You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

EV-1 Conversion

- Thread starter JCG

- Start date

Hillhater

100 TW

I am sure they can afford any battery they can find.

.. which ones would you think !??

It is known that Ferrari use SAFT cells, but i dont know of any commercial (or military) cells from SAFT that compare to the Nanotech performance.We know there are better technologies developing, but are they actually use-able yet ?

There is a reason most teams are stuck with 20kg battery packs . :wink:

The Williams "flywheel Battery" has some real advantages in this area.

.. which ones would you think !??

It is known that Ferrari use SAFT cells, but i dont know of any commercial (or military) cells from SAFT that compare to the Nanotech performance.We know there are better technologies developing, but are they actually use-able yet ?

There is a reason most teams are stuck with 20kg battery packs . :wink:

The Williams "flywheel Battery" has some real advantages in this area.

GCinDC

100 MW

vanilla ice

1 MW

Hillhater

100 TW

Vanilla .. see reply over on the KERS thread. http://endless-sphere.com/forums/viewtopic.php?f=14&t=26380

JCG

100 W

- Joined

- Nov 10, 2008

- Messages

- 174

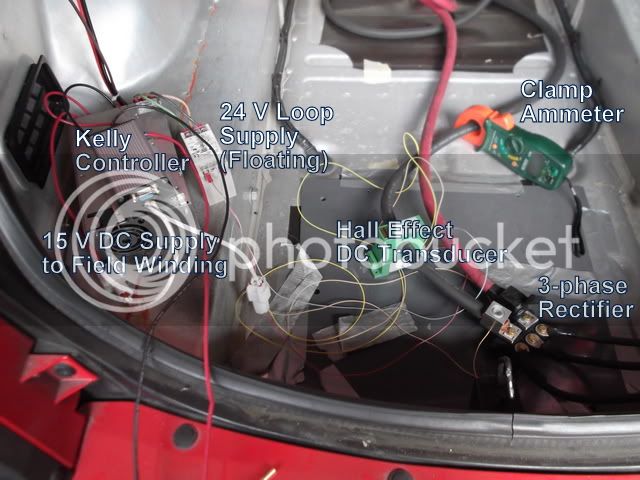

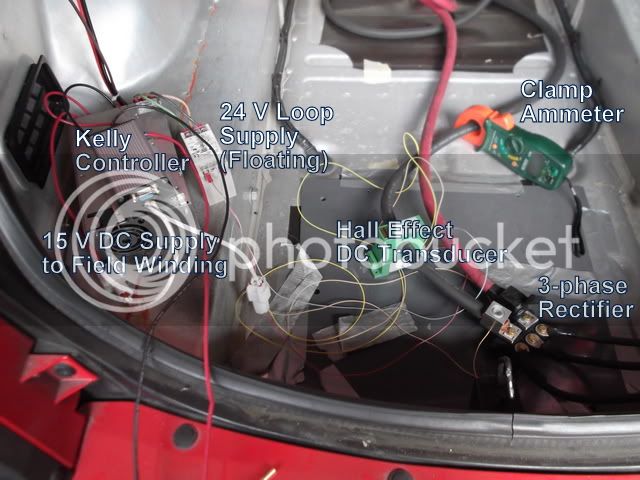

Did some work today worthy of a minor update. First of all, the current-controlled charging system works, but needs to be tweaked to make sure it's set to the right maximum excitation voltage. I'll do that part tomorrow. For now, here's the test hookup in the trunk:

That's essentially the same setup as in the schematic I posted a few weeks ago, except that I went to the DC side with a hall effect transducer. The upside is that it's receiving a much less noisy signal than the AC side of the rectifier would have provided, but the downside is that it required the 24 V supply to run it. I use the 0-5 V signal that it provides, which floats relative to the motor controller's supply, to "throttle" the motor controller's current supply to the exciter winding on the generator head. I tested it, and the charging current now never exceeds 30 A DC. I have to program the controller for its maximum supply voltage to make sure that maximum excitation is exactly right. Again, that's a job for tomorrow.

The main job of the day was to get cooling set up for the trunk. Both the gen head and the engine are air cooled, and that little space will get hot unless it's actively ventilated. I'm not sure if I ever posted a photo of the area behind the seats, so here's one with some labels:

The idea is to use these two 600 scfm fans. I estimate that they'll turn over the trunk air volume twice every three seconds or so with cool air from the cabin, which should work well. They only pull about 80 W each.

