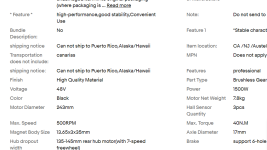

I see a lot of hub motors, some geared and some direct drive on ebay for less than $100 up to about $160.

However I never see the spokes and rim under what other people ordered with the motor.

There should be spokes and rims from 20" up to 28" to build the wheels but I do not see any.

The front e bikeling motor on my Giant is making noise. I do not think it can be rebuilt like Bafang. Lots of repair parts for Bafang : Not ebikeling. I also have a 350 watt 36V Bafang that has a sensor issue. One or more is burned out. I had another Bafang that had a really bent rim so my friend swapped motors and sold the ebike.

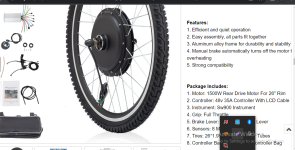

I am looking to have him build me a wheel for the motor with the bad sensor and order a sensor less controller to run it. I could order the sensor array but a sensor less controller is only a few bucks more.

I was hoping to build a couple of ebikes with dual 350 to 500 watt motors and fully functional pedal gears and brakes. I could also include the battery in a rear rack. I could make a modest profit. I just need links to the spokes and rims or a place who can send me the wheel parts if I email the link to the motor ?????

My friend is good with brakes and I am learning. He can do disk if I build a 1,500 watt e bike. Since 26" is most common with kits building a wheel to fit a bike frame makes sense and hooking up brakes easier as everything lines up. 700c , 27.5" and 28" are getting more popular especially for taller folk.

Also dual 350 or 500 watt geared hub motors have a slight advantage over 1,000 watt direct drive in traction but around 5 mph slower than a single 1,000 watt direct drive. Geared hub motors offer superior torque so an advantage up hills. Also the direct drive is about 5 to 7 pounds heavier than two geared hub motors.

I know this as I have been running dual 26" 350 watt Bafangs for at least a couple years now and I weigh around 230 and excellent up small hills and very reliable. ebikeling geared 500 watt hub motors are not as good as 350 watt Bafang.

I hope someone will let me know. I would like to get started.

Skyler

However I never see the spokes and rim under what other people ordered with the motor.

There should be spokes and rims from 20" up to 28" to build the wheels but I do not see any.

The front e bikeling motor on my Giant is making noise. I do not think it can be rebuilt like Bafang. Lots of repair parts for Bafang : Not ebikeling. I also have a 350 watt 36V Bafang that has a sensor issue. One or more is burned out. I had another Bafang that had a really bent rim so my friend swapped motors and sold the ebike.

I am looking to have him build me a wheel for the motor with the bad sensor and order a sensor less controller to run it. I could order the sensor array but a sensor less controller is only a few bucks more.

I was hoping to build a couple of ebikes with dual 350 to 500 watt motors and fully functional pedal gears and brakes. I could also include the battery in a rear rack. I could make a modest profit. I just need links to the spokes and rims or a place who can send me the wheel parts if I email the link to the motor ?????

My friend is good with brakes and I am learning. He can do disk if I build a 1,500 watt e bike. Since 26" is most common with kits building a wheel to fit a bike frame makes sense and hooking up brakes easier as everything lines up. 700c , 27.5" and 28" are getting more popular especially for taller folk.

Also dual 350 or 500 watt geared hub motors have a slight advantage over 1,000 watt direct drive in traction but around 5 mph slower than a single 1,000 watt direct drive. Geared hub motors offer superior torque so an advantage up hills. Also the direct drive is about 5 to 7 pounds heavier than two geared hub motors.

I know this as I have been running dual 26" 350 watt Bafangs for at least a couple years now and I weigh around 230 and excellent up small hills and very reliable. ebikeling geared 500 watt hub motors are not as good as 350 watt Bafang.

I hope someone will let me know. I would like to get started.

Skyler

Attachments

Last edited: