You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Nissan Leaf Cells Test Data

- Thread starter icecube57

- Start date

icecube57

10 MW

Someone on the facebook wanted this info

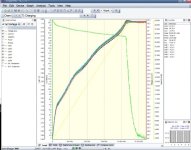

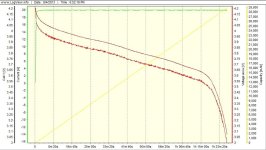

My excel data shows 27.394AH at 3.50v a cell at 3.5A.

At 20A my excel data shows 26.108AH at 3.5v a cell.

This is the AH given under load.

At the 3.5A rate there is still 2AH left on the table between 3.5v and 3.0v . I assume roughly 650-700mah to 2.75. Im not sure whats in it down to 2.5v Ill check that next I still have 12 more cells to capacity check.

My excel data shows 27.394AH at 3.50v a cell at 3.5A.

At 20A my excel data shows 26.108AH at 3.5v a cell.

This is the AH given under load.

At the 3.5A rate there is still 2AH left on the table between 3.5v and 3.0v . I assume roughly 650-700mah to 2.75. Im not sure whats in it down to 2.5v Ill check that next I still have 12 more cells to capacity check.

icecube57

10 MW

swbluto said:icecube57 said:Battery module specs[2]

Number of cells 4

Construction 2 in-series pairs in parallel

Length 11.9291" (303 mm)

Width 8.7795" (223 mm)

Thickness 1.3779" (35 mm)

Weight 8.3775 lbs (3.8 kgs)

Output terminal M6 nut

Voltage sensing terminal M4 nut

Module fixing hole diameter 0.3582" (9.1 mm)

Cell specs[2]

Cell type Laminate type

Cathode material LiMn2O4 with LiNiO2

Anode material Graphite

Rated capacity (0.3C) 33.1 Ah

Average voltage 3.8 V

Length 11.417" (290 mm)

Width 8.504" (216 mm)

Thickness 0.2795" (7.1mm)

Weight 1.7624 lbs (799 g)

That looks like 160wh/kg, just a little better than Lipo's 140wh/kg. Pretty cool. What kind of lifespan specs does this chemistry have? 300 cycles 'til 80% capacity? 1000? 2000?

I calculated 152 wh/kg i believe.

icecube57 said:swbluto said:icecube57 said:Battery module specs[2]

Number of cells 4

Construction 2 in-series pairs in parallel

Length 11.9291" (303 mm)

Width 8.7795" (223 mm)

Thickness 1.3779" (35 mm)

Weight 8.3775 lbs (3.8 kgs)

Output terminal M6 nut

Voltage sensing terminal M4 nut

Module fixing hole diameter 0.3582" (9.1 mm)

Cell specs[2]

Cell type Laminate type

Cathode material LiMn2O4 with LiNiO2

Anode material Graphite

Rated capacity (0.3C) 33.1 Ah

Average voltage 3.8 V

Length 11.417" (290 mm)

Width 8.504" (216 mm)

Thickness 0.2795" (7.1mm)

Weight 1.7624 lbs (799 g)

That looks like 160wh/kg, just a little better than Lipo's 140wh/kg. Pretty cool. What kind of lifespan specs does this chemistry have? 300 cycles 'til 80% capacity? 1000? 2000?

I calculated 152 wh/kg i believe.

I did volt*ah/weight using the cell specs.

Did your calculation differ?

icecube57

10 MW

157 at 3.8v

173 at 4.2v

173 at 4.2v

icecube57

10 MW

It turns out if you cut the copper bus properly, you do not need to split the 4 cells. You just have to be creative at the wiring job to turn it into 4s1p.

I found the hardest part was getting the aluminum case out without bending the packs.

Overall the battery is still very heavy!

I'll upload a video on how to properly disassemble and solder it to your liking.

Stay tuned!

I found the hardest part was getting the aluminum case out without bending the packs.

Overall the battery is still very heavy!

I'll upload a video on how to properly disassemble and solder it to your liking.

