You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Loaded Tesseract Carbon Single VESC 6355 10S4P

- Thread starter whitepony

- Start date

whitepony

10 kW

- Joined

- Feb 19, 2015

- Messages

- 663

wow okp, looks really awesome!!

I didnt have too much time today and sadly my finish didnt work out so well due to the air bubbles I couldnt get rid of. sanded the bubbles off today ... probably shouldnt have used my 24hour cure-time air grade epoxy for coating and instead get a gelcoat thats actually made for finishing laminate surfaces. what do you use as finishing layer cause yours look really great?

Im SUPERhappy about the flex, its simply perfect! stock tesseract is a little bit too stiff for eboarding, was hoping for a deck that flexes just a tiny bit more ... and thats EXACTLY what I got. couldnt be better really, it ended up in an absolute sweet spot.

with my last bit of time today, I managed to sink in 7 m4 inserts and fixate the case. pretty happy about how slim it is, you can barely see the case from a police officer perspective :lol:

I dont even want to post these pictures because they simply dont do the carbon quality justice. its all partially sanded and partially glossy, which gives it a very rugged look but i know that I wont do a proper finish very soon, so ill have to live with it for a few days or weeks. got also cool black and orange eloxated aluminum screws incoming with extra slim washers.

I didnt have too much time today and sadly my finish didnt work out so well due to the air bubbles I couldnt get rid of. sanded the bubbles off today ... probably shouldnt have used my 24hour cure-time air grade epoxy for coating and instead get a gelcoat thats actually made for finishing laminate surfaces. what do you use as finishing layer cause yours look really great?

Im SUPERhappy about the flex, its simply perfect! stock tesseract is a little bit too stiff for eboarding, was hoping for a deck that flexes just a tiny bit more ... and thats EXACTLY what I got. couldnt be better really, it ended up in an absolute sweet spot.

with my last bit of time today, I managed to sink in 7 m4 inserts and fixate the case. pretty happy about how slim it is, you can barely see the case from a police officer perspective :lol:

I dont even want to post these pictures because they simply dont do the carbon quality justice. its all partially sanded and partially glossy, which gives it a very rugged look but i know that I wont do a proper finish very soon, so ill have to live with it for a few days or weeks. got also cool black and orange eloxated aluminum screws incoming with extra slim washers.

great job ! don't worry for the rough surface; just sand it with 180/240 and once you are happy; apply standard epoxy resin (no gel coat or whatsoever) that you hot with an hairdryer. this will work fine and make this a mirror. if you want a matte finish, just use a spray can varnish from a graffiti shop

@piyo : the tacon performs flawlessly. Really consistent with good torque and an impressive boosting capability when you are at speed. Hill climbing is pretty easy. Maybe a little bit more than the RSPEC due to the higher kv. On 10S this thing is a beast.

@piyo : the tacon performs flawlessly. Really consistent with good torque and an impressive boosting capability when you are at speed. Hill climbing is pretty easy. Maybe a little bit more than the RSPEC due to the higher kv. On 10S this thing is a beast.

you also have to use a brush , as you were painting but with a ultra little amount resin from one side to the other

you also need to ensure that you don't put any finger on the deck or stuff like that; I usually clean the deck with acetone or white spirit or alcool...

you also need to ensure that you don't put any finger on the deck or stuff like that; I usually clean the deck with acetone or white spirit or alcool...

bandaro

10 kW

okp said:great job ! don't worry for the rough surface; just sand it with 180/240 and once you are happy; apply standard epoxy resin (no gel coat or whatsoever) that you hot with an hairdryer. this will work fine and make this a mirror. if you want a matte finish, just use a spray can varnish from a graffiti shop.

whitepony said:basically thats what I did, but then lots of small air bubbles came up. :/

Best way I have found it to mix up the resin (don't worry too much about bubbles in it at this stage) and then hold it high above the workpiece and slowly pour the resin on. By holding it up high, you are letting the resin form a very thin line to the deck, effectively lowering surface tension and removing any air bubbles. I've found this to be as or more effective as degassing in a chamber, as it is instant and doesn't create heat. Then move it around gently with a fine, CLEAN brush. Leave it away from dust and bugs to cure and you are done. A hair dryer can be used on high heat, low speed to expand bubbles and pop them, but generally isn't needed.