The problem is that the blades are about 8.5 inches in diameter, so I had to use a large hole saw with an arbor. The drill needed to be one with a half inch chuck, so I got this beast. Today, it had the last laugh.

Here are the pilot holes and the finished holes.

I didn't realize it when I took that last picture, but I had been injured. While cutting the last hole, the blades got gummed up in the sheet metal and the drill jerked/kicked back at me when it was going near full speed. My arms got jerked clockwise really quickly, and my left elbow hammered down on the ridge just below the holes, which was carpeted. I thought I just nailed my funny bone and waited to get feeling back in my left little and ring fingers before finishing the hole. When I put the camera down, I felt something wet on my side. Showed up well on a white t-shirt.

Turns out the carpeting tore open a hole just above my elbow. Tough picture to take, but here it is.

Looked like it needed stitches, so I went to the Emergency Room at Howard University Hospital. For those reading from outside of the United States, Emergency Rooms are where Americans like to go to wait around for several hours while bleeding to death. After about 3 hours of waiting I got some of that new glue-type sealing on the wound and a tetanus shot (which took all of five minutes) and I went back to finish the job. Here's a video of the fans firing up once the inverter is turned on. They really move the air through.

[youtube]Prp4khgKnRI[/youtube]

Anyway, more work on the current control setup tomorrow, then hope to load the whole genset into the trunk on Wednesday if I can get Chris to come help again.

That's essentially the same setup as in the schematic I posted a few weeks ago, except that I went to the DC side with a hall effect transducer. The upside is that it's receiving a much less noisy signal than the AC side of the rectifier would have provided, but the downside is that it required the 24 V supply to run it. I use the 0-5 V signal that it provides, which floats relative to the motor controller's supply, to "throttle" the motor controller's current supply to the exciter winding on the generator head. I tested it, and the charging current now never exceeds 30 A DC. I have to program the controller for its maximum supply voltage to make sure that maximum excitation is exactly right. Again, that's a job for tomorrow.

The main job of the day was to get cooling set up for the trunk. Both the gen head and the engine are air cooled, and that little space will get hot unless it's actively ventilated. I'm not sure if I ever posted a photo of the area behind the seats, so here's one with some labels:

The idea is to use these two 600 scfm fans. I estimate that they'll turn over the trunk air volume twice every three seconds or so with cool air from the cabin, which should work well. They only pull about 80 W each.

The problem is that the blades are about 8.5 inches in diameter, so I had to use a large hole saw with an arbor. The drill needed to be one with a half inch chuck, so I got this beast. Today, it had the last laugh.

Here are the pilot holes and the finished holes.

I didn't realize it when I took that last picture, but I had been injured. While cutting the last hole, the blades got gummed up in the sheet metal and the drill jerked/kicked back at me when it was going near full speed. My arms got jerked clockwise really quickly, and my left elbow hammered down on the ridge just below the holes, which was carpeted. I thought I just nailed my funny bone and waited to get feeling back in my left little and ring fingers before finishing the hole. When I put the camera down, I felt something wet on my side. Showed up well on a white t-shirt.

Turns out the carpeting tore open a hole just above my elbow. Tough picture to take, but here it is.

Looked like it needed stitches, so I went to the Emergency Room at Howard University Hospital. For those reading from outside of the United States, Emergency Rooms are where Americans like to go to wait around for several hours while bleeding to death. After about 3 hours of waiting I got some of that new glue-type sealing on the wound and a tetanus shot (which took all of five minutes) and I went back to finish the job. Here's a video of the fans firing up once the inverter is turned on. They really move the air through.

[youtube]Prp4khgKnRI[/youtube]

Anyway, more work on the current control setup tomorrow, then hope to load the whole genset into the trunk on Wednesday if I can get Chris to come help again.

paultrafalgar

10 kW

Hey Jason,

You should have put those fans on the back side of the boot(trunk). Then instead of sucking the back seat passengers into the trunk you would have had electric jet-assist!

You should have put those fans on the back side of the boot(trunk). Then instead of sucking the back seat passengers into the trunk you would have had electric jet-assist!

JCG

100 W

- Joined

- Nov 10, 2008

- Messages

- 174

paultrafalgar said:Hey Jason,

You should have put those fans on the back side of the boot(trunk). Then instead of sucking the back seat passengers into the trunk you would have had electric jet-assist!

Now you're talking, Paul. I was thinking with the fans, LEDs on the dashboard, etc. that I might as well finish what Doc Brown started... let me know if you have an extra Mr. Fusion!

TylerDurden

100 GW

Those fans are a hoot.

I would suggest radials tho, good flow, less noise.

I would suggest radials tho, good flow, less noise.

JCG

100 W

- Joined

- Nov 10, 2008

- Messages

- 174

TylerDurden said:Those fans are a hoot.I would suggest radials tho, good flow, less noise.

Hey TD, good to hear from you. I had considered radials, but couldn't get the flow rate I needed in a small package. As long as you can keep the pressure drop relatively low, axial fans are the way to go for high flow rates, although they are a bit more noisy.

Weird thing is, and maybe this is common, but the fans sound a lot noisier (more of a hum) on the video than they did in person. I think that the camera mic is more sensitive than the human eardrum for those frequencies...

Cleared out the wiring, etc. from the trunk (boot!) and have put down a rubber liner on its floor. Chris and I will try to cram the genset inside tonight using the hoist and a bit of elbow grease.

lesdit

100 W

Not sure if you mentioned yet, but what would be the overall goal of this project ?

Do you have some calculated estimates for range on with caps, and speed of 'limp home' mode when they are below your controllers LVC ?

Do you have some calculated estimates for range on with caps, and speed of 'limp home' mode when they are below your controllers LVC ?

JCG

100 W

- Joined

- Nov 10, 2008

- Messages

- 174

I think that without the genset you basically go 1 mile and then limp the mile back... and that 's on flat road.

Anyway, long night but a good night tonight. Here's the latest.

Last week Chris and I tried to cram the genset skid into the trunk and basically hit a brick wall progress-wise. Tonight, after planning over last weekend, we had much better luck.

The first step, which I actually did last week, was to put down a relatively thin (3/16" thickness) polyurethane sheet that was cut to size on the trunk floor. This was to help dampen vibration and to give the genset something squishy and grippy to sink into.

The generator head goes in first, with the engine to be positioned at the rear of the car for easy access. That's tough, because the generator head is way heavier than the engine. In fact, to move the skid around, one of us would work the hoist to raise the gen head while the other hefted the engine by hand to keep things in balance. It was a good workout.

I covered the skid end on the generator side with Teflon "footies" to help the unit slide forward.

The problem in inserting the set into the trunk came when the throttle body was blocking any effort to push the set further in, so that the engine could drop down. Note, this is after the muffler was removed to give more room to slide forward.

This was where we hit a dead end last week. What needed to occur was raising the generator head (already deep in the trunk) nearly up to the roof of the trunk, so that the engine could drop forward and down. The problem was that the head weighs 80 kg and there was no way to get to it.

So, we used a wire rope around the generator head body, put a steel channel strut through the loops, and used to scissor jacks to lift it basket-style all the way up.

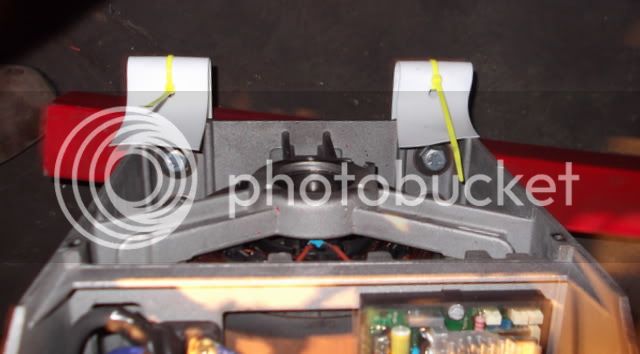

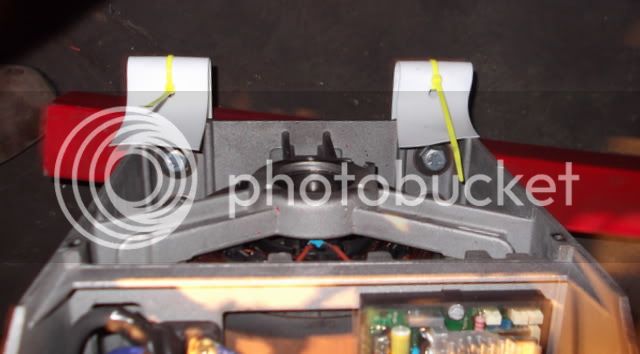

We brought it up to the ceiling, and scooted the jacks forward (while loaded) to drop the engine in. We had to take the face plate off the fan, but it went in.

