speedmd

10 MW

+1 on removing the end screw.

I think BEE must be your last name. Magilla maybe your first. :lol:

:lol:

I think BEE must be your last name. Magilla maybe your first.

bee said:Any idea how to remove the freewheel? I hammered on it for a while but it didn't budge. It seems to be the standard slotted keyway, but this one is stuck on there really good. I guess I need something like a bearing puller?

parts that are more stuck together than others

skyungjae said:iovaykind said:Just wondering if this is the case for everyone with the stock GnG belt driven 48v kit:

At certain RPMs there is a loud resonance which makes the kit much louder. There is a significant resonance that makes a loud howling sound right around 70% throttle. Does anyone else get this, and if so, has there been a solution for this yet?

Try taking off the little belt shield thingy.

LightningRods said:Skyungjae didn't you work out a better secondary driver freewheel? Are you thinking the jackshaft end may be different now?

skyungjae said:I think those heavy duty freewheels that Cyclone sells are a fantastic cost solution in comparison to the White Industries. I'm pretty sure they're identical to the ACS 10 hole flanged freewheels minus the branding.

You using the pedals at all now? I've been dropping my sprocket size slowly to improve strength/reliability.scrone said:I passed 1000 km today mostly trail riding.

View attachment 1

Very happy with the T-50 staple mod and the 24 tooth sprocket. Now I can climb the steepest hill I know and barely slow down. I was trail blazing through tall grass and brush (just to get away from the dog walkers).

I attached the 24 tooth directly to the freewheel. Check the Robertson screws- another Canadian invention.

Whiplash said:What is the T-50 staple mod?

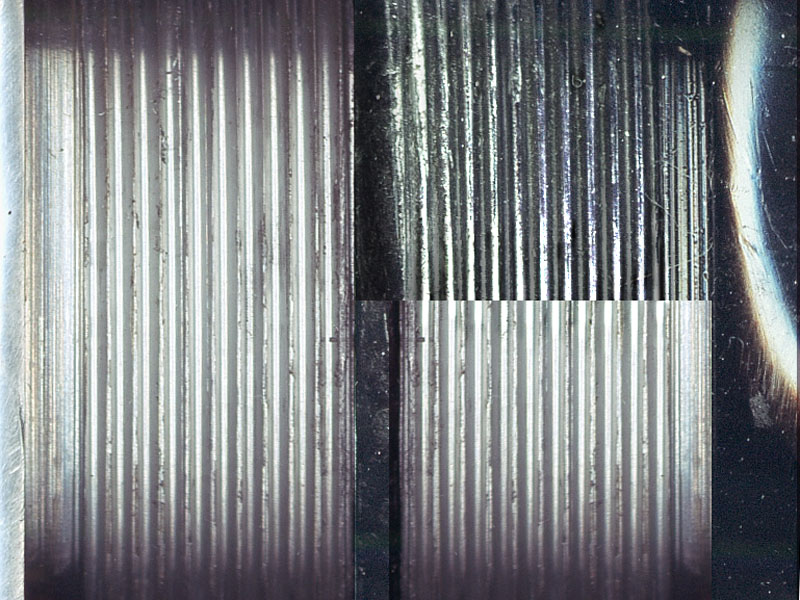

I should imagine they're both made by Long Yih in Taiwan: http://www.dnp.com.tw/pro2.asp?ID=5&tmpEdtion=englishLightningRods said:Here is the Cyclone Heavy Duty next to the ACS. Pretty identical other than the color of the metal.skyungjae said:I think those heavy duty freewheels that Cyclone sells are a fantastic cost solution in comparison to the White Industries. I'm pretty sure they're identical to the ACS 10 hole flanged freewheels minus the branding.

bee said:You using the pedals at all now? I've been dropping my sprocket size slowly to improve strength/reliability.

E-Norco said:Whiplash said:What is the T-50 staple mod?

http://endless-sphere.com/forums/viewtopic.php?f=28&t=46891#p686506

speedmd said:Good catch LightningRods. Fortunately many have been able to screw on a standard freewheel and still have some threads remaining on the crank arm. Answers the 1.37 vs 1.375 issue for good. It is neither. I am leaving mine assembled until it dies.Also answers why I can find the metric 1mm pitch dies on Ali but very few 1.375x24 anywhere in the east. The Taiwan crank threads look much higher quality from your photo also. Looks like it will be best to start over with a completely new setup.

http://www.tracytools.com/taps-and-dies/brass-cycle-special/13-8-x-24-tpispeedmd said:The M35x1.0 taps and dies are common. Ebay has a bunch listed for under $20. Not any of these tools I can find reasonable for the english thread. Me thinks, that is where this may be headed eventually on this secondary (non hub) type items.

Miles said:http://www.tracytools.com/taps-and-dies/brass-cycle-special/13-8-x-24-tpispeedmd said:The M35x1.0 taps and dies are common. Ebay has a bunch listed for under $20. Not any of these tools I can find reasonable for the english thread. Me thinks, that is where this may be headed eventually on this secondary (non hub) type items.