Kepler

10 MW

jateureka said:Kepler, do you know what date code BBS02 had the O-ring groove?

Is this O-ring issue just with the BBS02 or did it happen on early BBS01 versions as well?

Great info!

Unfortunately I can't give you a definitive answer on this one. Date on mine is 2/12/2013 and definitely didn't have an O ring on the non drive side. It was also marked BBS01 48V 750W

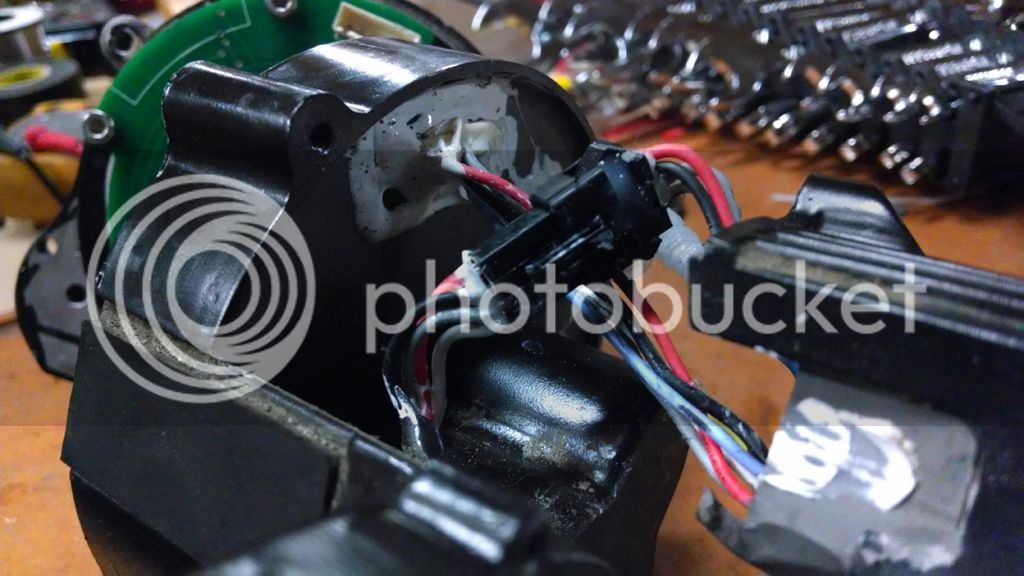

I have new drive in stock which is marked BBS02 48V 750W and the date of manufacture is 27/02/2014. I haven't opened it up though to check the O ring. The rotor I have pictured is a spare part that I managed to get through my supplier to replace my worn one. However, the original rotor is still in my drive with the shaft loctited to the bearing and running as quiet as the day I installed it.

Just on the parts replacement issue.

Although Bafang do need a bit of prodding, if you can put together a convincing case about the failure including photos and a logical explanation, there is a good chance you will get the part replaced. We have had one local case whereby a stator burnt out. The failure was clearly a manufacturing fault which we demonstrated with good photographic evidence. Bafang came to the party with the the help of the supplier (Amy) and sent out a replacement stator assembly. This dive has been work perfectly ever since.