crossbreak

1 MW

Former Project Name: MagicPie2 20" Hotrod Project with 52T Hammerschmidt

Hi folks,

inspired by izeman http://endless-sphere.com/forums/viewtopic.php?f=3&t=38848 I want to start my own conversion.

from izeman's thread

quote

I'll also order some JB-Weld. I like your long swing arm, but I can't build such a thing. Now I will elongate mine with 4x 5mm thick AL-7075 sheets on both sides, which will be fastened on the original swing arm with JB-Weld. I change my motor for a cheaper MagicPie2 in a casted 20"rim and use the HS3540 on a different bike. Hope the MagicPie2 can stand the 40amps@24s lipo I wanna use

Thx for your tips about tires, they are so cheap! Hope they fit the 20" MagicPie2 rim properly :? http://www.ebay.de/itm/300856503835?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649

I will use 24" front, hope it will look different than neptronix bike

http://endless-sphere.com/forums/viewtopic.php?f=6&t=35060&start=50#p514219

Also got a Hammerschmidt drive on the bay that will be fitted so I can still pedal at 45mph

/quote

Big Hubmotors do a great job in a small rim. The largest i found that is relatively lightweight is the MagicPie2, it is 300mm in diameter.

Drawback1: Need a huge overdrive from the pedals to the wheel

Solution: Hammerschmidt drive gives a factor 1.6 extra overdrive. 52T chainwheel and 32-11T sprocket cassette means 52/11x1.6=7.56 overdrive ratio, or 60kph @ lazy 80rpm crank rpm, with a 20" wheel.

Problem: Hammerschmidt drive comes with 24T chainwheel max, solution: Make an adapter from 7075 alloy

Drawback2: MagicPie has only 7.4KV http://endless-sphere.com/forums/viewtopic.php?f=30&t=34750&start=75#p516494

http://endless-sphere.com/forums/viewtopic.php?f=30&t=34750&start=75#p516494

Solution: Terminate it in Delta, so it has 7.4*1,73=12.8KV

I want to use a 26" MTB frame, since it has nice suspension, I ride this bike since 3 years, first with turnigy 80-100 middrive, then with 250W tongxin coinverted to middrive with derailleur, then with 9-speed SRAM internal geared shifter Hub, then with Goldenmotor MBG geared hub, then with Clyte HS3540, all in a 26" rim.

I'm fed up with 26", too lazy to respoke my HS3540, now I go for a MagicPie2 in a casted 20" rim.

Drawback: The rim isn't very stiff since it's made from alloy 6000

Solution: Stiffen the rim by adding alloy pipes, fastened with JB-Weld, and use fat 16-2.5 moped tires

Drawback: Looks ugly

Solution: Make it a slice wheel, like the ones used in a race bicycle

Hotrod

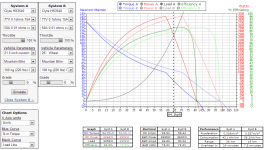

Controller: 18s Lipo, 24Fet IRFB3077, 85amps sounds much for this motor, but in Delta the current gets divided by two. The max phase amps is set to 115amps, so each winding sees only 57.5amps maximum. That should be ok if properly cooled and monitored by the Cycla Analyst.

Cooling: Drilling holes into a hub is very common these days. I will coat the stator with brake caliper paint to make it waterproof

BIG PROBLEM:

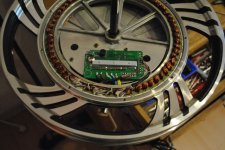

I thought that MP2 has an external controller, mine has an internal controller :x did I get the MP3 or what is wrong here?!?!

Hi folks,

inspired by izeman http://endless-sphere.com/forums/viewtopic.php?f=3&t=38848 I want to start my own conversion.

from izeman's thread

quote

I'll also order some JB-Weld. I like your long swing arm, but I can't build such a thing. Now I will elongate mine with 4x 5mm thick AL-7075 sheets on both sides, which will be fastened on the original swing arm with JB-Weld. I change my motor for a cheaper MagicPie2 in a casted 20"rim and use the HS3540 on a different bike. Hope the MagicPie2 can stand the 40amps@24s lipo I wanna use

Thx for your tips about tires, they are so cheap! Hope they fit the 20" MagicPie2 rim properly :? http://www.ebay.de/itm/300856503835?ssPageName=STRK:MEWNX:IT&_trksid=p3984.m1497.l2649

I will use 24" front, hope it will look different than neptronix bike

http://endless-sphere.com/forums/viewtopic.php?f=6&t=35060&start=50#p514219

Also got a Hammerschmidt drive on the bay that will be fitted so I can still pedal at 45mph

/quote

Big Hubmotors do a great job in a small rim. The largest i found that is relatively lightweight is the MagicPie2, it is 300mm in diameter.

Drawback1: Need a huge overdrive from the pedals to the wheel

Solution: Hammerschmidt drive gives a factor 1.6 extra overdrive. 52T chainwheel and 32-11T sprocket cassette means 52/11x1.6=7.56 overdrive ratio, or 60kph @ lazy 80rpm crank rpm, with a 20" wheel.

Problem: Hammerschmidt drive comes with 24T chainwheel max, solution: Make an adapter from 7075 alloy

Drawback2: MagicPie has only 7.4KV

Solution: Terminate it in Delta, so it has 7.4*1,73=12.8KV

I want to use a 26" MTB frame, since it has nice suspension, I ride this bike since 3 years, first with turnigy 80-100 middrive, then with 250W tongxin coinverted to middrive with derailleur, then with 9-speed SRAM internal geared shifter Hub, then with Goldenmotor MBG geared hub, then with Clyte HS3540, all in a 26" rim.

I'm fed up with 26", too lazy to respoke my HS3540, now I go for a MagicPie2 in a casted 20" rim.

Drawback: The rim isn't very stiff since it's made from alloy 6000

Solution: Stiffen the rim by adding alloy pipes, fastened with JB-Weld, and use fat 16-2.5 moped tires

Drawback: Looks ugly

Solution: Make it a slice wheel, like the ones used in a race bicycle

Hotrod

Controller: 18s Lipo, 24Fet IRFB3077, 85amps sounds much for this motor, but in Delta the current gets divided by two. The max phase amps is set to 115amps, so each winding sees only 57.5amps maximum. That should be ok if properly cooled and monitored by the Cycla Analyst.

Cooling: Drilling holes into a hub is very common these days. I will coat the stator with brake caliper paint to make it waterproof

BIG PROBLEM:

I thought that MP2 has an external controller, mine has an internal controller :x did I get the MP3 or what is wrong here?!?!