Hi,

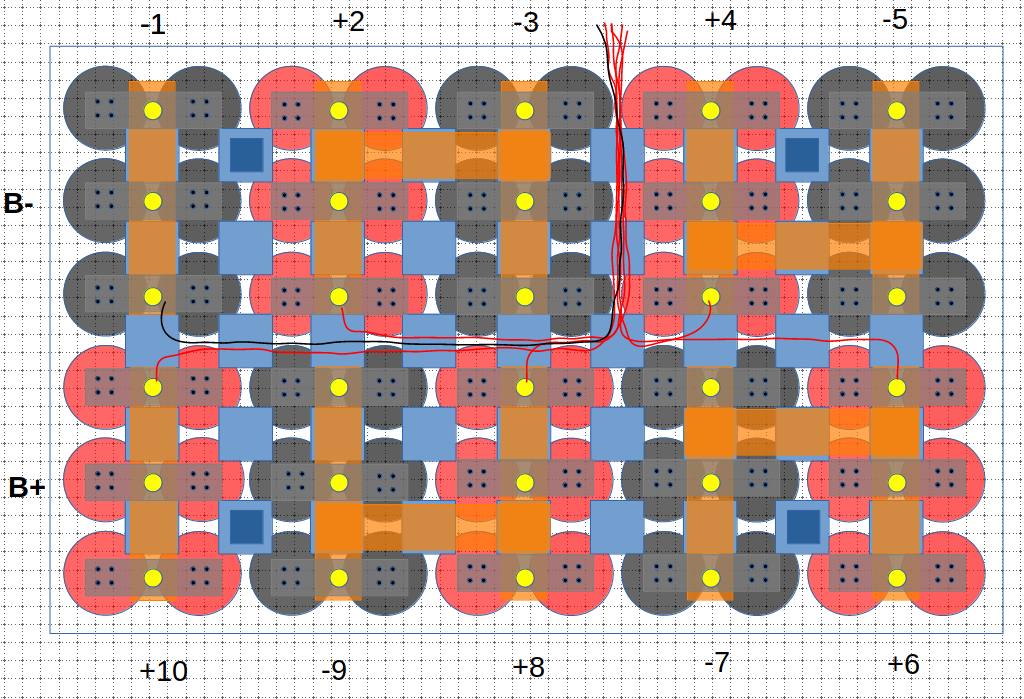

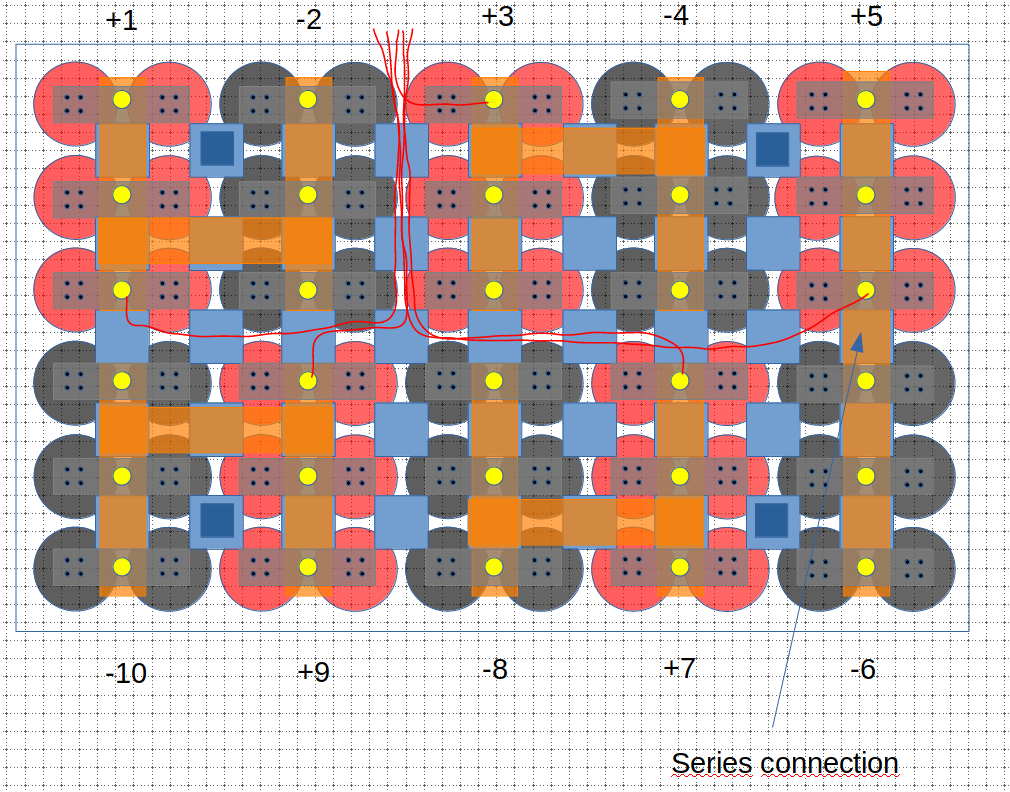

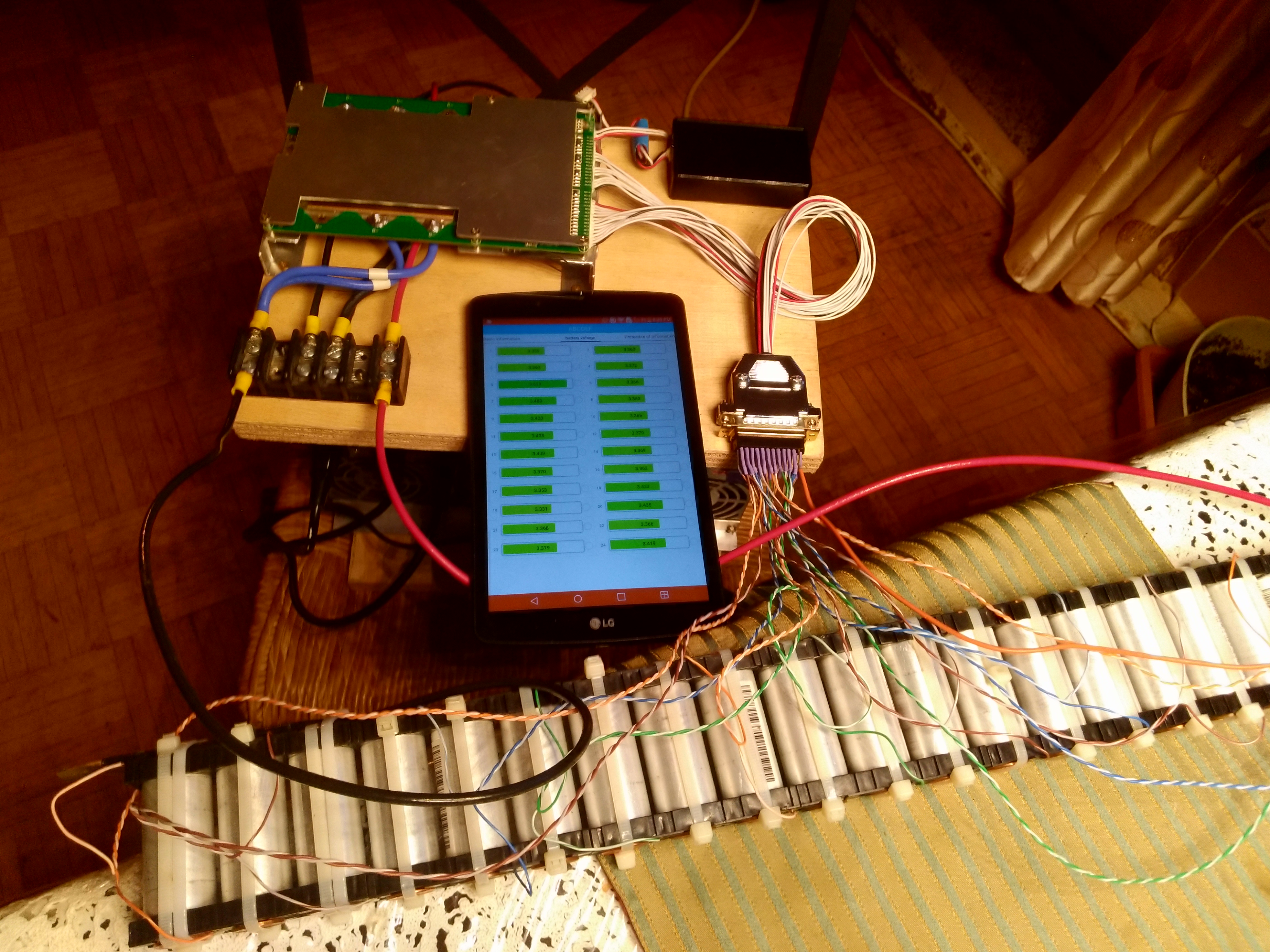

I'm investigating a semi-solderless design where 18650 cells are bought with soldering U tags (8mm x 0.15mm thick pure nickel) already spotwelded but these tags are then attached together to form small 2P groups using M2 or M3 brass bolts. The idea is then first to combine these 2P groups into larger (multiple of 2) parallel groups using a thin copper bus bar (e.g. 0.5mm thick, 10mm wide) and second, make the series connections using thicker copper bus bars (e.g. 1mm thick, 10mm wide). The parallel connection would sit at the bottom while the series connection would sit at the top, with the solder tags from 2 parallel cells sandwiched in-between. Everything being compressed by those M2 or M3 bolts.

This method would involve drilling a 2-3mm diameter (elongated) hole in the nickel strips attached to each cell to accomodate the brass bolt. On a 8mm wide strip, this would leave 6-5mm of nickel thus slightly compromising the current carrying capacity of the strip. On the other hand, the brass bolt is conductive and should compensate for that as it "fills" that hole.