Stay tuned!

icecube57

10 MW

I wanted to remove all that bulk and weight and now that you mention it yeah I could have kept them together but there still would have been an issue with shielding the tabs and stuff.

My 6s pack weighs about 10lbs 12oz.

To be honest with you I may just test the sells and make a 48v 30AH pack ride it a few cycles and sell it off.

My 6s pack weighs about 10lbs 12oz.

To be honest with you I may just test the sells and make a 48v 30AH pack ride it a few cycles and sell it off.

John in CR

100 TW

Great work Icey. Regarding balancing, they may be similar enough in chemistry to Konions that they will self balance to a large extent. I just wish Nissan would change them up to 4s modules. I think they'd find a great market for their excess production capacity at their battery factory in Tennessee.

icecube57

10 MW

One thing about doing the capacity test on these cells is they are like spot on very consistent. There might be a 150mah spread at most but most have been hitting 50mah differential. I'm anal and I probably dont have to test these cells but the amount of effort it takes to separate them I'm just making sure none were damaged in the molestation process.

icecube57 said:I wanted to remove all that bulk and weight and now that you mention it yeah I could have kept them together but there still would have been an issue with shielding the tabs and stuff.

My 6s pack weighs about 10lbs 12oz.

To be honest with you I may just test the sells and make a 48v 30AH pack ride it a few cycles and sell it off.

Why would you want to sell it? Too saggy? Too heavy? Can't do high discharge?

Harold in CR

100 kW

Off topic question, if I may ??

I am looking for house batteries. A 12V system for now. Probably go to 24V later on.

These cells are figuring 3.8V per cell, correct ? That makes 4 cells @ 15.2V nominal ?? A bit too high for a 12V system, If I hook up 2 sets of cells @ 4s4p ? 3 cells make it 11.4V nominal ? That's too low.

The price is good, and I can keep the cells inside the house, in a good enclosure and quick disconnect, if there is ever an emergency issue comes along.

Anyone want to comment on my question?

Icecube, nice testing on those cells. Thanks for that. 8)

I am looking for house batteries. A 12V system for now. Probably go to 24V later on.

These cells are figuring 3.8V per cell, correct ? That makes 4 cells @ 15.2V nominal ?? A bit too high for a 12V system, If I hook up 2 sets of cells @ 4s4p ? 3 cells make it 11.4V nominal ? That's too low.

The price is good, and I can keep the cells inside the house, in a good enclosure and quick disconnect, if there is ever an emergency issue comes along.

Anyone want to comment on my question?

Icecube, nice testing on those cells. Thanks for that. 8)

SamTexas

1 MW

LiFePO4 with a nominal voltage of 3.2 to 3.3V is a perfect replacement for 12V lead acid. 4 in series for 12V, 8 in series for 24V, etc...Harold in CR said:I am looking for house batteries. A 12V system for now. Probably go to 24V later on.

These cells are figuring 3.8V per cell, correct ? That makes 4 cells @ 15.2V nominal ?? A bit too high for a 12V system, If I hook up 2 sets of cells @ 4s4p ? 3 cells make it 11.4V nominal ? That's too low.

....

Anyone want to comment on my question?

All other lithium (including this Nissan cell) has a nominal voltage of 3.6 to 3.8V and can not be used as a replacement for 12V lead acid (for the reasons you stated above, too low or too high).

However they work fine for 24V, 48V, 72V... As long as it's a multiple of 24. 7 in series for 24V, 14 in series for 48V, etc...

icecube57

10 MW

3s cells would work fine if you are willing to do the work to separate the 60AH groups. You only need 3 modules for a 115Ah setup. and it would be a true 115-120Ah not like a 100Ah AGM that only gives 60AH best.

John in CR

100 TW

What are you trying to do with 12V that isn't fine at a top of charge 16V?

999zip999

100 TW

Is this a great battery for a middrive long range trike ? Little balance 30ah. What's the charge rate ? If fast charge over 1 hr. lunch ???

icecube57

10 MW

Ive been hitting the individual cells with 30A. Im sure it could take much more considering the fast charge on the leaf is 125A roughly.

OK I went ahead and did some research on these cells since there is no good documentation on what the max continuous/burst charge/discharge specs.

So base on this website on the Nissan leaf:

http://www.mynissanleaf.com/wiki/index.php?title=Battery_specs

So here is the important stuff:

48 modules. Each modules is 7.6V60Ah roughly. Really 66Ah if we go with individual cell specs. Remember 2s2p. But we will assume 30Ah because we will be doin the math on high discharge not the 0.5C or 0.1C discharge capacity test they did.

48 modules in series gives nominal 365.4V (360V to round). Or 403.2V Max. I would use nominal to calculate things.

The battery is rated for up to 90KW discharge. I am assuming this is continuous because the motor is rated at 80KW so this pack should be able to handle 90KW continuous. This is a big assumption, but without, I cannot calculate anything.

90000W/403V = 223A continuous. I am using Max voltage to leave headroom for calculation.

223A/60Ah ~= 3.7C

So saying these cells are 3C continuous would be a good estimate base on the assumption.

If most people build batteries using these cells, you can expect at least 90A continuous current draw from these packs if you make 4s1p. I suspect if you keep it to 2C or 60A current draw from these cells, the voltage sag shouldn't be a problem. Maybe near end of life of these cells will you notice the problem,but then again this is true for ALL lithium batteries including HK lipo.

For my ebike, I never go over 50A anyways, so these pack would serve me well. Again this is expected. Keep in mind, these are not your typical HK lipo cells with 25C discharge capacity. So you should not expect them to work that way. I would say these are more for safe, long range, reasonable power cells.

The website also states:

Power density: 2.5KW/kg.

Cell weight: 0.8Kg

2.5KW/kg * 0.8kg = 2KW.

2KW/4.2V = 476A from ONE cell. Each cell is 30Ah

476A/30Ah ~= 15.9C or 16C. But lets say it's 15C

I believe this is the upper limit. Meaning 15C is the max discharge rate of these cells.

As for charging capacity, here is what everyone knows. The pack is capable of the High current recharge. Nissan Claims 80% charge from empty in 30 minutes. These charger are 50KW charger.

50000/403V = 124A

124A/60Ah ~= 2C

But Nissan warns you will loss capacity if you charge this fast often. Therefore, I suspect charging should be kept at 1C or 30A to prolong battery life. In fact, I would recommend 0.5C or 15A charging at most. Most cells behave well when charge at 0.5C. Moreover, if you build high power pack like me 20s or 24s, it is hard to charge even at 15A here in the USA with 1500W circuit breaker.

So base on this website on the Nissan leaf:

http://www.mynissanleaf.com/wiki/index.php?title=Battery_specs

So here is the important stuff:

48 modules. Each modules is 7.6V60Ah roughly. Really 66Ah if we go with individual cell specs. Remember 2s2p. But we will assume 30Ah because we will be doin the math on high discharge not the 0.5C or 0.1C discharge capacity test they did.

48 modules in series gives nominal 365.4V (360V to round). Or 403.2V Max. I would use nominal to calculate things.

The battery is rated for up to 90KW discharge. I am assuming this is continuous because the motor is rated at 80KW so this pack should be able to handle 90KW continuous. This is a big assumption, but without, I cannot calculate anything.

90000W/403V = 223A continuous. I am using Max voltage to leave headroom for calculation.

223A/60Ah ~= 3.7C

So saying these cells are 3C continuous would be a good estimate base on the assumption.

If most people build batteries using these cells, you can expect at least 90A continuous current draw from these packs if you make 4s1p. I suspect if you keep it to 2C or 60A current draw from these cells, the voltage sag shouldn't be a problem. Maybe near end of life of these cells will you notice the problem,but then again this is true for ALL lithium batteries including HK lipo.

For my ebike, I never go over 50A anyways, so these pack would serve me well. Again this is expected. Keep in mind, these are not your typical HK lipo cells with 25C discharge capacity. So you should not expect them to work that way. I would say these are more for safe, long range, reasonable power cells.

The website also states:

Power density: 2.5KW/kg.

