You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Soldering high current 21700 battery pack from Samsung 30t cells. Is soldering batteries ok in your opinion?

- Thread starter Jacka98

- Start date

you should never solder directly to these cells, there is no better or worse way, just don't do it.

Soldering is acceptable with good procedure. It's becoming a modern myth to say never solder 18650s. Much more can go wrong with spot welding actually until things are dialed in perfectly. Still, spot welding is much more heat in a smaller area.

But I think it is still better to solder with powerful soldering iron with big tip than heating cells with small soldering iron and bad technique. It is hard to weld thick copper strip, so I have been soldering all my high current battery packs.you should never solder directly to these cells, there is no better or worse way, just don't do it.

Is soldering batteries ok in your opinion?

No

Soldering is acceptable with good procedure. It's becoming a modern myth to say never solder 18650s. Much more can go wrong with spot welding actually until things are dialed in perfectly. Still, spot welding is much more heat in a smaller area.

trip, so I have been soldering all my high current battery packs

It is never acceptable! Just don't do it, ok?

It is not a myth, it is a fact and you are 100% damaging your cells. If you are ok with risk and degraded lifetime, do whatever you want.

But I think it is still better to solder with powerful soldering iron with big tip than heating cells with small soldering iron and bad technique. It is hard to weld thick copper strip, so I have been soldering all my high current battery packs.

OFC, it is better to die by jumping from 12th floor than from 5th, but both are horrible right? Just don't solder these cells, end of the story

Like I said - Modern myth that so many have come to believe. (Site some manufacturer research please that says damage occurs form soldering.) The reason spot welders are used by manufacturers is economics. They're fast but not very safe for the novice. We used to endlessly calibrate our spot welders for time, amps and duration and still had issues of repeatability.

I do solder onto the nickel strip at the ends of my builds to attach main discharge, but when I do I;

All that being said, if you are just making a small pack or attaching a single cell and it's only going to be used outside, at very low charge/discharge, then sure, solder away. Just be aware by doing so you are likely damaging/degrading the cells unless all the precautions above are taken.

Cheers

- Crank the iron to the max, and add extra heat with a blow torch to reduce the time it is needed

- Wrap the cells in wet wipes and run a fan to prevent heat build up

- Place lots of kapton tape around the area leaving only the area to be soldered exposed

- Monitor cell temps and stop if they get noticeably hot

- If needed, take occasional breaks to let cells cool

- Solder dripping down into the gap on the positive side and shorting the cell (=instant fireball)

- Heat causing eletrolight to boil, damaging the cell or in a worst case causing the over-pressure to trip the PTC valve or explode the cell. This is particularly bad on the negative side.

- If either of the above happens to just one cell, thermal runaway can occur very quickly for adjacent cells....basically it's an explosion at that point.

- Solder occasionally splashes or drips where you do not want it, ruining the cell heat-shrink or other parts of the construction

All that being said, if you are just making a small pack or attaching a single cell and it's only going to be used outside, at very low charge/discharge, then sure, solder away. Just be aware by doing so you are likely damaging/degrading the cells unless all the precautions above are taken.

Cheers

I do have an American Beauty 3138, and saw that youtube vid on soldering and that looks like a really good solder method for not cooking the cells. I was looking at Kweld to spot weld. Not that I am building batteries at the moment, but I foresee the need to make me a pack that fits me builds. That is, unless I can procure a container load of Metacycles .

.

Eastwood

100 kW

- Joined

- Jan 13, 2021

- Messages

- 1,479

Like I said - Modern myth that so many have come to believe. (Site some manufacturer research please that says damage occurs form soldering.) The reason spot welders are used by manufacturers is economics. They're fast but not very safe for the novice. We used to endlessly calibrate our spot welders for time, amps and duration and still had issues of repeatability.

Sounds like you have the wrong spot welder

Like I said - Modern myth that so many have come to believe. (Site some manufacturer research please that says damage occurs form soldering.) The reason spot welders are used by manufacturers is economics. They're fast but not very safe for the novice. We used to endlessly calibrate our spot welders for time, amps and duration and still had issues of repeatability.

This is another comment that comes from ignorance, spot welders are fine, you don't need to mess with them a lot and are not dangerous at all unless you have some extra shitty one, and they are used because they are the proper method, the one that was designed for these cells, not because it is faster like you say. How many times did you see manufactured pack use soldering? Not even once, that is right. They all use some form of welding, because it doesn't damage the cells unlike soldering (which is 100% does, whatever method you use).

So please stop spreading misinformation on this forum, we have been accumulating knowledge on this topic for over 10 years and now you want to just erase all of that? Won't work, sorry.

