illegalbike

10 W

- Joined

- Jan 28, 2021

- Messages

- 94

fechter said:I like how you made the video in front of a gas station :wink:

I'm glad that you appreciated our humor

fechter said:I like how you made the video in front of a gas station :wink:

illegalbike said:yellow illegalbike ............................. OK!

999zip999 said:Damn Russians I'm going to get a submarine I'm going to come over and I'm going to steall that bike. and declared it was an American made USA .

of course if I want to get a submarine I'm going to have to ask Columbia that they would help me.

good job

mxlemming said:illegalbike said:mxlemming said:Mr illegal, could you share some details of how you've constructed the main pivot? Looks very tidy, but the bearing axial loading etc?

in the last video I demonstrated the main pivot, maybe it will be useful for you. The motor, frame and swingarm on the same axis are difficult for mass production, the next frames I will design with inrunner motor

Unfortunately my Russian isn't great. I watched the whole video to find the bit I think was your explanation but... Didn't really get it. There's no English translation or subtitles on YouTube unfortunately.

Would be cool to see this mass produced. Your plan to sell them? How much?

rider63 said:Hi, awesome project, seem to be a really good machine.

you made it on aluminium, what nuance? did you made thermal post treatment after welding?

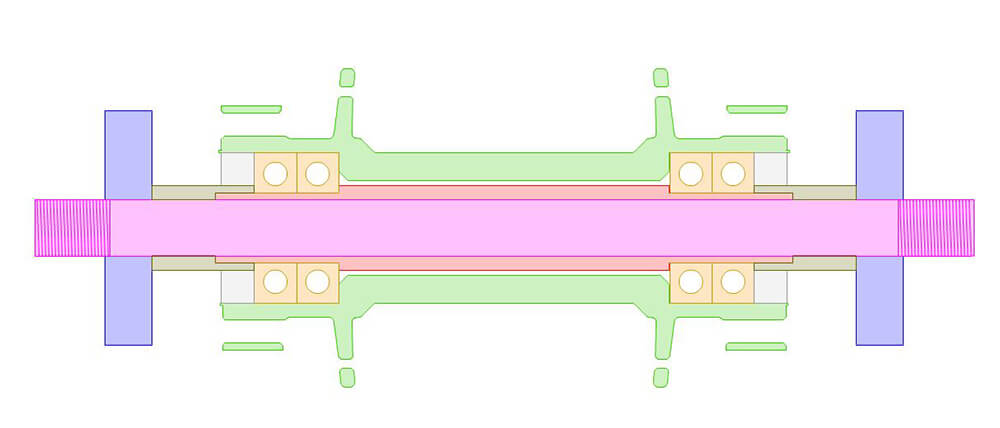

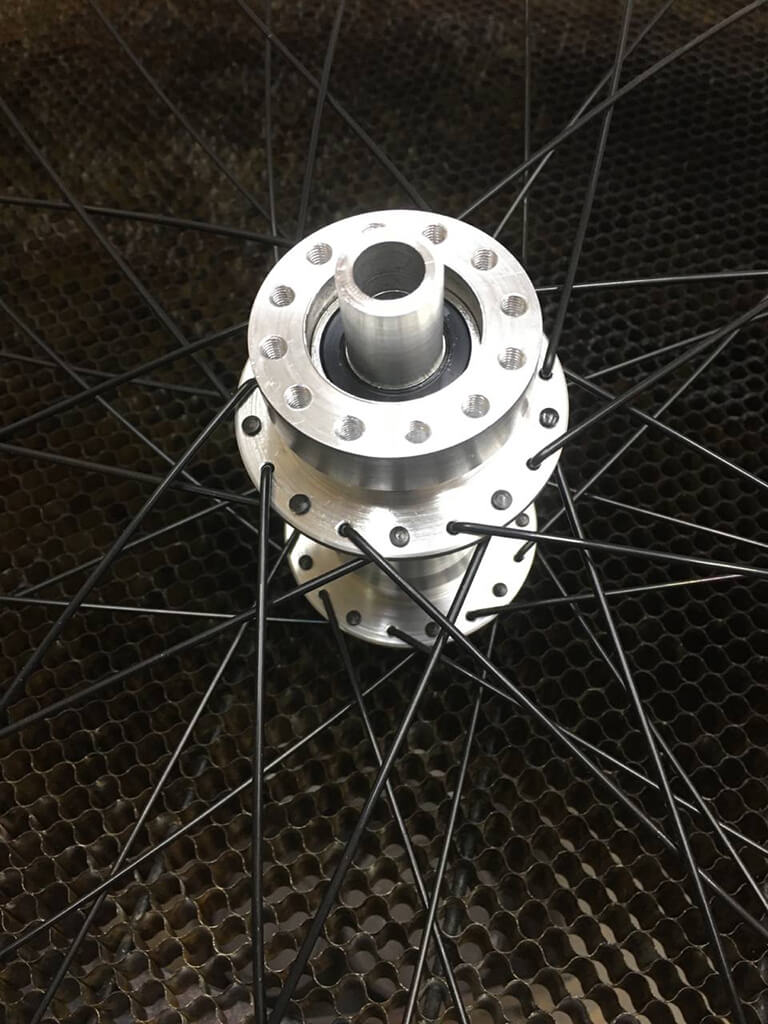

ZeroEm said:I'm interested in how the motor is mounted and lock into the swing arm? I see some pictures and have ideas in my head but would like a better look.