Keep in mind, this was a tight fit. It was worse than a square peg-round hole, childbirth, or trying to get that big couch into your apartment when your front door is on a tight staircase. Here's a view from the top.

How did we do that?! And there was no room to fool around with. Here's an idea of how close the gen head is to the cabin wall. Things did fit nicely in the end, though. The fans are not obstructed.

I didn't even plan on this part working.

[youtube]55-eqVZA1S0[/youtube]

Granted, we had to take out the trunk latch to get the engine in, and it has to stay cracked (for now) to keep the air flowing, but closing it up was a nice touch. Also, although it's not clear from the photos, the muffler is back in place. I'll tie the exhaust line in when I get a chance.

Now all that remains is to tweak the current controlled charging setup, mount the various items for operation (connect to auxiliary battery to start, mount laser for tachometer, fuel tank, starter switch, and throttle knob). For now, I'll send an update to our wonderful project sponsor. They'll be so proud.

Anyway, long night but a good night tonight. Here's the latest.

Last week Chris and I tried to cram the genset skid into the trunk and basically hit a brick wall progress-wise. Tonight, after planning over last weekend, we had much better luck.

The first step, which I actually did last week, was to put down a relatively thin (3/16" thickness) polyurethane sheet that was cut to size on the trunk floor. This was to help dampen vibration and to give the genset something squishy and grippy to sink into.

The generator head goes in first, with the engine to be positioned at the rear of the car for easy access. That's tough, because the generator head is way heavier than the engine. In fact, to move the skid around, one of us would work the hoist to raise the gen head while the other hefted the engine by hand to keep things in balance. It was a good workout.

I covered the skid end on the generator side with Teflon "footies" to help the unit slide forward.

The problem in inserting the set into the trunk came when the throttle body was blocking any effort to push the set further in, so that the engine could drop down. Note, this is after the muffler was removed to give more room to slide forward.

This was where we hit a dead end last week. What needed to occur was raising the generator head (already deep in the trunk) nearly up to the roof of the trunk, so that the engine could drop forward and down. The problem was that the head weighs 80 kg and there was no way to get to it.

So, we used a wire rope around the generator head body, put a steel channel strut through the loops, and used to scissor jacks to lift it basket-style all the way up.

We brought it up to the ceiling, and scooted the jacks forward (while loaded) to drop the engine in. We had to take the face plate off the fan, but it went in.

Keep in mind, this was a tight fit. It was worse than a square peg-round hole, childbirth, or trying to get that big couch into your apartment when your front door is on a tight staircase. Here's a view from the top.

How did we do that?! And there was no room to fool around with. Here's an idea of how close the gen head is to the cabin wall. Things did fit nicely in the end, though. The fans are not obstructed.

I didn't even plan on this part working.

[youtube]55-eqVZA1S0[/youtube]

Granted, we had to take out the trunk latch to get the engine in, and it has to stay cracked (for now) to keep the air flowing, but closing it up was a nice touch. Also, although it's not clear from the photos, the muffler is back in place. I'll tie the exhaust line in when I get a chance.

Now all that remains is to tweak the current controlled charging setup, mount the various items for operation (connect to auxiliary battery to start, mount laser for tachometer, fuel tank, starter switch, and throttle knob). For now, I'll send an update to our wonderful project sponsor. They'll be so proud.

GCinDC

100 MW

perhaps OT? electrics only, but fyi: Sequel to 'Who Killed The Electric Car?'?

[youtube]jkRIu5a6Sb0[/youtube]

[youtube]jkRIu5a6Sb0[/youtube]

JCG

100 W

- Joined

- Nov 10, 2008

- Messages

- 174

GCinDC said:perhaps OT? electrics only, but fyi: Sequel to 'Who Killed The Electric Car?'

A buddy of mine from New Orleans told me about that one coming out - looks interesting. I'll probably wait for it on Netflix!

