whatever

100 kW

- Joined

- Jun 3, 2010

- Messages

- 1,297

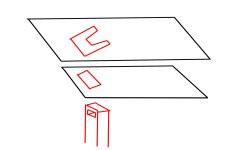

just came across a startup in brisbane, they've just recieved significant govt funding also, but the idea is cylinderical cell cases that make assembly and dissassembly quick and easy, its a very nice idea. It looks like the contacts are pressure based, heres a video might be of interest to some folks out there if it hasn't already been posted

vault battery cases

vault battery cases