Some advantages:

1) no need to buy a spot welder or solder cells. Cells are bought with U tags already professionally spot welded (e.g by nkon.nl). It is complettely solderless for the user but semi solderless in reality since U tags are spotwelded on the cells.

2) pack can be assembled/rebuilt easily: only involves unscrewing a few bolts and nuts as with the Vruzend kit (less bolts actually, see 3)

3) fewer connection than Vruzend kit (2 cells are joined with only 2 screws while Vruzend would require 4 screws, one on each terminal of each cell)

4) 100% reliable cell contact since the U tags are professionally spotwelded

5) Relatively cheap: only involves a modest fee for buying cells with U tags (+0.5$ per cell). All the rest is easy to find (copper sheet, brass bolts/nuts, cell holder etc) and DIY

Some disadvantages:

1) you need to buy cells with U tags, which may limit vendor choice and slightly increases cell price

2) since one end of the U tag is attached to the cell and the other end is attached to the copper bus bar, the limiting factor for current somehow remains the size of the U tag (no matter how thick the copper bus bars is). On the other hand the length of the tag is pretty short. In my application, each cell should provide max 5A (10S6P with max 30A) so 8mm x 0.15mm U tags appear sufficient.

3) only works for even number of cells in parallel (2P, 4P, 6P etc) but something similar could potentially be done for odd number of cells by using Z tags instead of U tags I guess.

4) requires drilling holes in the nickel strips (U tags) to accomodate the bolts= takes some time but is easy with regular tools.

Some questions:

- Do you see any issue with this design?

- Is the hole compromising anything electrically (structural stability provided by a cell holder)?

- Is an M2 or M3 brass bolt sufficient to provide enough compression for good electrical contact between the copper parallel/series bus bars and the u-tags nickel strips that are attached to the cells? Max tightening torque for such small brass bolts would be pretty low I guess and some threadlock will probably be needed (best would be nylock brass nuts but I don't know if they exist in M2-M3)...

Would be interested to know whether this approach has already been attempted and would be sensible.Thanks!

EDIT: I will add a scheme later on to illustrate the design

I'm investigating a semi-solderless design where 18650 cells are bought with soldering U tags (8mm x 0.15mm thick pure nickel) already spotwelded but these tags are then attached together to form small 2P groups using M2 or M3 brass bolts. The idea is then first to combine these 2P groups into larger (multiple of 2) parallel groups using a thin copper bus bar (e.g. 0.5mm thick, 10mm wide) and second, make the series connections using thicker copper bus bars (e.g. 1mm thick, 10mm wide). The parallel connection would sit at the bottom while the series connection would sit at the top, with the solder tags from 2 parallel cells sandwiched in-between. Everything being compressed by those M2 or M3 bolts.

This method would involve drilling a 2-3mm diameter (elongated) hole in the nickel strips attached to each cell to accomodate the brass bolt. On a 8mm wide strip, this would leave 6-5mm of nickel thus slightly compromising the current carrying capacity of the strip. On the other hand, the brass bolt is conductive and should compensate for that as it "fills" that hole.

Some advantages:

1) no need to buy a spot welder or solder cells. Cells are bought with U tags already professionally spot welded (e.g by nkon.nl). It is complettely solderless for the user but semi solderless in reality since U tags are spotwelded on the cells.

2) pack can be assembled/rebuilt easily: only involves unscrewing a few bolts and nuts as with the Vruzend kit (less bolts actually, see 3)

3) fewer connection than Vruzend kit (2 cells are joined with only 2 screws while Vruzend would require 4 screws, one on each terminal of each cell)

4) 100% reliable cell contact since the U tags are professionally spotwelded

5) Relatively cheap: only involves a modest fee for buying cells with U tags (+0.5$ per cell). All the rest is easy to find (copper sheet, brass bolts/nuts, cell holder etc) and DIY

Some disadvantages:

1) you need to buy cells with U tags, which may limit vendor choice and slightly increases cell price

2) since one end of the U tag is attached to the cell and the other end is attached to the copper bus bar, the limiting factor for current somehow remains the size of the U tag (no matter how thick the copper bus bars is). On the other hand the length of the tag is pretty short. In my application, each cell should provide max 5A (10S6P with max 30A) so 8mm x 0.15mm U tags appear sufficient.

3) only works for even number of cells in parallel (2P, 4P, 6P etc) but something similar could potentially be done for odd number of cells by using Z tags instead of U tags I guess.

4) requires drilling holes in the nickel strips (U tags) to accomodate the bolts= takes some time but is easy with regular tools.

Some questions:

- Do you see any issue with this design?

- Is the hole compromising anything electrically (structural stability provided by a cell holder)?

- Is an M2 or M3 brass bolt sufficient to provide enough compression for good electrical contact between the copper parallel/series bus bars and the u-tags nickel strips that are attached to the cells? Max tightening torque for such small brass bolts would be pretty low I guess and some threadlock will probably be needed (best would be nylock brass nuts but I don't know if they exist in M2-M3)...

Would be interested to know whether this approach has already been attempted and would be sensible.Thanks!

EDIT: I will add a scheme later on to illustrate the design