Greg, your post reminded me that I forgot to post on Friday night about the stuff going on around the University with the EV1. Early last week, someone from our Operations and Maintenance Department stopped by the garage while I was finishing up wiring the current controller and other electronics in the trunk, and they said that some of the administration wanted to see the car on display for our big 2011 Earth Day celebration. This made me nervous, but I was convinced that it wouldn't be a bad idea to show off the car now that it's pretty much done. Here are some pictures from the day.

One perk was a free car wash. This guy was from Landscaping, and volunteered to help wash as long as I let him ride with me.

The Redskins fan didn't like the way the other guy was washing and nabbed the sponge from him. This caused a hilarious argument. I wish I had video.

Every show car needs a model.

We had a University SUV cover my six to hide the fact that we had no plates, and I drove it about a quarter mile through the streets and up some steep hills to get to the pavilion behind the undergraduate library near the main quad. The generator gave me the juice I needed.

Head to head with a lead-acid shuttle truck.

I put plenty of time into Q&A with students, faculty, staff, and vendors (DC recycling companies, Pepsi, etc.) that sponsored the event. But, as happens any time you wash the car, it rained all afternoon and people opted to stay dry under the main canvas.

We have to find a track to take this thing to and get some data.

GCinDC

100 MW

Awesome, J! Congrats on getting that thing out in the open!!! No vid!?

The Power of DC has a race coming up in Hagerstown, MD....

Great place to show? Get feedback/support? Though I think you have a different track in mind. If you want to sneak it onto the uni track late night, I'd be glad to help out.

The Power of DC has a race coming up in Hagerstown, MD....

Great place to show? Get feedback/support? Though I think you have a different track in mind. If you want to sneak it onto the uni track late night, I'd be glad to help out.

JCG

100 W

- Joined

- Nov 10, 2008

- Messages

- 174

An important day comes to an end. The last thing I needed was to get some open-road speed tests for the car (basically, motor phase current or DC power draw vs. steady speed) to get parameters for the overall propulsion model. This afternoon, Chris and I loaded up a trailer that he borrowed and headed out of the District and into the wilderness of Maryland.

The trailer, unfortunately, had a front railing that kept us from raising the tail ramps all the way...

... so we hacksawed that off and things fit like a glove.

Perfect parking spot when we grabbed a bite to eat on the way out of town:

We reached the undisclosed location in about an hour. This car sure does look nice on a sunny day.

We spent the next hour or so taking data on a flat stretch of road with minimal traffic. It was a little monotonous but still fun to be out in the open. On the last run back to the trailer, we switched off the charging circuit (engine still running) and Chris floored it to see what kind of speed he could get on caps-only power. Listen and you'll hear the tires squeal.

[youtube]GByhQgWWqlY[/youtube]

I now have the data that I needed. With all the work/study done up until now, I have enough to start putting together a technical paper that I'll try to get published in either IJAT or as an SAE technical paper. That's new ground for me, but I think that this work would be appreciated. If all goes well, I'll post a draft link here before any copyrights get signed over.

So, that's the end of the line for me and the EV1. I'll be headed to greener pastures over the summer (south Alabama) to start a new job there in June. If I had this whole project to do over again, I'd definitely do a few things differently. That's a good thing to be able to say, since in the end I firmly believe that I learned a great, great deal overall. I appreciate everyone following this project on ES; it was definitely easier to do this work knowing that others gave a damn. There were a lot of late, lonely nights drilling holes and wiring things up in a cold, dusty, dark, leaky, stagnant-aired, rusted-out, crumbling building that's overdue for a wrecking ball - but I do want to express my deepest thanks to Chris Harriman, Eric Cardwell, Jeff Baxter, Charlie Wermine, and Santa Claus (name withheld!) for the key parts that they played along the way. I'm proud of what we accomplished - a completely mothballed and disabled vehicle was brought back from the dead. Couldn't have done it without you guys.

Most of all, I must say thank you to the main source of financial support, General Motors. The GM engineers with whom I've discussed this project understand just what a magnificent vehicle the EV1 was - let's hope that forward-thinking engineers might hold more sway within the company in the future.

The vehicle will remain an asset of the University - as a teaching and research tool. The next researcher and research team will undoubtedly learn as much as I did when they next open the hood (or trunk!) and get to work. Until then...

"She rests in silence, dreaming of the day she'll run free"

(Sorry for the cheese. But I think I'm entitled.)

The trailer, unfortunately, had a front railing that kept us from raising the tail ramps all the way...

