LeftieBiker said:

DrkAngel said:

Any bike shop will do it.

Shouldn't cost much.

Print a picture or show them my referenced thread to explain washer mod.

I think I've found a shop that will repair it, at least... In the spoke thread, someone mentions that Currie adopted a similar lacing pattern; does that mean my 2013 doesn't need to have the pattern changed? So 13G SS spokes, 18 each of 258mm and 260mm, is what I need, plus maybe the washers? I'd like to use the washers, but the bike shop, even if they went for the idea, would charge a lot more. And if I take them off and do the washer prep myself, they won't see the lacing pattern...

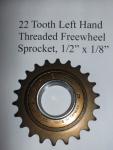

Look at the picture!

This is my solution ... as the proper spoke directionality.

Hub, turning counter-clockwise, uses the spokes with the "elbow" turned outward to pull the rim.

If Currie had adopted this method then you probably would not have gotten any broken spokes.

Picture of Currie lacing with pulling elbows turned inward, without washers, which clearly demonstrates the damaging stress.

These spokes break at the elbows - near arrow locations.

The elbows tuned inward gives the spokes a more damaging stress angle.

The narrowness of the spoke flange amplifies elbow stress.

Adding the washer pulls the elbow closer to the flange, which greatly reduces the leverage factor - .

Adding the washer = pulling the elbow close to the flange, will reduce the leverage stress to possibly 1/4 which might relate to a 16x lifespan.

12g spokes and washer mod, overkill ... but demonstrates my solution.

Washer mod is simply sliding a #4 washer on each spoke before installing.

Local BS should have 14g spokes available and should work nicely.

SS preferred.

13g are better, if available, or don't mind waiting to get them.

While I confess that I might use a bit of technical "shorthand", I try to give reasonably complete and understandable explanations-instructions in my original posts.

If not understandable, perhaps you should not attempt my mods by yourself?

Have a buddy look at this thread and "translate" it for you?

Better yet refer the bike shop guy to the thread, it is his field of expertise and probably instantly clear.