jur said:

casainho said:

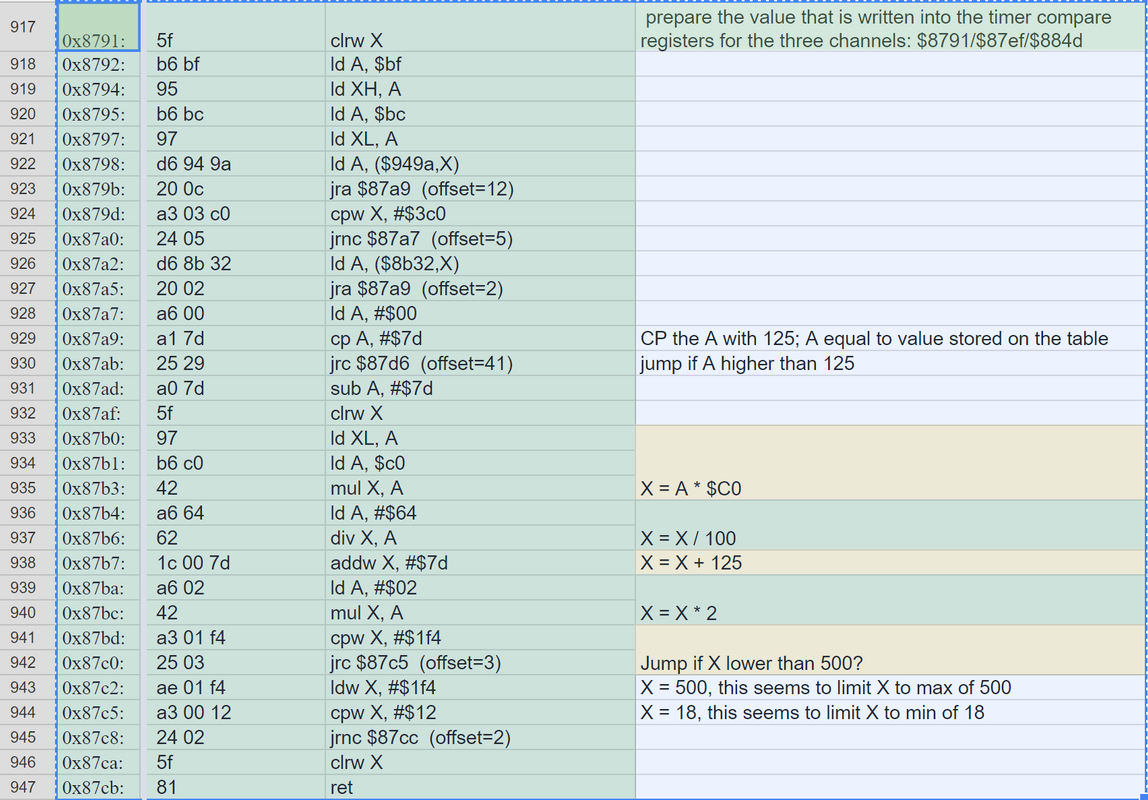

Thanks for the info. For now, I think that even with float operations, for the measured times on my experiences, it should work. Optimizations can come later.

Could you please state exactly what you need for solving the math:

Inputs, equations to solve and required outputs. I am deep into generating the simplest possible math operations but it would be most efficient if you could please spec what you need.

Looking at the documentation from Shane Colton here:

- https://opensourceebikefirmware.bitbucket.io/development/Motor_control--FOC--Shane_Colton_documentation_and_firmware.html

- https://github.com/EGG-electric-unicycle/documentation/blob/master/Shane_Colton/3phduo.pdf

