markcycle

10 kW

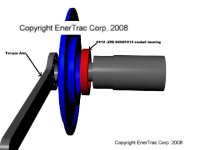

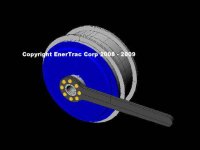

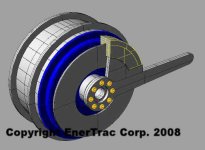

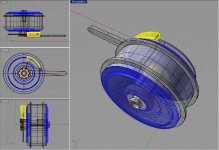

I hope to have a 10KW, 20kw peak hub motor to offer for sale in the next few weeks and over the next 3 months I will be offering motorcycle hub motor kits with discs brakes. This is a custom hub motor build to my spec's by a major manufacturer.

Testing will begin shortly using my motorcycle. After that I am going to convert a Ninja 250 using this hub motor.

I would be interested in a list of motorcycles most likely would be upgraded to electric using a hub motor. With everyone's help (Dimensions pictures and suggestions) Those would be the bikes I would develop hub motor conversion kits for.

Imagine using a hub motor, an ICE motorcycle can be a hybrid, plug in hybrid or a fully electric bike. Details shortly

All hub motor will be laced to a DOT approved motorcycle rim as is in my motorcycle build and have Regen braking. This is not a offer to sell at this point, that will happen in a few weeks (3 to 5 weeks). When I have product to sell I will move to the selling section on the forum.

My goal here is to present the concept of a true motorcycle class hub motor spoked to a DOT approved motorcycle rim. Also introduce the concept of keeping the ICE engine and converting bikes to plugin hybrids. In concept it's relativity simple. Dealing with the details can make it complicated, depending on the bike.

Stay tuned

Mark

Testing will begin shortly using my motorcycle. After that I am going to convert a Ninja 250 using this hub motor.

I would be interested in a list of motorcycles most likely would be upgraded to electric using a hub motor. With everyone's help (Dimensions pictures and suggestions) Those would be the bikes I would develop hub motor conversion kits for.

Imagine using a hub motor, an ICE motorcycle can be a hybrid, plug in hybrid or a fully electric bike. Details shortly

All hub motor will be laced to a DOT approved motorcycle rim as is in my motorcycle build and have Regen braking. This is not a offer to sell at this point, that will happen in a few weeks (3 to 5 weeks). When I have product to sell I will move to the selling section on the forum.

My goal here is to present the concept of a true motorcycle class hub motor spoked to a DOT approved motorcycle rim. Also introduce the concept of keeping the ICE engine and converting bikes to plugin hybrids. In concept it's relativity simple. Dealing with the details can make it complicated, depending on the bike.

Stay tuned

Mark