offGridDownUnder

1 kW

My Greenspeed Magnum seat is welded aluminium tubing - two bent side rails connected with three cross rails. I need to duplicate it with some changes.

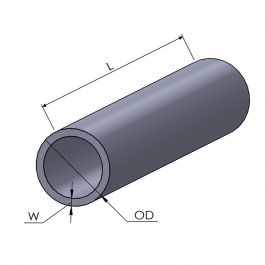

The tubing is 25mm OD and 2.5mm wall thickness - so 1" and 0.1" thick. The middle cross rail must be removed, so some change to stiffen the side rails is needed - larger OD, thicker wall, or double rails on each side welded together after bending into shape. The only purpose of that middle cross rail is to prevent the sides from bending inward. The seat cover is a mesh tube laced on with elastic cord, so very forgiving of modest changes to tubing size.

Heat treating isn't commonly available here outside of industrial batches, so I want material that doesn't require it, but can be welded. It's likely 6061 now, but that and 7075 are out due to the need to heat treat after fabrication.

I understand Al 5083 or 5052 will do, as will many steels. As it will be rained on, and painting the inside of the tubing isn't easy, I lean towards the Al, but happy to hear if you know a way to ensure steel won't corrode from the inside that I can afford for a one-off build.

I'd like a source to buy aluminium tubing to those specifications - can anyone tell me a reliable seller for small quantities of 5083 or 5052 tubing? 4 to 10 meters (as I may use some more for a framework to mount a roof on the trike).

Open to information about steel as well.

The tubing is 25mm OD and 2.5mm wall thickness - so 1" and 0.1" thick. The middle cross rail must be removed, so some change to stiffen the side rails is needed - larger OD, thicker wall, or double rails on each side welded together after bending into shape. The only purpose of that middle cross rail is to prevent the sides from bending inward. The seat cover is a mesh tube laced on with elastic cord, so very forgiving of modest changes to tubing size.

Heat treating isn't commonly available here outside of industrial batches, so I want material that doesn't require it, but can be welded. It's likely 6061 now, but that and 7075 are out due to the need to heat treat after fabrication.

I understand Al 5083 or 5052 will do, as will many steels. As it will be rained on, and painting the inside of the tubing isn't easy, I lean towards the Al, but happy to hear if you know a way to ensure steel won't corrode from the inside that I can afford for a one-off build.

I'd like a source to buy aluminium tubing to those specifications - can anyone tell me a reliable seller for small quantities of 5083 or 5052 tubing? 4 to 10 meters (as I may use some more for a framework to mount a roof on the trike).

Open to information about steel as well.