Cell weight: 0.8Kg

2.5KW/kg * 0.8kg = 2KW.

2KW/4.2V = 476A from ONE cell. Each cell is 30Ah

476A/30Ah ~= 15.9C or 16C. But lets say it's 15C

I believe this is the upper limit. Meaning 15C is the max discharge rate of these cells.

As for charging capacity, here is what everyone knows. The pack is capable of the High current recharge. Nissan Claims 80% charge from empty in 30 minutes. These charger are 50KW charger.

50000/403V = 124A

124A/60Ah ~= 2C

But Nissan warns you will loss capacity if you charge this fast often. Therefore, I suspect charging should be kept at 1C or 30A to prolong battery life. In fact, I would recommend 0.5C or 15A charging at most. Most cells behave well when charge at 0.5C. Moreover, if you build high power pack like me 20s or 24s, it is hard to charge even at 15A here in the USA with 1500W circuit breaker.

SamTexas

1 MW

I did not discuss remaining capacity. I was talking about the high voltage sag, even at a very low discharge rate. I was also talking about low energy density at original capacity when compared to the newest Panasonic 18650 cells.Hillhater said:Well , actually what you see is a USED battery from a Nissan Leaf..... that has been used for many 100's of its cycle life expectancy.SamTexas said:What I see is a battery from a Nissan Leaf, a relatively new car in the market.

Which is why you would not expect it to still have its original Ahr capacity.

I am also surprised at the very low discharge (C) rate these are rated at !

Judging from the 0.6C discharge graph, I wonder if this cell can be discharged at 2C continuously at all.

SamTexas

1 MW

icecube: I looked again at your CAM00556 picture. Unless I'm mistaken, you did not have the sense wires attached. So your discharge graph was not showing the true cell voltage. Instead it was showing the cell voltage minus the voltage drop across the main leads. This might explain why the sag was so bad. Voltage drop at 20A is significant even over a short distance.

icecube57

10 MW

I don't think there is a such thing as a 1s balance connector for me to connect the sense leads to the Icharger. Most single cell charging scenario only have the main leads no separate sense wires. I believe the 20A test data to be accurate as possible. The leads are soldered directly to the tabs and 4mm bullets attached to the output of the charger. I will gladly hack up a 6s cable and make it to where the sense wires are added and redo the discharge test but i believe the results will be the same or so minute that we would have to discard it.

SamTexas

1 MW

Yep, unfortunately these chargers were never designed for 1S.

No need to redo the full test. Here a quick test to determine the voltage drop across those two short lead wires at 20A: Briefly rerun this 20A test, no need to start from a full charge cell. Use a voltmeter to measure the voltage at the cell terminals, compare that voltage to the one measured at the 4mm bullets attached to the charger. What's the delta?

Or set the voltmeter to mV and check the voltage between the negative 4mm bullet and the cell negative terminal.

Whatever the delta is, your 0.6C discharge graph can be raised up by that much. I'm guessing somewhere between 0.2 and 0.5V.

No need to redo the full test. Here a quick test to determine the voltage drop across those two short lead wires at 20A: Briefly rerun this 20A test, no need to start from a full charge cell. Use a voltmeter to measure the voltage at the cell terminals, compare that voltage to the one measured at the 4mm bullets attached to the charger. What's the delta?

Or set the voltmeter to mV and check the voltage between the negative 4mm bullet and the cell negative terminal.

Whatever the delta is, your 0.6C discharge graph can be raised up by that much. I'm guessing somewhere between 0.2 and 0.5V.

icecube57

10 MW

Well indeed there is a different set of readings atleast with me charging the cell. Im charging the cell and logview is giving me the actual cell voltage and and output voltage which has a spread of about .12-13mv. Also instead of it giving me 6mohm when it checks the cell IR it gives me 0-1. I still got cells to test so ill give an updated discharge and post back here.

Attachments

icecube57

10 MW

Similar threads

- Replies

- 0

- Views

- 481

- Replies

- 5

- Views

- 444

- Replies

- 4

- Views

- 211