For awkward shapes (such as carbon bike frames) repairs can be blended in to look invisible by sanding to 800 grit and then given a clear coat of auto paint. This technique would also be effective on a deck, but probably not the fastest method.

Also, to both of you, why does the tray material look so thick? What is the layup you used? How many layers of what weight and fibres was it?

whitepony

10 kW

- Joined

- Feb 19, 2015

- Messages

- 663

that heat gun air popping thing didnt work well for me. think ill just give it a try some other day when I have more time.

think both of our cases are VERY thin. okp used 1x GFK, 2x Carbon and thats what I did too (just following his experience). my case is so light that wind blew it away when it was laying in the sun outside. :lol:

the reason why we have "thick" looking material is, that okp seemed to have used VERY thick rubber/neoprene style band, probably to get the motor wires through between board and case (at least I can see the receiver antenna, its a cool idea but makes the case appear quite thick).

I used a 3mm neoprene band, so make sure that I will never ever hear any enclosure vs board rattling and its waterproofing the enclosure (where otherwise there would be small air gaps, that would suck in fluids with the neat capillary effect).

see here: m4 inserts & 10x3mm adhesive neoprene band:

think both of our cases are VERY thin. okp used 1x GFK, 2x Carbon and thats what I did too (just following his experience). my case is so light that wind blew it away when it was laying in the sun outside. :lol:

the reason why we have "thick" looking material is, that okp seemed to have used VERY thick rubber/neoprene style band, probably to get the motor wires through between board and case (at least I can see the receiver antenna, its a cool idea but makes the case appear quite thick).

I used a 3mm neoprene band, so make sure that I will never ever hear any enclosure vs board rattling and its waterproofing the enclosure (where otherwise there would be small air gaps, that would suck in fluids with the neat capillary effect).

see here: m4 inserts & 10x3mm adhesive neoprene band:

whitepony

10 kW

- Joined

- Feb 19, 2015

- Messages

- 663

hihi, I leanrt sonething new about epoxy resin: its an exothermic reaction with the hardener, that much I knew. So i went heating up the mix up to about 40*C, coated the board & case again the mix started smoking, then boiling, i brought the cup with resin outside quickly and 2min later it was fully crystallized and blazing hot. think the thermodynamics werent in balance anymore, couldnt get rid of the exothermic reaction heat.

so yea, not very high hopes for this resin coat either, should just go for matte clear coating.

so yea, not very high hopes for this resin coat either, should just go for matte clear coating.

normally there's no need to heat this up to 40 deg. otherwise the energy from the exothermic reaction will be added on top of the 40 deg. and then it gets too hot.

roomtemp is enough.

try that on an extra piece and see how that works. in case it still gets too hot, use less hardener.

Uwe

roomtemp is enough.

try that on an extra piece and see how that works. in case it still gets too hot, use less hardener.

Uwe

whitepony

10 kW

- Joined

- Feb 19, 2015

- Messages

- 663

this finishing business is annoying. I wish I didnt watch youtube videos about air bubbles in resin surfaces - I tried the heat gun, didnt work so well ... another thing that looked great in the video was to spray an acetone mist on the resin surface to kill all bubbles. well, it killed the bubbles, but probably the acetone mist wasnt fine enough, so there are "islands" of no resin now which looks bad too.

problem is that I dont want to hurt the carbon, so I always have to sand very carefully which means it takes a lot of time. think Im done with resin coating. maybe I should test on some practice samples first before I have to sand my board & enclosure over and over.

apart from the finish, Im pretty much done. the enclosure is a perfect fit on the 8 M4 inserts, my triple 4mm gold connector charge/on-off-"switch" is installed on the enclosure, the motor is connected to the vesc via the motor wire channel with 3 12AWG cables, VESC is in place and cables are installed. but something in me just couldnt go skating and leave the surface sanded and ugly.

