jimmyhackers

10 kW

- Joined

- May 11, 2015

- Messages

- 603

I get that a lower resistance value is better in both scenarios, but are they equal in detriment to performance?

So i ask, is 2mohm of resistance in the main battery wiring loom going to generate the equvalent detriment (voltage sag) as 2mohm of internal resistance inside that lithium battery?

just wondering if upping my cable AWG again might eek out a bit more performance/efficiency/range?

i previously went from 14awg and xt60s to 10awg and xt90s. but i could get some 8awg or 6awg even.

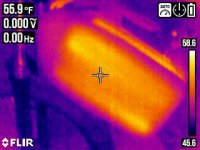

im running 3x 6s 20ah eig cell packs in series for 72v. no bms.

the loom attaches to the controller with one main xt90 and branches off 3 ways to three xt90 connectors for each of the three 6s batts

there is roughly about 0.5m of paired loom wire. and roughly 6-7cm of paired wire on each battery.

Also, Im using the xt90 anti-spark variants now, does anyone know if the reduced contact area of one pin effects thier performance compared to thier vanilla variety?

So i ask, is 2mohm of resistance in the main battery wiring loom going to generate the equvalent detriment (voltage sag) as 2mohm of internal resistance inside that lithium battery?

just wondering if upping my cable AWG again might eek out a bit more performance/efficiency/range?

i previously went from 14awg and xt60s to 10awg and xt90s. but i could get some 8awg or 6awg even.

im running 3x 6s 20ah eig cell packs in series for 72v. no bms.

the loom attaches to the controller with one main xt90 and branches off 3 ways to three xt90 connectors for each of the three 6s batts

there is roughly about 0.5m of paired loom wire. and roughly 6-7cm of paired wire on each battery.

Also, Im using the xt90 anti-spark variants now, does anyone know if the reduced contact area of one pin effects thier performance compared to thier vanilla variety?

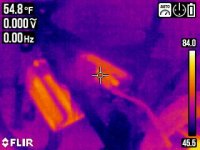

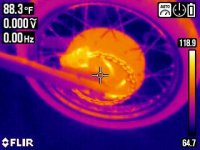

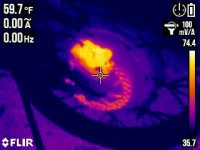

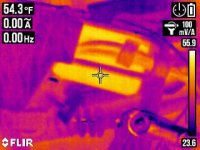

![20230328_151215[1].jpg 20230328_151215[1].jpg](https://endless-sphere.com/sphere/data/attachments/192/192887-3bd85cd9b23d78768b80ac20e293436a.jpg)