Actually we had 13 of them. The cheapest being around $25,000 with the larger production ones costing around $70,000 each. I was operations manager for 13 years.Sounds like you have the wrong spot welder.

So then of course you know it all including if you spot weld you need to be x-rayed before you can get an MRI in a hospital.we have been accumulating knowledge on this topic for over 10 years and now

Chalo

100 TW

Y'all know neither of these processes would be necessary if you're weren't stuck on using toy cells, right?

Just because you only know how to build things out of Lego doesn't mean you should build your house with it.

Just because you only know how to build things out of Lego doesn't mean you should build your house with it.

What cells you then recommend?Y'all know neither of these processes would be necessary if you're weren't stuck on using toy cells, right?

Just because you only know how to build things out of Lego doesn't mean you should build your house with it.

Chalo

100 TW

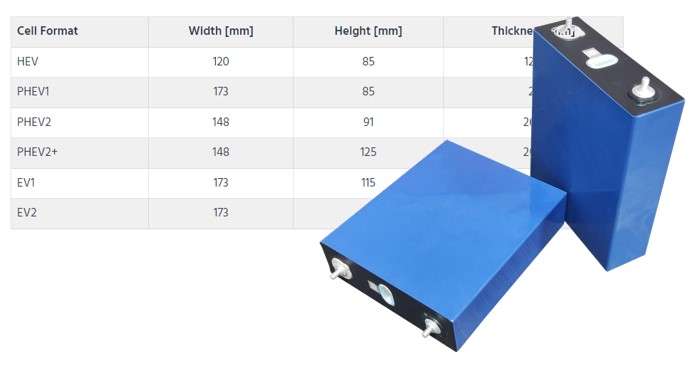

My favorites to work with so far are prismatic cells in PHEV2 format. Those range from mid 20s Ah range to low 50s Ah. Even the high energy ones pack a lot of power, and the high power ones can push mind boggling amps. Almost all of them have some kind of threaded terminals that make building a pack a cinch.What cells you then recommend?

VDA Prismatic Cells - Battery Design

VDA prismatic cells are based on a standard written by the German automotive industry. VDA stands for Verband der Automobilindustrie.

Actually we had 13 of them. The cheapest being around $25,000 with the larger production ones costing around $70,000 each. I was operations manager for 13 years.

So then of course you know it all including if you spot weld you need to be x-rayed before you can get an MRI in a hospital.

Ok I know that you are trolling right now, you can't be serious, this is just pure unhinged BS.

And I don't, unfortunately I had plenty of MRI's. I really don't know where people come up with shit like this, it is really funny but also very sad.

Y'all know neither of these processes would be necessary if you're weren't stuck on using toy cells, right?

Just because you only know how to build things out of Lego doesn't mean you should build your house with it.

How can you call them toy cells, they are the best cells that exist and used in plenty of EV's in all sizes from bikes to cars (and some of the best ones). They are harder to build with than ones you linked ofc, but are better in every other way.

Chalo

100 TW

Toy cells/vape cells/flashlight cells are only as good as their connections, which are total garbage compared to real copper bus bars fastened by bolts or studs. It doesn't matter what's inside the can, if you crippled it by the way you put your pack together.How can you call them toy cells, they are the best cells that exist and used in plenty of EV's in all sizes from bikes to cars (and some of the best ones). They are harder to build with than ones you linked ofc, but are better in every other way.

Toy cells/vape cells/flashlight cells are only as good as their connections, which are total garbage compared to real copper bus bars fastened by bolts or studs. It doesn't matter what's inside the can, if you crippled it by the way you put your pack together.

Ok sure but there are ways around it, and it is certainly not fair calling them "toy cells" since they have the best tech in the world inside.

Chalo

100 TW

Ok sure but there are ways around it,

Laser welding? Ultrasound welding? Certainly nothing I've seen implemented around here. Every time someone says "30A cell", I have to fill in "with 5A connection".

and it is certainly not fair calling them "toy cells" since they have the best tech in the world inside.

Best tech is as best tech does. What toy cells seem to be best at is dying younger than other types.

Laser welding? Ultrasound welding? Certainly nothing I've seen implemented around here. Every time someone says "30A cell", I have to fill in "with 5A connection".

Best tech is as best tech does. What toy cells seem to be best at is dying younger than other types.

Look man I known you since at least 10 years ago and I know that you ar better than this, cmon. Let's stay objective and factual ok, no need for cheap trolling attempts.

Eastwood

100 kW

- Joined

- Jan 13, 2021

- Messages

- 1,479

Actually we had 13 of them. The cheapest being around $25,000 with the larger production ones costing around $70,000 each. I was operations manager for 13 years.

