Hi all,

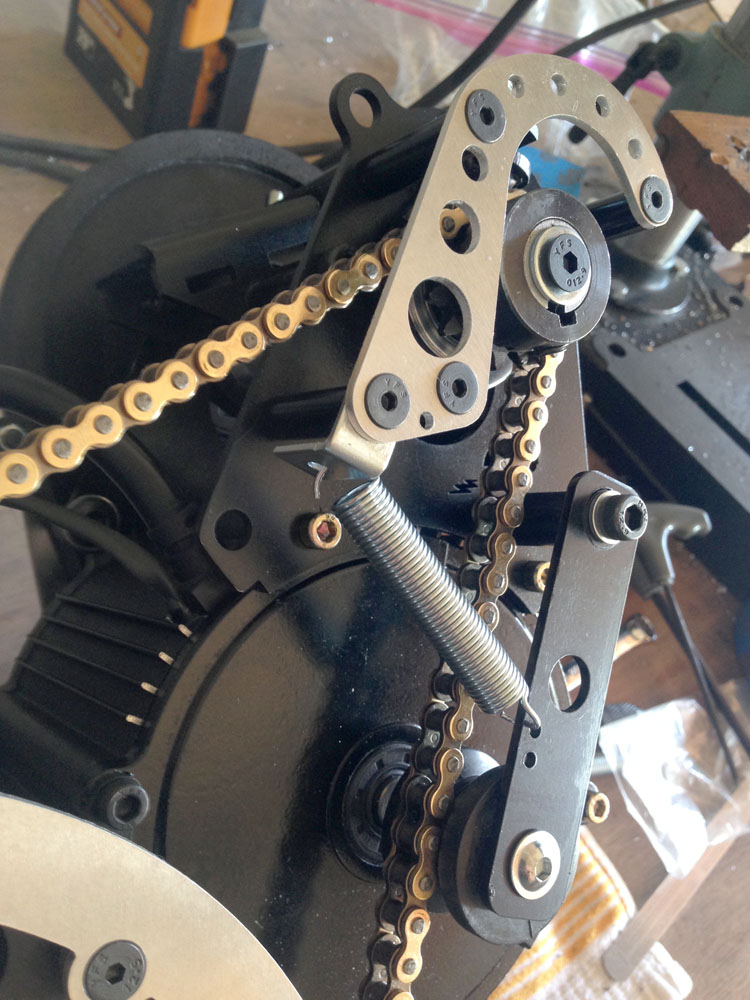

Am working through some issues with the Lightning Rods (small block) installation on my bike.

My lightning rods kit has 2 final drive chain rings.

I've just discovered that the final drive chain is rubbing on one of the locking bolts for the #219 chain, when the chain is on the small chain ring.

Would I be better off adding another BB spacer (and trying to re adjuster the front derailleur, and the #219 chain jack shaft, and anything else that ends up out of alignment ), or remove one of the two washers on the locking and grinding a bit off the top of the bolt ?

Thanks.

Am working through some issues with the Lightning Rods (small block) installation on my bike.

My lightning rods kit has 2 final drive chain rings.

I've just discovered that the final drive chain is rubbing on one of the locking bolts for the #219 chain, when the chain is on the small chain ring.

Would I be better off adding another BB spacer (and trying to re adjuster the front derailleur, and the #219 chain jack shaft, and anything else that ends up out of alignment ), or remove one of the two washers on the locking and grinding a bit off the top of the bolt ?

Thanks.