Ill just take my time with the board, no need to rush things with my evolve around (wish my vescs would arrive for my trampa which is also a construction site right now).

problem is that I dont want to hurt the carbon, so I always have to sand very carefully which means it takes a lot of time. think Im done with resin coating. maybe I should test on some practice samples first before I have to sand my board & enclosure over and over.

apart from the finish, Im pretty much done. the enclosure is a perfect fit on the 8 M4 inserts, my triple 4mm gold connector charge/on-off-"switch" is installed on the enclosure, the motor is connected to the vesc via the motor wire channel with 3 12AWG cables, VESC is in place and cables are installed. but something in me just couldnt go skating and leave the surface sanded and ugly.

Ill just take my time with the board, no need to rush things with my evolve around (wish my vescs would arrive for my trampa which is also a construction site right now).

WeeChumlee

1 kW

- Joined

- Jul 8, 2015

- Messages

- 346

@ OKP & Whitepony

You guys both run boards with a 63mm motor and a VESC and seem to have no problems and plenty of power.

Since changing to a VESC on my single my board has lost a lot of power and the VESC heats up. I an therefore only presume I have a setting problem.

I am not using FOC.

Any chance you could post your VESC settings so I can compare?

On my dual 50mm setup I am not having any problems so I am a bit lost.

THanks

You guys both run boards with a 63mm motor and a VESC and seem to have no problems and plenty of power.

Since changing to a VESC on my single my board has lost a lot of power and the VESC heats up. I an therefore only presume I have a setting problem.

I am not using FOC.

Any chance you could post your VESC settings so I can compare?

On my dual 50mm setup I am not having any problems so I am a bit lost.

THanks

whitepony

10 kW

- Joined

- Feb 19, 2015

- Messages

- 663

hey man, I wish I actually knew why I have temperature problems with my trampa and not with my tesseract. both run 63mm motors with vesc. settings are straightforward, BLDC, motor params autodetected, battery current 60A, motor current 60A (rspecc 6355, tesseract) and 80A (sk6374 trampa), 45/32V battery limits and nunchuck/GT2B stuff. :?

WeeChumlee

1 kW

- Joined

- Jul 8, 2015

- Messages

- 346

Hi Whitepony

Yeah, weird. The only difference 12S made to the board is that it is much quieter - apart from that not a thing. No more power at all.

Hmm, only thing I can still do is to shorten the motor wires and see if that makes a difference, after that I am all out of ideas.

Yeah, weird. The only difference 12S made to the board is that it is much quieter - apart from that not a thing. No more power at all.

Hmm, only thing I can still do is to shorten the motor wires and see if that makes a difference, after that I am all out of ideas.

whitepony

10 kW

- Joined

- Feb 19, 2015

- Messages

- 663

had very little time this week and waiting for new carbon twill to do it all again anyway. I decided that I must be too stupid for coating, always some fluff or airbubble or 1 million other things that annoy me in the finished product. I deeply regret that I didnt just leave board and box in the raw state just when I unwrapped them the first time - they looked just perfect.

even though it sucks a little to do it all again, it gives me the opportunity to actually wrap the 8 M4 inserts in carbon too, also used some putty to correct the slight sag of the carbon on the motor wire channel, so the next version will be even better:

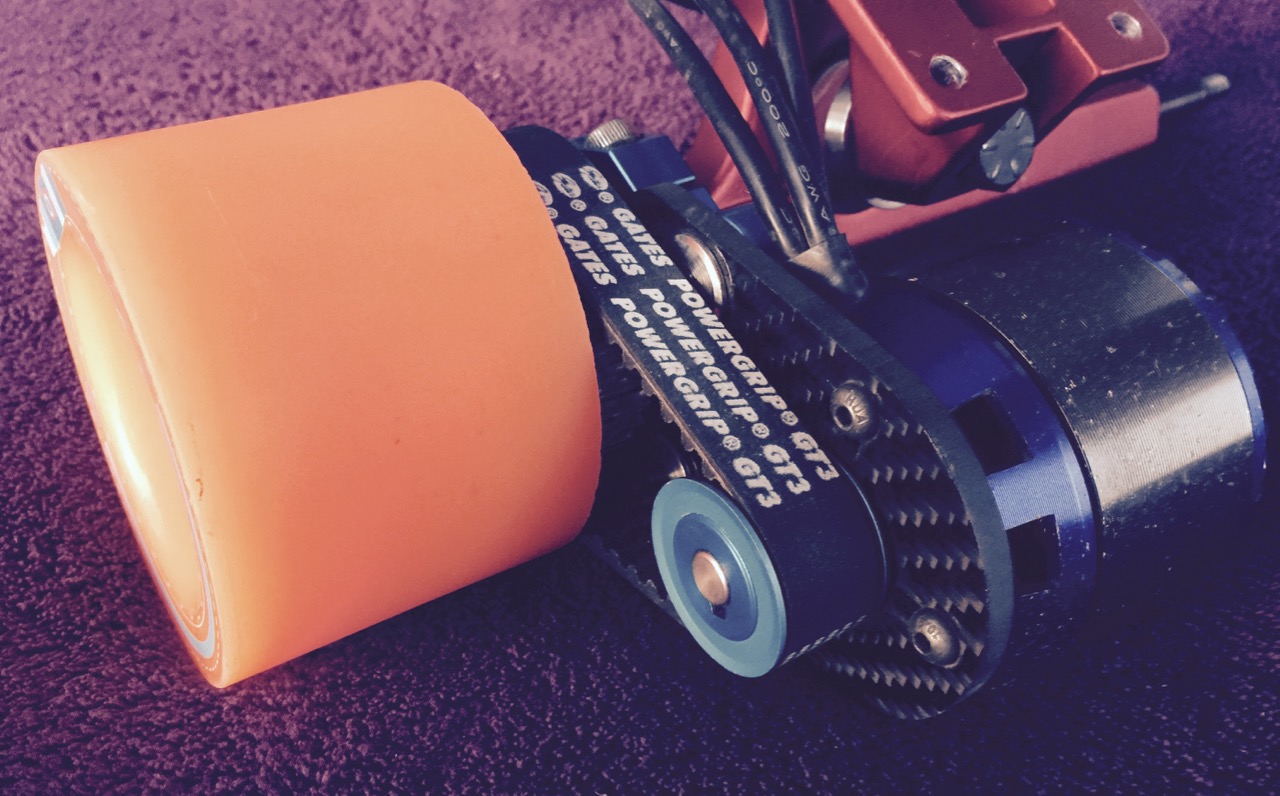

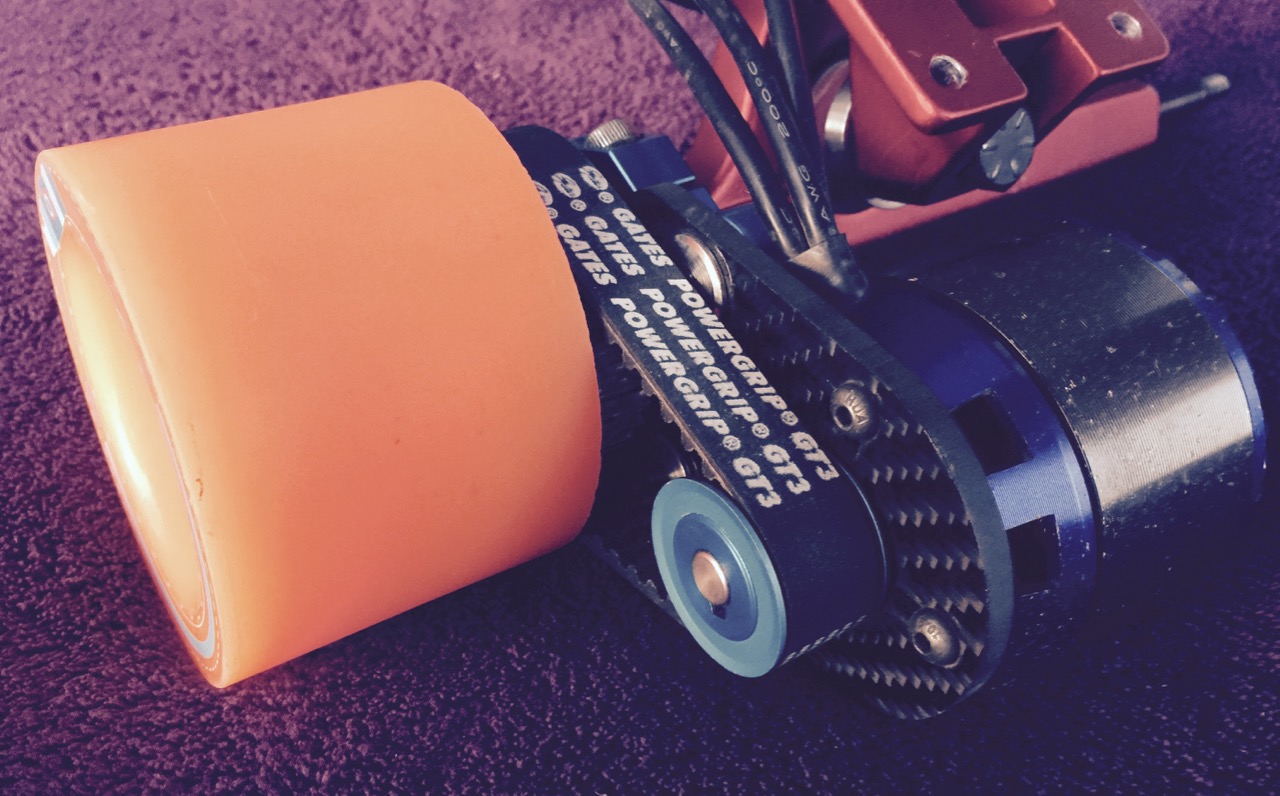

meanwhile my 15mm drive gear arrived from aliendrivesystems (still had a nicely anodized motor pulley from torqueboards). a few people can now throw a "told you so" in my face :lol: with my dual rear setup, I never had belt slip issues, with the single and a fresh belt, I didnt have much trouble with belt slip either, BUT: the older it got and the less tension it had, the more of an issue it was while breaking. must say, 15mm looks pretty smooth:

even though it sucks a little to do it all again, it gives me the opportunity to actually wrap the 8 M4 inserts in carbon too, also used some putty to correct the slight sag of the carbon on the motor wire channel, so the next version will be even better:

meanwhile my 15mm drive gear arrived from aliendrivesystems (still had a nicely anodized motor pulley from torqueboards). a few people can now throw a "told you so" in my face :lol: with my dual rear setup, I never had belt slip issues, with the single and a fresh belt, I didnt have much trouble with belt slip either, BUT: the older it got and the less tension it had, the more of an issue it was while breaking. must say, 15mm looks pretty smooth:

Hi Whitepony, Concerning your GT3 Belt,...I had called Gates Company about these belts ,and was informed these Belts are indeed superior to HTD,... BUT only when used with Gears above 18Teeth i think, had to do with the (GT3 Bend limits), I was told anything under 18T, HTD was better.

That's what a Gates employee told me????

That's what a Gates employee told me????

whitepony

10 kW

- Joined

- Feb 19, 2015

- Messages

- 663

randyc1 said:Hi Whitepony, Concerning your GT3 Belt,...I had called Gates Company about these belts ,and was informed these Belts are indeed superior to HTD,... BUT only when used with Gears above 18Teeth i think, had to do with the (GT3 Bend limits), I was told anything under 18T, HTD was better.

interesting, superior in what category though? I found gates gt3 to be super sturdy. ive lost quite a few enertion standard belts by stones that get between belt & drive wheel -> stone works itself in, belt tears in one spot, belt is a goner very soon.

with the gates belt Ive had stones working themselves in, had a superhard time removing them, but when I did, the belt just held up. so far ive never had to change a gates gt3 belt (used them on topspeed and on my evolve).

piyiotisk said:The single vs the dual drive when you accelerate or brake is there much torque steer on the single?

you notice a little bit of wobble when you change from acc to braking and vice versa, but its not bad. it strongly depends on your truck bushings of course - if you run very loose trucks, youll probably notice it more.

Similar threads

- Replies

- 106

- Views

- 38,039

- Replies

- 9

- Views

- 2,648