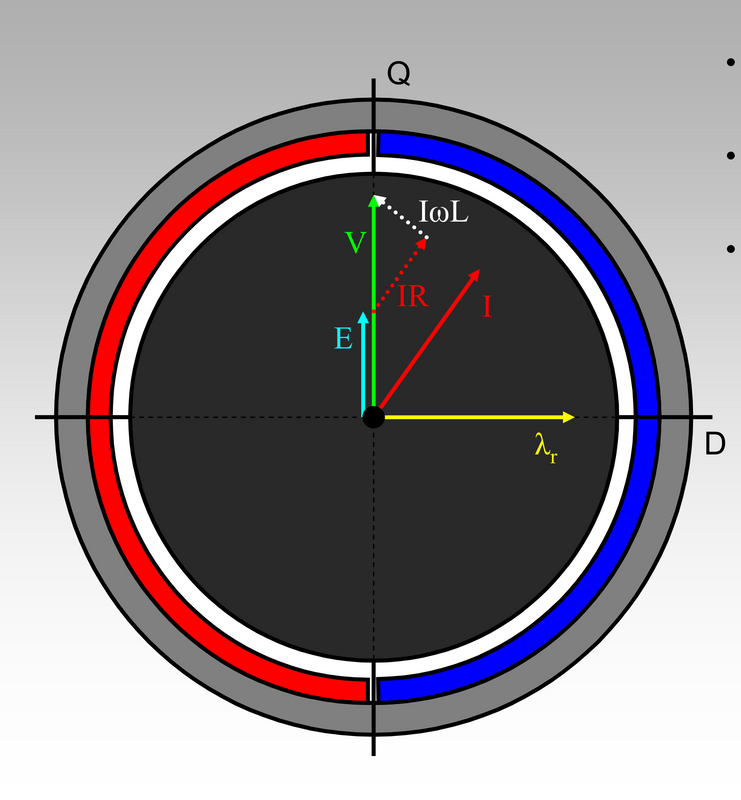

1. Without align current with BEMF (inefficient controlling of the motor)

2. Aligning current with BEMF (efficient controlling of the motor)

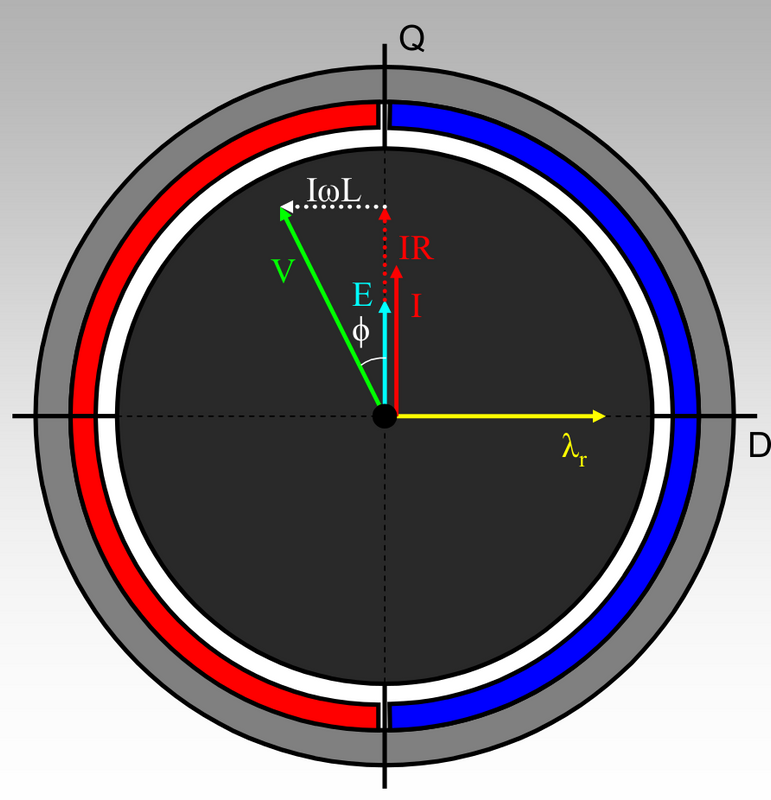

I know that we want to be at 2.

