís.

fechter, thanks for your interest in help.

The hole diameter, is a little bigger than the flat side (2mm). In one side, there is a pinch bolt, and maybe I can compensate with that. In the chain side, there is no pinch bolt.

I was more incline, in a part that clamps to the axle and bolts to the swingarm, like some folks did with the Giant. (Kiwi-dropouts).

Luís.

Attachments

There's been some of those posted before. Here's a few:

https://endless-sphere.com/forums/viewtopic.php?f=31&t=49635&start=50

https://endless-sphere.com/forums/viewtopic.php?f=2&t=22898

https://endless-sphere.com/forums/viewtopic.php?f=6&t=33767&start=50

Google image search page:

https://www.google.com/search?q=pinch+bolt+dropouts&biw=1536&bih=746&source=lnms&tbm=isch&sa=X&ved=0ahUKEwi0z8-Tle3RAhVK_mMKHaMQDk0Q_AUIBygC#tbm=isch&q=pinch+bolt+dropouts+site:+endless-sphere.com&imgrc=_

I would recommend the type with a pinch bolt if you have space. These will resist getting loose the best.

https://endless-sphere.com/forums/viewtopic.php?f=31&t=49635&start=50

https://endless-sphere.com/forums/viewtopic.php?f=2&t=22898

https://endless-sphere.com/forums/viewtopic.php?f=6&t=33767&start=50

Google image search page:

https://www.google.com/search?q=pinch+bolt+dropouts&biw=1536&bih=746&source=lnms&tbm=isch&sa=X&ved=0ahUKEwi0z8-Tle3RAhVK_mMKHaMQDk0Q_AUIBygC#tbm=isch&q=pinch+bolt+dropouts+site:+endless-sphere.com&imgrc=_

I would recommend the type with a pinch bolt if you have space. These will resist getting loose the best.

soaresdacosta

10 kW

Hello people,

fechter, thanks again for your time.

Just one question. I definitely, go with a system, like the "kiwi-dropouts", and absolutely go with pinch-bolt. What material ? Aluminium ? Its more easy to work with...or steel ?

Luís.

fechter, thanks again for your time.

Just one question. I definitely, go with a system, like the "kiwi-dropouts", and absolutely go with pinch-bolt. What material ? Aluminium ? Its more easy to work with...or steel ?

Luís.

the12be

100 W

- Joined

- Sep 10, 2012

- Messages

- 137

Steel think of your axle as a (your bikes volt ?) drill you need to stop it from spinning

http://em3ev.com/store/index.php?route=product/product&product_id=88

hope this helps

http://em3ev.com/store/index.php?route=product/product&product_id=88

hope this helps

soaresdacosta

10 kW

Hi guys,

the12be, thanks. Yes I understand.

I think I see some guys using aluminium for the torque arms. I can work with aluminium, but not with steel.

Luís.

the12be, thanks. Yes I understand.

I think I see some guys using aluminium for the torque arms. I can work with aluminium, but not with steel.

Luís.