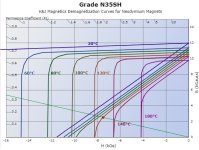

Max allow temp also depends on your controller

Power advance (flux weakening)

It must be tested with the stator in place

Baseline test is unpowered with motor naturally aligned (lowest resistance flux return path). Put motor in oven until entire motor at same temp. Remove motor from oven and allow to return to room temp (overnight or use water bath to speed process) remeasure mags with hole in side cover to make it easy. Bump oven temp 5c and retest. Repeat until mags do not recover at room temp. This is the best case max temp.

More testing is needed for real world max temp but it gives you a good baseline if you just want to guess and give urself leeway based on how aggressive the motor is being used (and also account for skimpy dysprosium mag batches)

Power advance (flux weakening)

It must be tested with the stator in place

Baseline test is unpowered with motor naturally aligned (lowest resistance flux return path). Put motor in oven until entire motor at same temp. Remove motor from oven and allow to return to room temp (overnight or use water bath to speed process) remeasure mags with hole in side cover to make it easy. Bump oven temp 5c and retest. Repeat until mags do not recover at room temp. This is the best case max temp.

More testing is needed for real world max temp but it gives you a good baseline if you just want to guess and give urself leeway based on how aggressive the motor is being used (and also account for skimpy dysprosium mag batches)