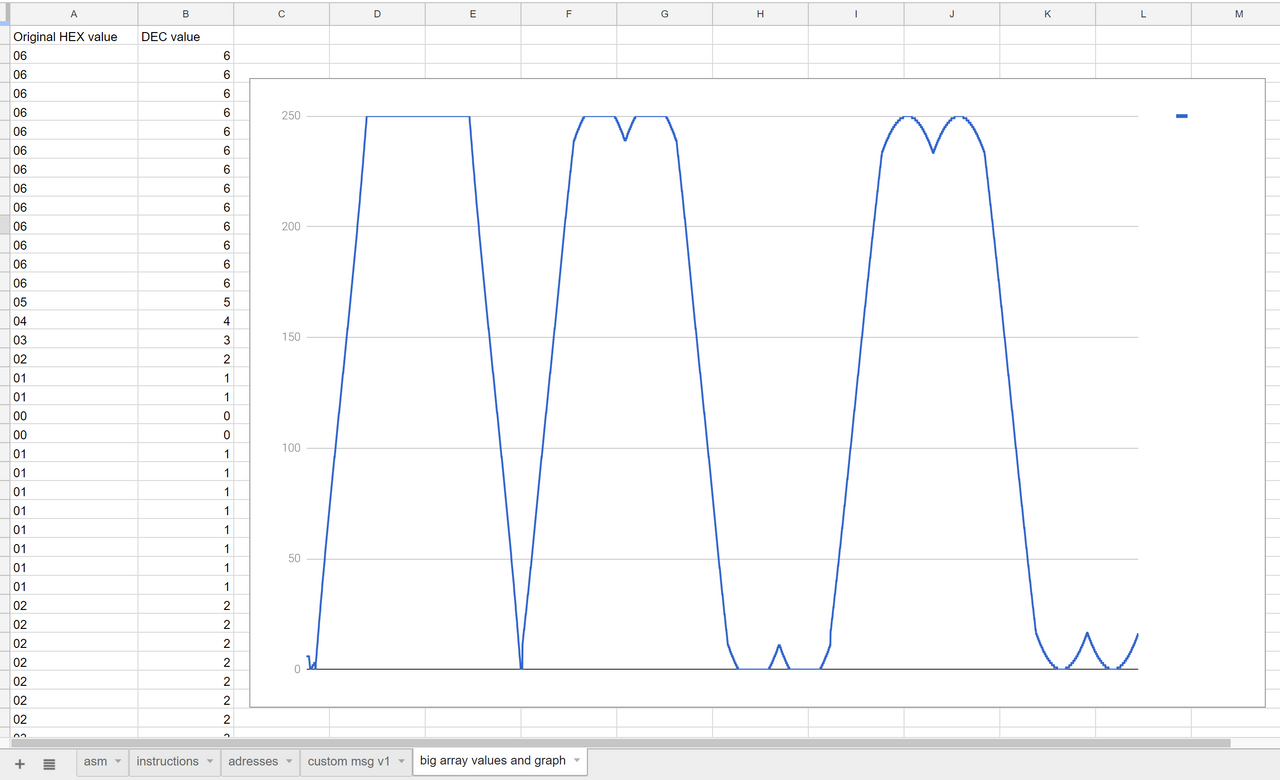

I think as inputs we have:

- direction of Q axis, as we can measure BEMF by rotating the motor with our hands and BEMF direction is max value of the sinewave measured and then we can reference to hall sensors transition signals

- we don't know phi r (yellow vector) and I think we don't need it. It just represents north pole of one magnet of rotor

- I we can measure. I is the phase current however we just can measure battery current on the shunt and I phase current = I battery current * actual PWM duty_cycle.

- IR is I * motor coil resistance, that is why we need to measure the resistance

- E is the BEMF, which is motor constant of generated volts per RPM, and it can be measured but we know for our motors can be something near as 36V(48V) / 4000 RPM. Knowing the motor speed, that we can measure using hall sensors signals, we can calculate the E

-- phi r (yellow vector) is equal to BEMF

- IwL can be calculated knowing the I, motor speed and L motor inductance, that is why we need to measure the coils motor inductance

- V is the phase voltage we apply to the motor phases, and it is Vbattery that we can measure * currently PWM duty_cycle that we apply

As we can see angle teta increases with IwL and IR, so, depends from motor speed and current. We can measure both and we know that angle between IR and IwL are always 90 degrees. How can we calculate the angle on 1. so we can advance the phase voltage V by that angle value and I will be in aligned with E an so we will get the higher torque per amp??

On the second link for documentation of Shane Colton, he talks about some math to calculate the angle:

Please look at this message of Stancecoke: https://endless-sphere.com/forums/viewtopic.php?f=30&t=93818&start=50#p1375474

And please note that we don't need the angle value, we may just need to know if the angle is positive, negative or near zero. On Kunteng controller, in our firmware, we just do that and it works very well!! See here a resume: https://opensourceebikefirmware.bitbucket.io/development/Datasheets_and_application_notes--Endless-sphere.com_forum_messages--2017.10.23_-_FOC_and_no_FOC_comparison.html

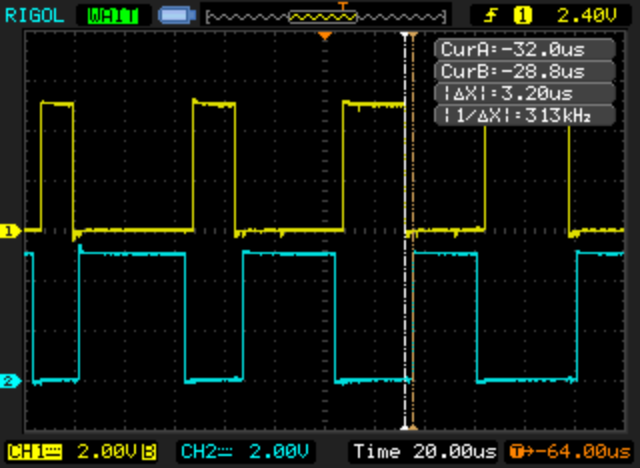

This is all the I know for now. And the PWM signal on TSDZ2 motor controller is just the same as on Kunteng, that we already implemented and works very well. On TSDZ2, there is no phase current sensor and I think it is not needed because it just need to work with a specific motor with a know R and L values unlike on Kunteng that should work with most hub and even mid driver motors -- for instance, the PWM frequency on Kunteng is just the same 16kHz.