darseygodwin

1 W

- Joined

- Jul 31, 2016

- Messages

- 50

@66sametk@gmail.com

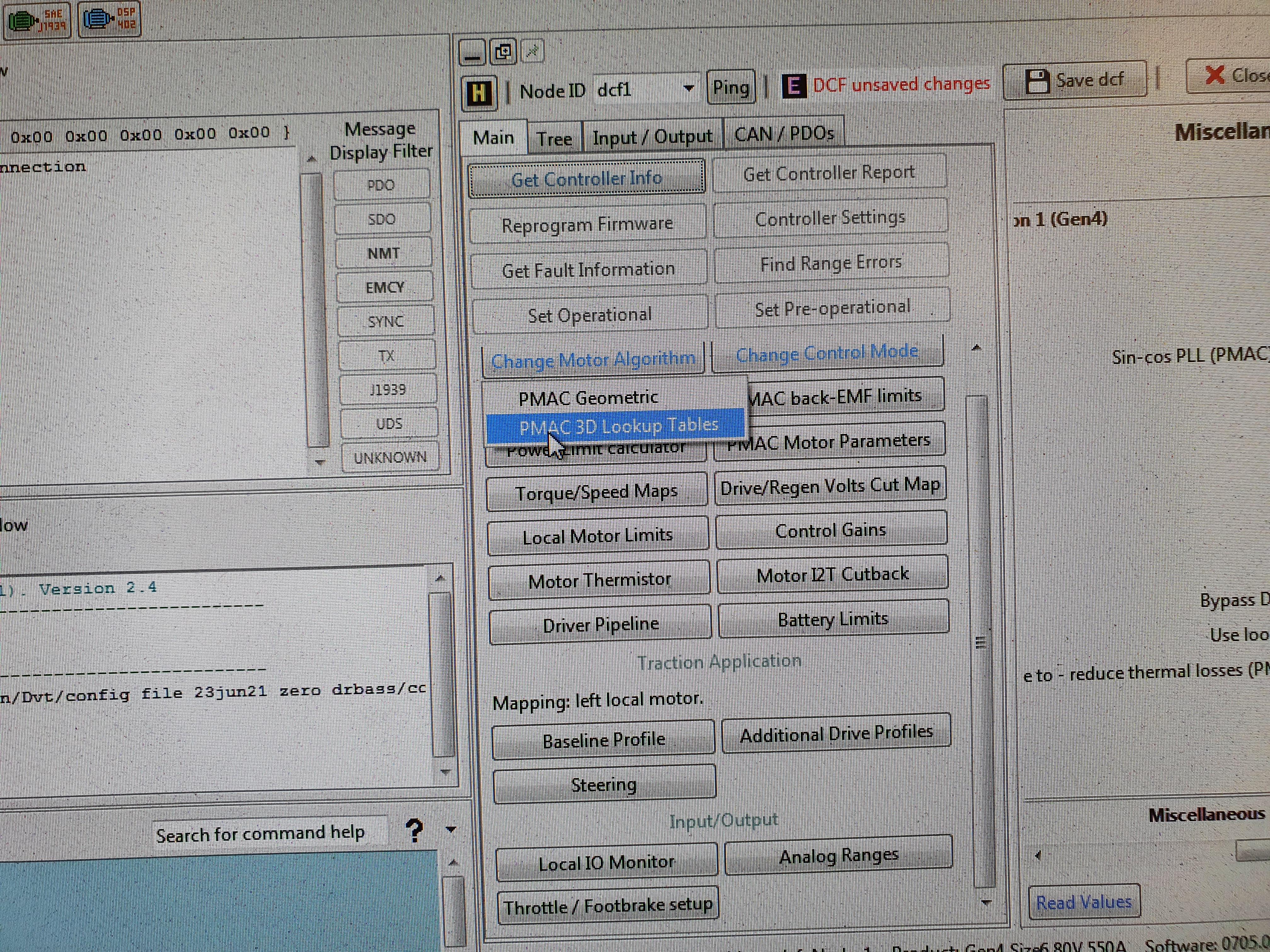

From a high level, You would use the Sevcon DVT software with an IXXAT usb-serial converter that was used to program the controller in the first place, and add your exported variables to the TPDO channels in the TPDO tab. The controller needs to be in pre-op to save changes.

Finally, verify the variables are now shown in the "vehicle monitor" window. This will also help you determine the scaling needed in your receiving node.

These steps are explained better in a Sevcon app note about programming rpdo/tpdos, but I don't have a link available right now. It's Google searchable though. Good luck!

Sent from my SM-N770F using Tapatalk

From a high level, You would use the Sevcon DVT software with an IXXAT usb-serial converter that was used to program the controller in the first place, and add your exported variables to the TPDO channels in the TPDO tab. The controller needs to be in pre-op to save changes.

Finally, verify the variables are now shown in the "vehicle monitor" window. This will also help you determine the scaling needed in your receiving node.

These steps are explained better in a Sevcon app note about programming rpdo/tpdos, but I don't have a link available right now. It's Google searchable though. Good luck!

Sent from my SM-N770F using Tapatalk