crossbreak

1 MW

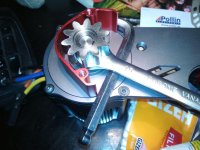

It should work with any disc brake caliper that is shimano/magura/tektro compatible. Not sure if all calipers will fit in the end, this is something to be tried. I'll cut the adapter next week and test fit it with the shimano, magura and tektro brakes i have at hand and let you know the results. I will also make a drawing that shows the max dimensions so you can check dimensions of your caliper.ScooterMan101 said:[...] For those of who already have brakes it would be good do know what dimensions of caliper would work with your rotor/cog set up, to see if our existing brakes would work or not. [...]

the ones that i have at hand all fit, i have four different brands. i will test fit this as well. We will see how it works out, it's always better to test this in the real world as there might be clearance issues that are not covered in CAD models that are always limited in precision.ScooterMan101 said:[...]

Am I reading right that your adapter for Disc Rotor and Rear Cog will fit on any Stock Wheel ?

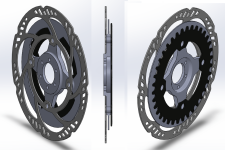

yes, as i wrote in the first post, the custom 203mm disc is included. I can send you the DXF-file of the disc rotor so you can lazer replacements at your local lazer shop. It shall be cut from 2mm 1.4021 or 1.4571 steel. If you have problems finding a lazer shop that cuts this material, there are online shops who lazer you any disc rotor you like - even with your name on it. Just send them a DXF-file, for example this shop: https://shop.brake-stuff.de/en/custom-brake-discs/30/custom-brake-disc-personalized-brake-disc-6-hole-suitable-for-downhill-bikesGrantmac said:So in the event I need a replacement disk there won't be anything off the shelf? If I understand correctly.

I dont want anyone to come short in replacement parts and dont plan to make profit from this, i just want to have better ebikes and make my own builds cheaper due to the larger number of interchangeable components. Hopefully other builders who do not use this particular motor will also use this (then) well tested left-hand drive disc/sprocket solution

Approximate price?

i said 100€ but it looks more like 150€ with all bolts and disc included. As said, the more we cut, the cheaper it gets. I pay €250 for my first prototype cuts. Without any bolts.

the adapter will add ~300g (around 0,7 lbs) of weigth to the rear wheel

for the better understanding, here is a drawing of a single piece milled adapter that will actually never be milled ( much too expensive ):