Skippic

100 W

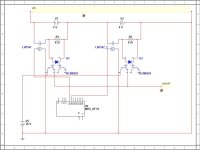

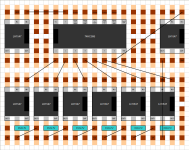

My intention is to make an Arduino driven BMS. This is for a 24s LiPo pack. The idea is to use a multiplexer to turn on a solid state relay at each cell connected in series with a resistor and an analog optocoupler (in parallel).

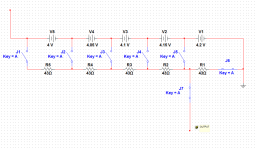

It should work by checking the voltages once every minute (while charging or in use), if it detects a cell below 3.6V it sends LVC signal.

If the pack is charging and the max voltage is more then 4V and a cell is 0.1V above the lowest cell it discharges the highest cell for one minute.

I need help selecting the most suitable components. At the moment the best solid state relay I found is the LH1547 at about $0.90 a piece shipping included. It's max current rating is 120mA (a little low). But since it will be balancing every charge and I will use a charger of my own making, so the BMS can turn it on and off as many times as I like to get the pack balanced and fully charged it should be OK.

My biggest problem is searching for analog optocouplers. I've been able to find the HCNR201 at $3.10 each. That's $74.40 for optocouplers! Is there a cheaper analog optocoupler? It doesn't need to be perfectly linear, just give consistent output values at the same input for all the cells.

Just to avoid multiple posts: yes I'm using the same circuit for measuring and discharging the cells. The difference is, that for measuring all that is needed is a few ms, while for discharging it's in order of minutes or hours.

I'm also thinking of placing a small capacitor in series with the optocoupler, so it doesn't burn the LED when discharging.

Originally the idea was to use a separate MUX for reading the opto values, but maybe I can use them connected with common output or at least through resistors with reduced sensitivity. Can someone tell me what is the best solution here?

It should work by checking the voltages once every minute (while charging or in use), if it detects a cell below 3.6V it sends LVC signal.

If the pack is charging and the max voltage is more then 4V and a cell is 0.1V above the lowest cell it discharges the highest cell for one minute.

I need help selecting the most suitable components. At the moment the best solid state relay I found is the LH1547 at about $0.90 a piece shipping included. It's max current rating is 120mA (a little low). But since it will be balancing every charge and I will use a charger of my own making, so the BMS can turn it on and off as many times as I like to get the pack balanced and fully charged it should be OK.

My biggest problem is searching for analog optocouplers. I've been able to find the HCNR201 at $3.10 each. That's $74.40 for optocouplers! Is there a cheaper analog optocoupler? It doesn't need to be perfectly linear, just give consistent output values at the same input for all the cells.

Just to avoid multiple posts: yes I'm using the same circuit for measuring and discharging the cells. The difference is, that for measuring all that is needed is a few ms, while for discharging it's in order of minutes or hours.

I'm also thinking of placing a small capacitor in series with the optocoupler, so it doesn't burn the LED when discharging.

Originally the idea was to use a separate MUX for reading the opto values, but maybe I can use them connected with common output or at least through resistors with reduced sensitivity. Can someone tell me what is the best solution here?