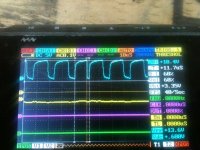

OK so I have to get a tri pod lol. I tried realy hard to get an explosion on video for you all lol. I tested for about 1 hour till I had the controller starting smoth on its own at 8v which is what I was doing all my testing at to start with. I scoped all the Low and hi side gates to source and found they were not bad in fact the HI side was clean as I think it can be. It was charging to 11.2v and was a realy clean square wave. The low side was not as clean but its hard to read because I upped the PWM to 50khz. I changed the milisec to .1 instead of 1 and that was the biggest thing to make it start with out me spining the motor. All and all great progress today realy good. I realy have a lot to learn about the code and I need to put a switch on my controller and set up the throttle so it scales. And the board doesnt want to start as soon as I turn it on. BTW I think what killed it was the ground wire that supplie the low side fet driver slipping off the aligator clip damb I forgot I wanted to solder that lol.

[youtube]wvnUW37oXLo[/youtube]

[youtube]wvnUW37oXLo[/youtube]