... so we hacksawed that off and things fit like a glove.

Perfect parking spot when we grabbed a bite to eat on the way out of town:

We reached the undisclosed location in about an hour. This car sure does look nice on a sunny day.

We spent the next hour or so taking data on a flat stretch of road with minimal traffic. It was a little monotonous but still fun to be out in the open. On the last run back to the trailer, we switched off the charging circuit (engine still running) and Chris floored it to see what kind of speed he could get on caps-only power. Listen and you'll hear the tires squeal.

[youtube]GByhQgWWqlY[/youtube]

I now have the data that I needed. With all the work/study done up until now, I have enough to start putting together a technical paper that I'll try to get published in either IJAT or as an SAE technical paper. That's new ground for me, but I think that this work would be appreciated. If all goes well, I'll post a draft link here before any copyrights get signed over.

So, that's the end of the line for me and the EV1. I'll be headed to greener pastures over the summer (south Alabama) to start a new job there in June. If I had this whole project to do over again, I'd definitely do a few things differently. That's a good thing to be able to say, since in the end I firmly believe that I learned a great, great deal overall. I appreciate everyone following this project on ES; it was definitely easier to do this work knowing that others gave a damn. There were a lot of late, lonely nights drilling holes and wiring things up in a cold, dusty, dark, leaky, stagnant-aired, rusted-out, crumbling building that's overdue for a wrecking ball - but I do want to express my deepest thanks to Chris Harriman, Eric Cardwell, Jeff Baxter, Charlie Wermine, and Santa Claus (name withheld!) for the key parts that they played along the way. I'm proud of what we accomplished - a completely mothballed and disabled vehicle was brought back from the dead. Couldn't have done it without you guys.

Most of all, I must say thank you to the main source of financial support, General Motors. The GM engineers with whom I've discussed this project understand just what a magnificent vehicle the EV1 was - let's hope that forward-thinking engineers might hold more sway within the company in the future.

The vehicle will remain an asset of the University - as a teaching and research tool. The next researcher and research team will undoubtedly learn as much as I did when they next open the hood (or trunk!) and get to work. Until then...

"She rests in silence, dreaming of the day she'll run free"

(Sorry for the cheese. But I think I'm entitled.)

GCinDC

100 MW

Wow. Wasn't ready for that ending! You put so much work into it! Oh well, good luck in AL!

Are you gonna print out this thread and leave it in the glove compartment as a manual?

What was the top speed in the vid?

Are you gonna print out this thread and leave it in the glove compartment as a manual?

What was the top speed in the vid?

paultrafalgar

10 kW

Very well done, Jason! I too am shocked by the end of the project. I hope you will encourage whoever takes it over to continue posting news here. All the best in your new job. Best wishes.

JCG

100 W

- Joined

- Nov 10, 2008

- Messages

- 174

Thanks Paul - I guess I got everything accomplished that I set out to do, minus the ammonia carburetor conversion, but I'm actually a bit glad that we didn't go down that road just yet - things became too rushed here as the year began. Also, it leaves the door open for a better engine-generator set to test out in the open in the coming year or two. Carbureted is not really the best way to go, so it's time to start learning about fuel injection, spark advance, air/fuel ratios... in a high compression SI engine. Stationary application first, but I also would really like to start a vehicle from scratch, maybe that will be possible as a separate research project for next year. One of the problems with the EV1 was how little space there was inside, using whatever was left over from the pure EV design, which was not much at all!

Greg, as George Bush would say, "Mission Accomplished." I'm not 100% sure if there even is a glove box... but I will be in close contact with the guy from Mechanical Engineering who will likely be the new custodian of the work area, so I'll give him all the info I can. And the wet/dry vacuum.

As for the top speed, I am in the process of figuring it out. The only thing that's clear is that the conversion that I used to correlate the displayed "motor RPM" (0-10 V signal) to motor frequency, to wheel RPM, to vehicle speed is way off. When we started tests yesterday with a progression of 20, 25, 30, 35, etc. mph cruising it was clear that we were going much faster than those speeds at the voltage displays I'd calculated. I'm going to check with the controller's programmer soon to see what factor I missed or misread. Anyway, it seemed that we got up to at least 75 mph a few times, although my conversion factor suggested only 45 mph from the display. The good news is that all the data is still valid, I just need to translate it by a constant multiple. Worst case, I can raise the front wheels and use my laser tachometer on the tires while checking the display.

