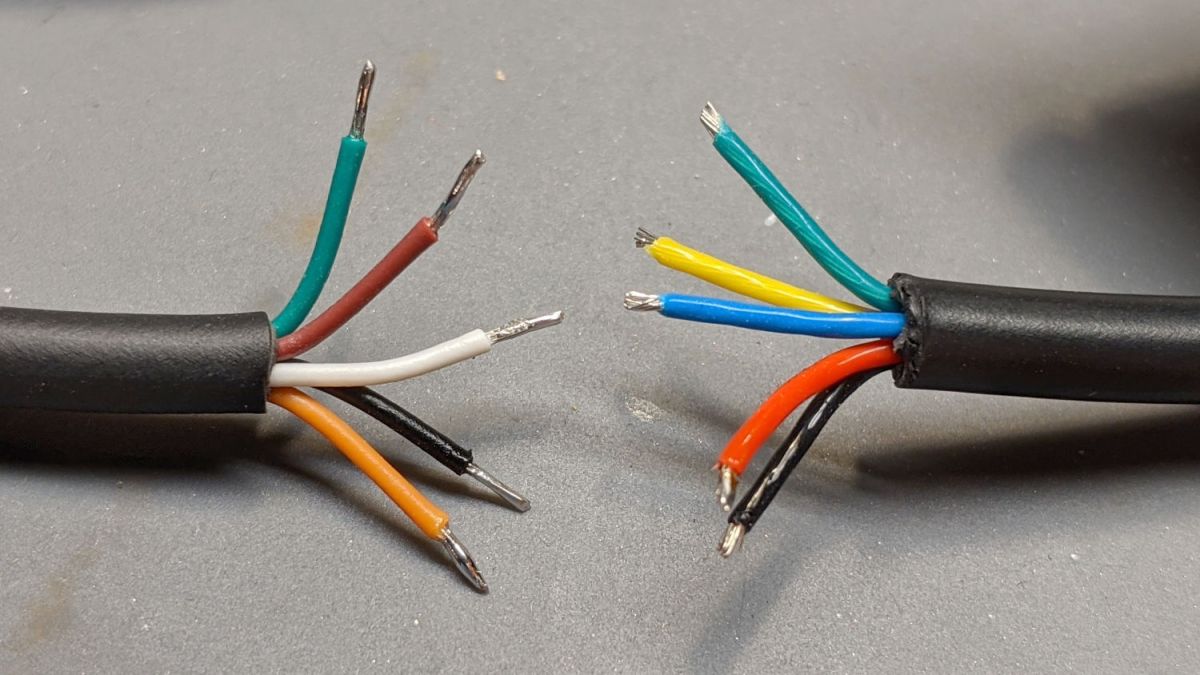

Had a bit of a tumble with my E-bike and the cable for the DP C18 display was tore and it cut some leads, thought it would be an easy fix; just solder back the leads. Boy was I wrong.

The leads must have shorted against each other and now my BBS02B is completely dead, wont turn on at all.

- I tested another cable harness

- I disassembled the engine and checked the connections

Thing is I tested it with my mates 850C display and it was still dead, so I tested my DP C18 with my mates bike (also BBS02B) and it turned on, but now he's throttle is dead and his speed sensor is completely dead (no light when it passes) (Error: 21H).

So my faulty DP C18 has probably shorted out both our controllers for our BBS02B's, I'm at a loss as what to do.

Only thing I can think of is updating to danielnilsson9 firmware and keep my fingers crossed it solves the problems for us both, just ordered the programming cable.

Anyone have any thoughts?

Probably have to buy 2 new BBS02B kits, feel like an asshole for bricking my mates bike..

The leads must have shorted against each other and now my BBS02B is completely dead, wont turn on at all.

- I tested another cable harness

- I disassembled the engine and checked the connections

Thing is I tested it with my mates 850C display and it was still dead, so I tested my DP C18 with my mates bike (also BBS02B) and it turned on, but now he's throttle is dead and his speed sensor is completely dead (no light when it passes) (Error: 21H).

So my faulty DP C18 has probably shorted out both our controllers for our BBS02B's, I'm at a loss as what to do.

Only thing I can think of is updating to danielnilsson9 firmware and keep my fingers crossed it solves the problems for us both, just ordered the programming cable.

Anyone have any thoughts?

Probably have to buy 2 new BBS02B kits, feel like an asshole for bricking my mates bike..