I have been lurking here long enough and I'd like your feedback on my draft part list for my first build!

The donor bike is a 1980 Honda CB125 S. I would like to be able to get up to 65mph (105kph) if needed, but will mostly be riding in town at ~30mph (48 kph). I don't need more than 20 miles of range. But I am thinking of building a removable second battery to extend my range on longer trips.

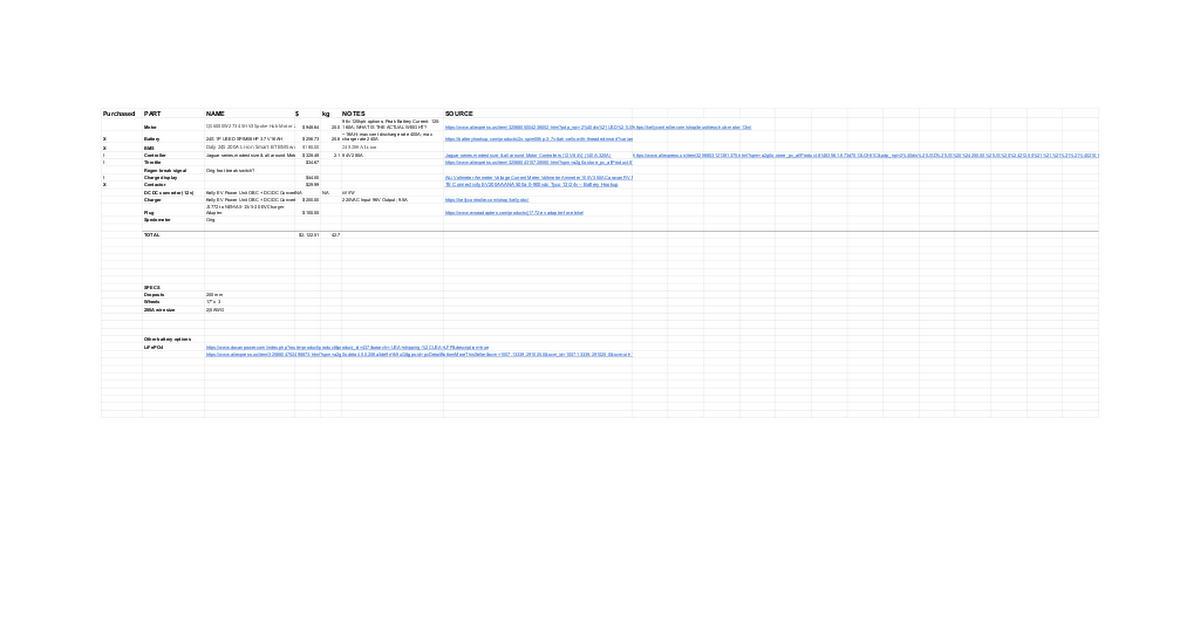

Here is a link to the parts list (photo below):

docs.google.com

docs.google.com

The donor bike is a 1980 Honda CB125 S. I would like to be able to get up to 65mph (105kph) if needed, but will mostly be riding in town at ~30mph (48 kph). I don't need more than 20 miles of range. But I am thinking of building a removable second battery to extend my range on longer trips.

Here is a link to the parts list (photo below):

EV CB125 parts

Sheet1 Purchased,PART,NAME,$,kg,NOTES,SOURCE Motor,QS 6000W 273 45H V3 Spoke Hub Motor 200mm Dropout,$948.64,20.0,96v 120kph options; Peak Battery Current: 120-160A; WHAT IS THE ACTUAL WEIGHT?,<a href="https://www.aliexpress.us/item/3256805004238052.html?pdp_npi=2%40dis%21USD%21US%20%24599.45%21...