Greg, as George Bush would say, "Mission Accomplished." I'm not 100% sure if there even is a glove box... but I will be in close contact with the guy from Mechanical Engineering who will likely be the new custodian of the work area, so I'll give him all the info I can. And the wet/dry vacuum.

As for the top speed, I am in the process of figuring it out. The only thing that's clear is that the conversion that I used to correlate the displayed "motor RPM" (0-10 V signal) to motor frequency, to wheel RPM, to vehicle speed is way off. When we started tests yesterday with a progression of 20, 25, 30, 35, etc. mph cruising it was clear that we were going much faster than those speeds at the voltage displays I'd calculated. I'm going to check with the controller's programmer soon to see what factor I missed or misread. Anyway, it seemed that we got up to at least 75 mph a few times, although my conversion factor suggested only 45 mph from the display. The good news is that all the data is still valid, I just need to translate it by a constant multiple. Worst case, I can raise the front wheels and use my laser tachometer on the tires while checking the display.

TylerDurden

100 GW

Stellar work. Thanks for sharing it here on ES.

Look forward to your next!

Look forward to your next!

Sorry to see the project come to an end. I hope the next custodian of the EV1 will share with us too.

JCG

100 W

- Joined

- Nov 10, 2008

- Messages

- 174

TD & fechter (as I finally spell your handle correctly) - much appreciated. I'll definitely recommend posting of future work - the people at ES are on the whole extremely gracious, generous, and helpful! I'm glad that no matter where I go that I'll still have an account here (until I get banned!  ).

).

Best

Jason

Best

Jason

GCinDC

100 MW

taking the trike with you?

JCG

100 W

- Joined

- Nov 10, 2008

- Messages

- 174

Paper draft is written and under peer review.

Link to PDF

If anyone has specific comments or questions, shoot me a PM. I've already spotted several grammatical errors, the kind that only become visible after you hit the "submit" button.

I can keep this up until I sign away the copyrights. Please don't distribute over e-mail - download from the link. Thanks!

Link to PDF

If anyone has specific comments or questions, shoot me a PM. I've already spotted several grammatical errors, the kind that only become visible after you hit the "submit" button.

I can keep this up until I sign away the copyrights. Please don't distribute over e-mail - download from the link. Thanks!

paultrafalgar

10 kW

I read your elegantly written thesis. I found no typos or grammatical errors - I didn't check the maths - not my strong point. But one thing bothers me (not wishing to rain on your parade):

From page 26 we have:

"These fuel economy values are equivalent to 42.3 city and 72.2 highway miles per US gallon."

The Volkswagen XL1 concept car (http://www.volkswagen.co.uk/volkswagen-world/news/282/volkswagen-unveils-the-xl1-super-efficient-vehicle-in-qatar) is quoted as having a fuel consumption of 313 mpg (I don't know if that's US or Imperial gallons), but it seems a lot more than your figures which are similar to current Prius levels.

I am surprised at this. Would you conclude that Serial Hybrid is not the way to go (the VW appears to be a parallel-hybrid) or that several million dollars and a big research team can optimize the design where a one-man band can't be expected to compete.

Would your EV1 conversion benefit from the incorporation of in-wheel motors (e.g. Michelin Active Wheel) do you think?

Best wises,

Paul

From page 26 we have:

"These fuel economy values are equivalent to 42.3 city and 72.2 highway miles per US gallon."

The Volkswagen XL1 concept car (http://www.volkswagen.co.uk/volkswagen-world/news/282/volkswagen-unveils-the-xl1-super-efficient-vehicle-in-qatar) is quoted as having a fuel consumption of 313 mpg (I don't know if that's US or Imperial gallons), but it seems a lot more than your figures which are similar to current Prius levels.

I am surprised at this. Would you conclude that Serial Hybrid is not the way to go (the VW appears to be a parallel-hybrid) or that several million dollars and a big research team can optimize the design where a one-man band can't be expected to compete.

Would your EV1 conversion benefit from the incorporation of in-wheel motors (e.g. Michelin Active Wheel) do you think?

Best wises,

Paul

Similar threads

- Replies

- 1

- Views

- 244

- Replies

- 5

- Views

- 700

- Replies

- 4

- Views

- 427