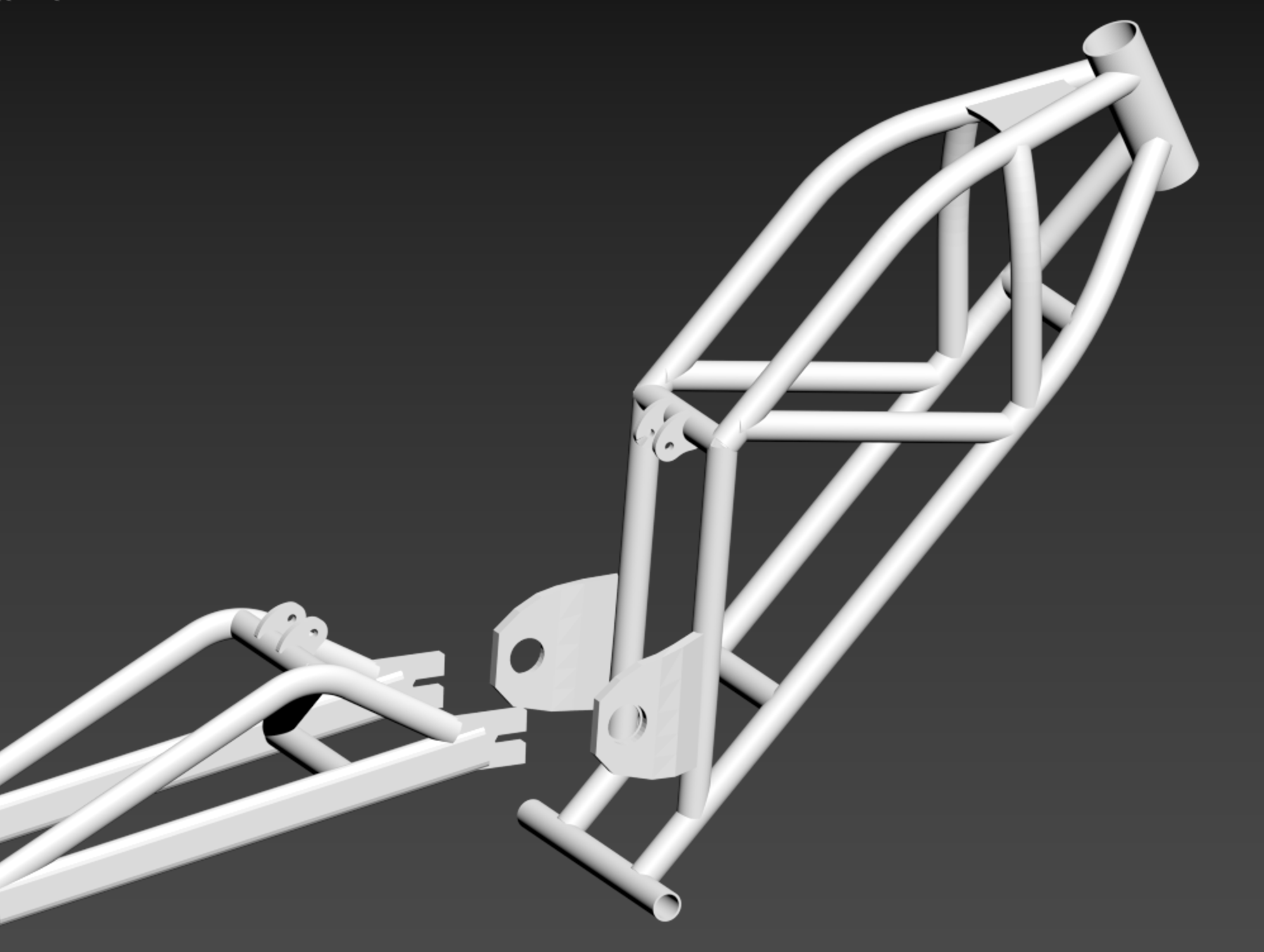

dev2 said:Hey Dmitry, another question - what's all the software you are using for design? Thanks.

by illegalbike » Oct 10 2021 5:07pm

unfortunately, all frames of this version are sold and I cannot show this unit disassembled, there are several preserved photos from different anglesZeroEm wrote: ↑Sep 27 2021 9:45am

I'm interested in how the motor is mounted and lock into the swing arm? I see some pictures and have ideas in my head but would like a better look.

illegalbike said:rider63 said:Hi, awesome project, seem to be a really good machine.

you made it on aluminium, what nuance? did you made thermal post treatment after welding?

hi, i didn't learn heat treatment, but i'm cunning, so i used an aluminum alloy with 5% magnesium. This alloy does not require heat treatment and is easy to weld. Alloy AMg5 or another name 5056

Hummina Shadeeba said:are the frames for sale in the near future?

TorontoBuilder said:I love your builds, but even more I love the videos of you riding at high speed with very little noise.

Hummina Shadeeba said:i cant speak russian but at minute six as you point to the axle it sounds problematic. https://www.youtube.com/watch?v=sEaH_lAp8Jk

im guessing it's problematic attaching the hub motor's axle, which is both threaded and with flats, to the front of the frame. Im guessing you banged a metal tube on the motor shaft ends to make round shafts for bearings?

Hummina Shadeeba said:Using a hub motor as mid drive seems ideal. Why are you are interested in using an inrunner next?

How much and how soonillegalbike said:Hummina Shadeeba said:are the frames for sale in the near future?

Yes

by Hummina Shadeeba » Oct 25 2021 9:46am

illegalbike wrote: ↑Oct 24 2021 1:46pm

Hummina Shadeeba wrote: ↑Oct 21 2021 10:04pm

are the frames for sale in the near future?

Yes

How much and how soon

everywhere selling the motor says its max rpm is 600. I don’t know ur gearing but think u said 2:1 and looks fast. I wonder what rpm you do and why they state 600rpm and if in a built wheel the spoke tension would be added to the force but when running the motor bare as you do.. what you think?