sl33py

10 kW

cdn said:jamesonotc said:cdn said:Great write up. Now can proceed to do the same. Only thing missing is to print the enclosure. Where did you get it printed? Hopefully some place local because I'm in Renton.

Good to see you another local,I too am in Renton

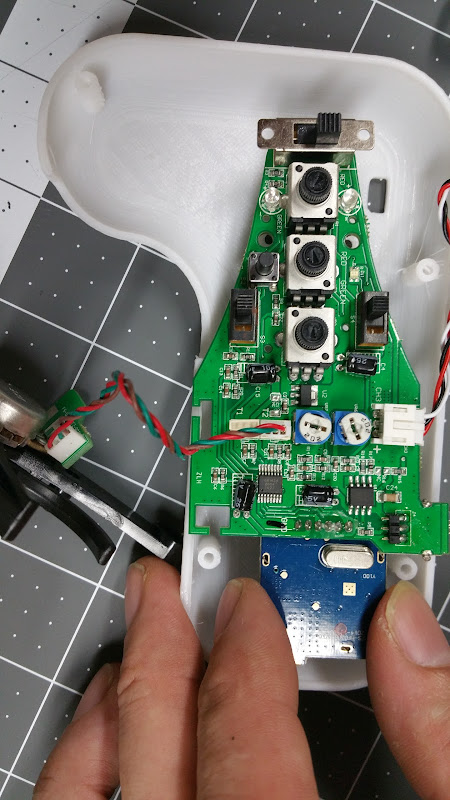

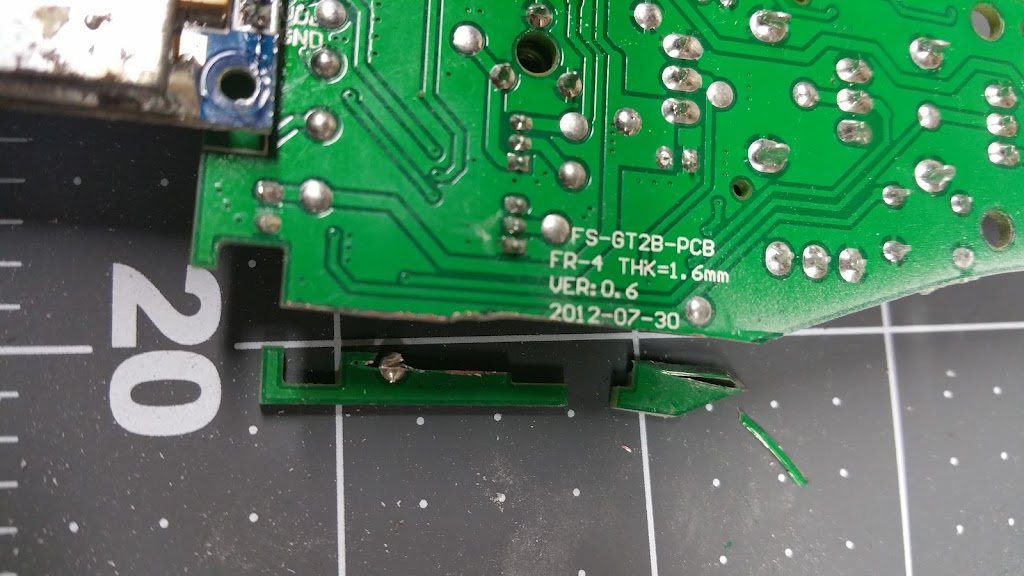

I'm currently building a board and will be using a case I got from sl33py for my gt2b swap, lets link up sometime!

how far are you along with your project on the other portion of your build?

Sounds like a plan. I'm pretty close to final assembly. This build is a revamp of an existing running board. Just waiting for bearings.

cdn - i have some spare bearings coming out my ears... All yours if you want to meetup since you are local? Shoot me a PM.