tylerwatts

100 W

- Joined

- Sep 14, 2012

- Messages

- 212

Hi Tony

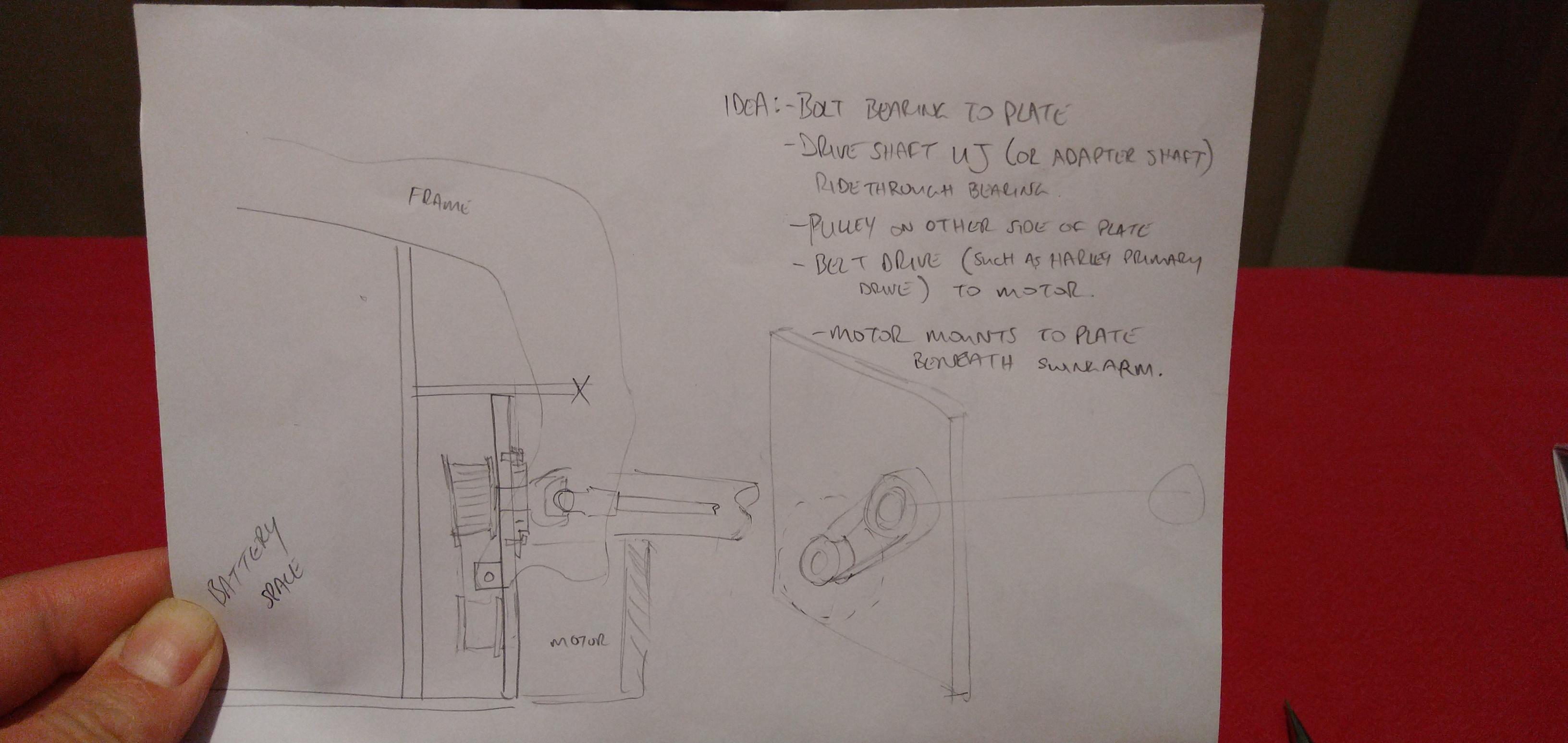

There's an opportunity to have more space by mounting the motor below and behind the shaft output with a simple belt reduction between them. Really simple setup that can be part of the battery mount cage and save weight and cost also. Just food for thought that this wouldn't cost a lot and the benefit of not using the gearbox is significant. You don't need it in an ev!

Additionally, you'd have space for more batteries in future meaning you could turn up your Sevcon to get some more performance and spice it up some. I can sketch my solution out for you if you are interested but I don't want to pressure you, just make sure you are informed. I've planned this same conversion style on a BMW K series for a while, not had funds to do it though.

Cheers

Tyler

There's an opportunity to have more space by mounting the motor below and behind the shaft output with a simple belt reduction between them. Really simple setup that can be part of the battery mount cage and save weight and cost also. Just food for thought that this wouldn't cost a lot and the benefit of not using the gearbox is significant. You don't need it in an ev!

Additionally, you'd have space for more batteries in future meaning you could turn up your Sevcon to get some more performance and spice it up some. I can sketch my solution out for you if you are interested but I don't want to pressure you, just make sure you are informed. I've planned this same conversion style on a BMW K series for a while, not had funds to do it though.

Cheers

Tyler