Ken Taylor

100 W

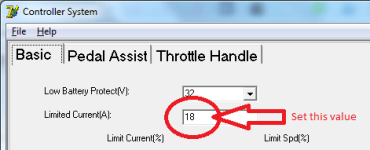

This is a question for the programming thread but the answer is:-Melbourne said:What is the easier/quick way to limit the power to 20Amp as my Lifepo4 battery will not like 25a?

I've tested that this setting works.

As an aside and because I see you also have a 350W BBS01. You can make a 350W BBS01 the same as a 250W BBS01 by changing the Limited Current (A) from 18 to 15 or vice versa. The only other difference is the numbers engraved on the bottom of the motor.