tomjasz

1 GW

From Doug in my archives.

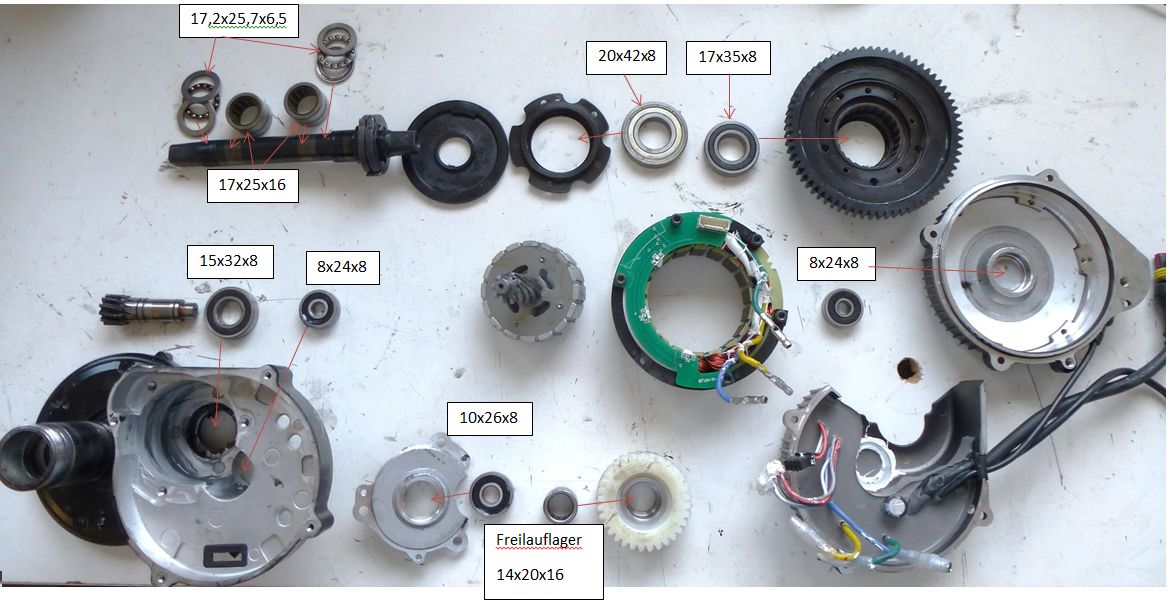

All bearings should be clearly marked as to industry standard numbering. So when you tear down a motor, any bearing that is suspect of damage can be replaced from local sources using the bearing number written on the bearing. One exception is the ball thrust bearings which are proprietary to Bafang. I've never been able to source these bearings elsewhere.

Here is what I have for the moment.

motor

2 motor shaft bearings These will be 628 bearings on both ends unless you have the latest version with the heavier rotor shaft. Then one of the bearings will be a 629 bearing.

Gears

1 bearing in the steel gear cover

1 pinion pressed-in case bearing

1 nylon gear/pinion cover plate bearing 16001

Nylon gear (built-in) needle bearing This is a clutch bearing HFL1626

Axle

1 44mm axle bearing

1 axle needle bearing NK17/16

1 three-piece roller (or thrust) bearing Nonstandard proprietary to Bafang

I hope this helps. We do not have any HD's open for repair at the moment so I have not been able to get more information.

All bearings should be clearly marked as to industry standard numbering. So when you tear down a motor, any bearing that is suspect of damage can be replaced from local sources using the bearing number written on the bearing. One exception is the ball thrust bearings which are proprietary to Bafang. I've never been able to source these bearings elsewhere.

Here is what I have for the moment.

motor

2 motor shaft bearings These will be 628 bearings on both ends unless you have the latest version with the heavier rotor shaft. Then one of the bearings will be a 629 bearing.

Gears

1 bearing in the steel gear cover

1 pinion pressed-in case bearing

1 nylon gear/pinion cover plate bearing 16001

Nylon gear (built-in) needle bearing This is a clutch bearing HFL1626

Axle

1 44mm axle bearing

1 axle needle bearing NK17/16

1 three-piece roller (or thrust) bearing Nonstandard proprietary to Bafang

I hope this helps. We do not have any HD's open for repair at the moment so I have not been able to get more information.

![mittelmotor[1].jpg](/sphere/data/attachments/186/186347-7fab695504849769a5418b87c33bb5f9.jpg)