Oh wow! That’s crazy my $300 spot welder from Amazon produces consistent welds but yet you’re $25,000 spot welder can’t produce consistent welds. Somethings not adding up here.

Dude - You really should broaden your horizons a bit. I'm not sure what your problem is but don't be ignorant. Have you never worked in manufacturing? From stainless medical equipment to car frame sub-assemblies there's allot of spot welding that goes on and that's where I worked for a part of my manufacturing career. From almost foil-like material to 12 ga. sheet was what we did especially stainless steel. Production water-cooled spot-welding machines with auto-load/unload and camera inspection push $100,000.I really don't know where people come up with shit like this

@add - ...and x-rays before MRI? It's standard practice in this country for any metal worker or welder. The hospital questionnaire doesn't exempt DIYers. It's on every MRI consent form I imagine. Was on both of the ones I signed.

The MRI for Metal Workers: Hazards and Solutions - Precise Imaging

Even tiny particles of metal on a patient's skin can create health risks during MRI scans. Here's what metal workers need to know.

www.precisemri.com

www.precisemri.com

Last edited:

eMark

100 kW

The union made by a proficient spot welder has lower electrical resistance than soldering ... making it ideal for high current applications. Spot welded connections are generally more mechanically resistant, so they are safer to use in ebike DIY battery packs.

Pros and Cons of Soldering vs Spot Welding Lithium Cells ... Spot Welding Vs Soldering Lithium Cells - Cell Saviors ...

Can You Spot Weld Copper? ... Can Copper Strip Be Spot-Welded on Batteries - Cell Saviors

Pros and Cons of Soldering vs Spot Welding Lithium Cells ... Spot Welding Vs Soldering Lithium Cells - Cell Saviors ...

Can You Spot Weld Copper? ... Can Copper Strip Be Spot-Welded on Batteries - Cell Saviors

Last edited:

The union made by a proficient spot welder has lower electrical resistance than soldering ... making it ideal for high current applications. Spot welded connections are generally more mechanically resistant, so they are safer to use in ebike DIY battery packs.

Pros and Cons of Soldering vs Spot Welding Lithium Cells ... Spot Welding Vs Soldering Lithium Cells - Cell Saviors ...

Thank you! As I said, soldering is acceptable, I never said it was preferrable. For those that read the article there is very little negative stated about solder connections.

Last edited:

Dude - You really should broaden your horizons a bit. I'm not sure what your problem is but don't be ignorant. Have you never worked in manufacturing? From stainless medical equipment to car frame sub-assemblies there's allot of spot welding that goes on and that's where I worked for a part of my manufacturing career. From almost foil-like material to 12 ga. sheet was what we did especially stainless steel. Production water-cooled spot-welding machines with auto-load/unload and camera inspection push $100,000.

@add - ...and x-rays before MRI? It's standard practice in this country for any metal worker or welder. The hospital questionnaire doesn't exempt DIYers. It's on every MRI consent form I imagine. Was on both of the ones I signed.

The MRI for Metal Workers: Hazards and Solutions - Precise Imaging

Even tiny particles of metal on a patient's skin can create health risks during MRI scans. Here's what metal workers need to know.www.precisemri.com

Wow, you are telling me about being ignorant, this is gold

Regarding the MRI, how can you even compare shavings from general metal fabrication to spot welding these this strips on small cells? If you ever actually did it you would know that they are negligible, so this is just another proof that you have absolutely no idea about what you are talking.

Thank you! As I said, soldering is acceptable, I never said it was preferrable. For those that read the article there is very little negative stated about solder connections.

Wait did you even read the linked article or are you just acting dumb again?

"A soldered connection can easily have better electrical characteristics than a welded one, but it comes at the cost of damaging the cell while that extra electrical performance would have provided no real-world benefit. "

"the added strength of the soldered connection comes at the cost of lost capacity due to heat damage from the soldering process. "

"A spot welded battery will be at least an order of magnitude easier to build than a soldered lithium battery "

"It's always better to spot-weld lithium cells vs soldering them. Spot welding is easier to learn because the type of soldering required to solder battery cells is advanced. If done really well, a soldered connection can be electrically stronger than a welded connection, but it comes at the cost of lost capacity. "

Now please tell me, how did you come to the conclusion that soldering is acceptable in any way? Since when is heat damage and lower capacity along with harder to assemble procedure become acceptable in any way? Please tell me, please.

Similar threads

- Replies

- 6

- Views

- 429

- Replies

- 3

- Views

- 1,512

- Replies

- 3

- Views

- 555