parajared

10 kW

So should I be worried? I was bulk charging my lipos with a 6s (or shall I say 24volt) cable at a rate of 10 amps when the charger stopped and said "connection break" I looked at the charger and the power poles were melted together!

The 18ish gauge wires that come with the charger were hot and the 10 gauge sized wire on the battery side was warm. My guess is 10 amps is too much for 18 gauge wire. If my guess is correct it seems silly to include 18 gauge charge leads with a 400 watt charger. Or could this be another problem?

Equipment used: Turnigy mega 400watt x2 charger. DPS-600PB 575 watt power supply. PA75 connector reduced from 10ga wire to 45amp anderson power poles on 18ga wire for charging.

Also I have run into other problems with andersons. They also get pretty warm if you use them as the connection between the battery and the controller. I have worried before about this connection melting, but never my charger cable connection.

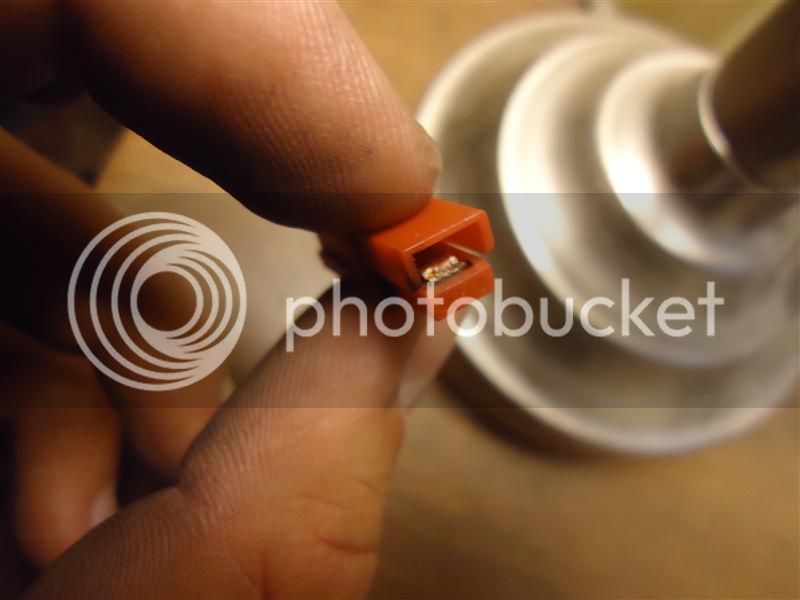

Every time I connect the battery to the controller there is a little pop of electricity. After doing this for the last five or six months the connection has slowly corroded away. I have a picture of a partially corroded power pole, and a completely corroded one. This is what has lead me to switch to PA75 connectors for this particular connection.

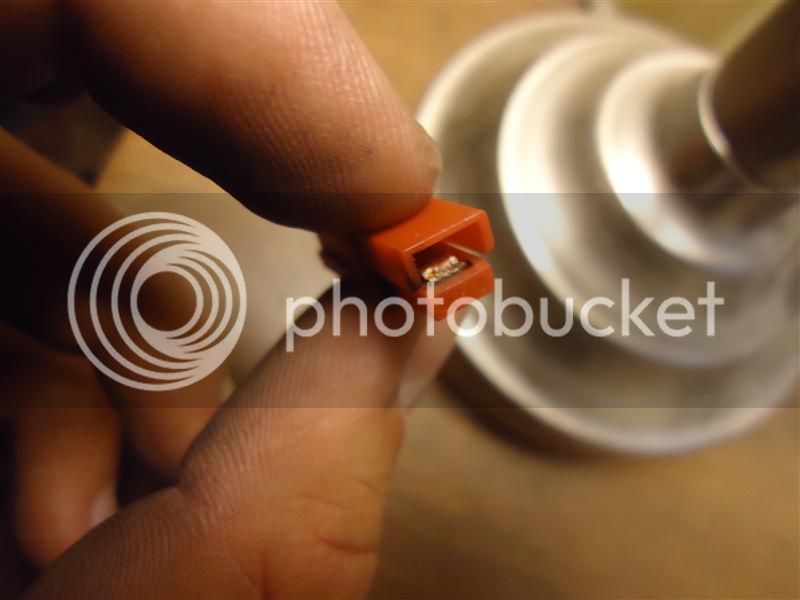

and here is a PA75 after about a month's worth of use. PA75 seems to be working so far, it seems to clean itself every time it is clicked together.

The 18ish gauge wires that come with the charger were hot and the 10 gauge sized wire on the battery side was warm. My guess is 10 amps is too much for 18 gauge wire. If my guess is correct it seems silly to include 18 gauge charge leads with a 400 watt charger. Or could this be another problem?

Equipment used: Turnigy mega 400watt x2 charger. DPS-600PB 575 watt power supply. PA75 connector reduced from 10ga wire to 45amp anderson power poles on 18ga wire for charging.

Also I have run into other problems with andersons. They also get pretty warm if you use them as the connection between the battery and the controller. I have worried before about this connection melting, but never my charger cable connection.

Every time I connect the battery to the controller there is a little pop of electricity. After doing this for the last five or six months the connection has slowly corroded away. I have a picture of a partially corroded power pole, and a completely corroded one. This is what has lead me to switch to PA75 connectors for this particular connection.

and here is a PA75 after about a month's worth of use. PA75 seems to be working so far, it seems to clean itself every time it is clicked together.